23 April 2024|KemetHow to increase mold polishing efficiency with Diamond Powder (Part 4)

Through 3 parts, we learned about diamond polishing powders from the Kemet brand. So what is diamond polishing powder made of? Let's learn more details about Diamond Powder with AMS!

19 April 2024|KemetHow to increase mold polishing efficiency with Diamond Powder (Part 3)

Continuing with part 2, we will continue with diamond polishing powders from the Kemet brand - a reputable brand with many quality diamond polishing powder products, providing high polishing efficiency. The products are always trusted and chosen by many customers as the leading solution in polishing various materials.

12 April 2024|KemetHow to increase mold polishing efficiency with Diamond Powder (Part 2)

Kemet is a brand that always receives trust from customers for its quality products, especially Kemet diamond compound products manufactured according to ISO 9001:2015 standards, thereby ensuring high quality. best. As in part 1, we learned about KD type polishing diamond powder and L type mold polishing diamond powder. In part 2, we will learn about OS type polishing diamond powder and CP type polishing diamond powder.

29 March 2024|KemetOptimizing with Diamond Paste: The Ultimate Selection Guide (Part 1)

Kemet diamond pastes blend diamond powder with specific grade and concentration in a carrier, ensuring consistent performance with sorted grains and tailored formulations.

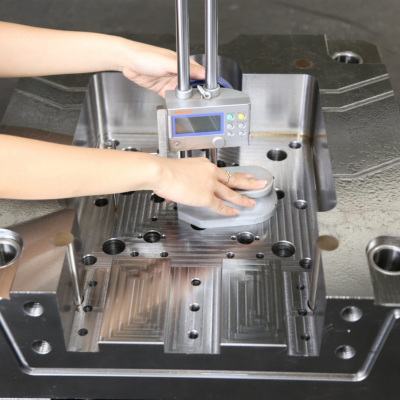

12 September 2023|KemetThe Essential Guide to Mould Polishing Tools: What you need to know

In mould polishing, it is essential to use supporting tools to minimize costs and enhance productivity. By selecting the right tools and utilizing them appropriately, you can optimize the polishing process, achieve desired results, and improve overall efficiency.

28 August 2023|KemetAMS Company Limited: Top Polishing Products supplier in Vietnam's Mould & Die Industry

Here at AMS Company Limited, we take immense pride in being the frontrunners in Vietnam's trading industry for mould and die products, especially when it comes to polishing. With over two decades of experience in serving the precision industry, we have established ourselves as the go-to experts in providing advice and solutions for moulds and dies.

18 August 2023|Kemet5 Common Mistakes with Diamond Compound and How to Fix Them

Here are 5 common mistakes encountered while using diamond compounds for polishing moulds and dies with valuable insights on how to rectify them. By avoiding these mistakes, you can achieve exceptional results and ensure the longevity of your moulds and dies.

10 August 2023|KemetExpert Insights: Unraveling 6 Effective Mould Polishing Techniques

In this article, we will explore six different techniques for mould polishing that professionals in the field widely use. Whether you prefer traditional hand or cutting-edge diamond polishing, we've got you covered!

1 August 2023|Kemet5 Pros and Cons of using Diamond Slurries and CBN Slurries

Diamond slurries and CBN slurries are widely used in various industries, particularly in materials processing and polishing applications. Both slurries offer unique advantages and disadvantages. This article aims to delve into the five key pros and cons of using diamond slurries and CBN slurries, shedding light on their suitability for different purposes.

19 July 2023|KemetLapping and Polishing 101: Understanding the Different Applications for Diamond and Cubic Boron Nitride Slurries

Lapping and polishing are surface-finishing operations used to provide maximum accuracy in size and shape, as well as give the workpiece a smooth and polished finish. This is accomplished by using an abrasive material (e.g. diamond or CBN) suspended in a carrier fluid. When mixed with the appropriate lubricant, this mixture is known as a slurry.