09 January 2024|Sandvik CoromantInsight into Tapping tools: Understanding the Structure and Classifications for Mechanical Applications

Tapping refers to the process of creating threads and is commonly used for this purpose. Currently, taps are utilized for producing external threads or creating internal hole threads. Therefore, a tap is considered a tool, while tapping is categorized as an operation within the context of the technological process.

22 December 2023|Sandvik CoromantMastering Workpieces and Chips in Manufacturing and Machining: A Comprehensive Overview

The metal machining process is vital for creating precise metal components through techniques like turning, planing, drilling, milling, and grinding, all involving cutting tools on metal cutting machines. Understanding the difference between "workpiece" and "chip" is crucial; the workpiece is the initial material, while the chips are the final machined product. Exploring the application and benefits of each type in metal fabrication will clarify their nuanced differences.

15 December 2023|Sandvik CoromantDistinguish CNC Lathe Machining Techniques on Common Materials

In the field of Precision Mechanical engineering, there are six primary material groups denoted by the symbols P - M - K - N - S - H, each possessing distinctive properties. As a result, specific machining techniques and conditions are essential when employing CNC turning to ensure the best possible performance.

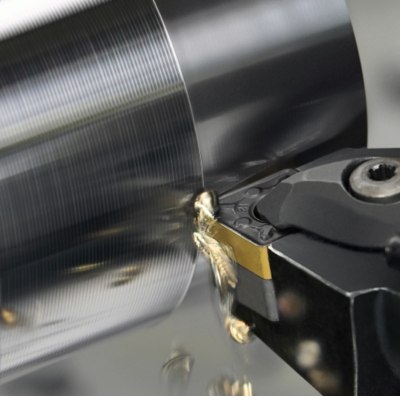

30 November 2023|Sandvik CoromantEssential Guide to Lathe Cutting Tools: Unveiling Inserts, Carbide Chips, and Effective Selection of Carbide Tool Inserts

The turning tool is a cutting tool used on computer numerical control (CNC) lathes to shape components through turning processes. It is a small-sized cutting tool manufactured from high-quality alloy materials.

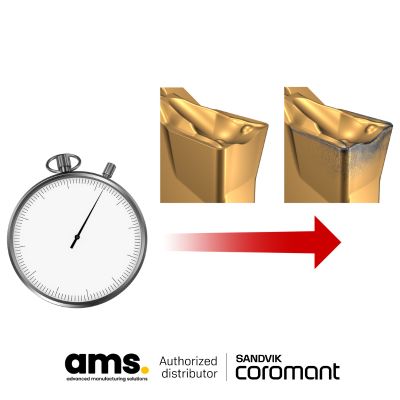

25 November 2023|Sandvik CoromantMaximizing Metal Cutting Tool Longevity: Essential Tips for Maintenance and Optimization

Wear and tear happens when the surface of materials undergoes damage and separation due to sliding, rolling, or colliding movements.

15 November 2023|Sandvik CoromantSuitable drill bit system: The secret to success in mechanical processing

Drilling techniques are widely applied in many industrial fields. Choosing the right drill bit is very important to ensure it meets technical requirements and has the highest economic efficiency.

13 November 2023|Sandvik CoromantDefinition and How to Perform Drilling, Boring, Reaming and Tapping

AMS Company Limited serves as Sandvik Coromant's official distributor in Vietnam. Our knowledgeable sales team is extensively trained and adept at assisting you in finding the ideal Sandvik Coromant product for your drilling, reaming, boring, and tapping applications.

7 October 2023|Sandvik CoromantPCD vs. CBN Cutting Tools: The Differences

Nowadays, PCD and CBN turning tools are widely used on the market. Cutting tool manufacturers have developed their own technologies for the production of their PCD and CBN tool lines.

25 September 2023|Sandvik CoromantTurning in Machining: 3 common types of turning machining you must know

Turning is a very popular mechanical processing method, but not everyone clearly understands this method. During the machining process, many people encounter common problems and errors such as not knowing how to fix it, tools breaking when turning quickly, or turning products that do not meet the desired quality.

15 May 2023|Sandvik CoromantAchieving Precision and Productivity with Sandvik Coromant Milling Cutters

Sandvik Coromant offers a wide range of milling cutters designed to deliver precision and productivity in machining operations. This article will highlight the differences between two popular types of milling cutters: end milling and face milling.

7 May 2023|Sandvik CoromantSandvik Coromant, the World-Leading Cutting Tool Company

With a rich history spanning over 150 years, Sandvik Coromant has built a solid reputation for delivering high-quality and innovative cutting-edge tools to its customers globally.