Lapping & Polishing 101: Applications of Diamond & CBN Slurries

Lapping and polishing are surface-finishing operations used to provide maximum accuracy in size and shape, as well as give the workpiece a smooth and polished finish. This is accomplished by using an abrasive material (e.g. diamond or CBN) suspended in a carrier fluid. When mixed with the appropriate lubricant, this mixture is known as a slurry. This slurry is applied with a tool, such as a lapping plate or flat lap wheel, which then grinds away at the surface of the workpiece until it achieves the desired finish. This process leaves behind a perfectly flat surface that has been highly polished, making it suitable for applications needing extreme precision and smoothness.

Each abrasive component (diamond or CBN) has its own unique properties, lending itself to different uses depending on the specific application requirements. Diamond slurries are ideal for machining harder materials due to their extremely high abrasion resistance and cutting power; likewise, CBN slurries are better suited for machining softer metals like steel or aluminium due to their increased toughness and durability compared to diamonds. Both offer an unparalleled level of accuracy available for creating intricate shapes and surfaces requiring precision finishes in industries such as manufacturing, aerospace, optics, and automotive engineering.

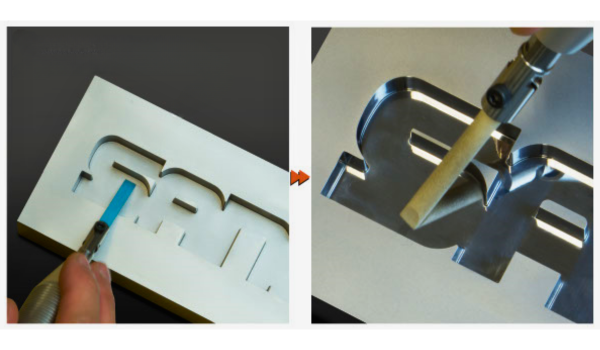

There are numerous different lapping and polishing techniques available to take advantage of these advanced abrasives, with some examples being pad conditioning, flat lapping, vibratory lapping and polishing, and more. In pad conditioning, diamond or CBN slurry is applied directly onto a lap plate surface in order to condition it before the finish-machining process is started. Flat lapping involves passing a continuous flat polished object over a rotating lap wheel coated with the slurry to achieve a desired finish. Vibratory lapping and polishing entail vibrating a flat piece between two laps that have been magnetically charged with the abrasive slurry mixture.

1. Introduction to Lapping and Polishing

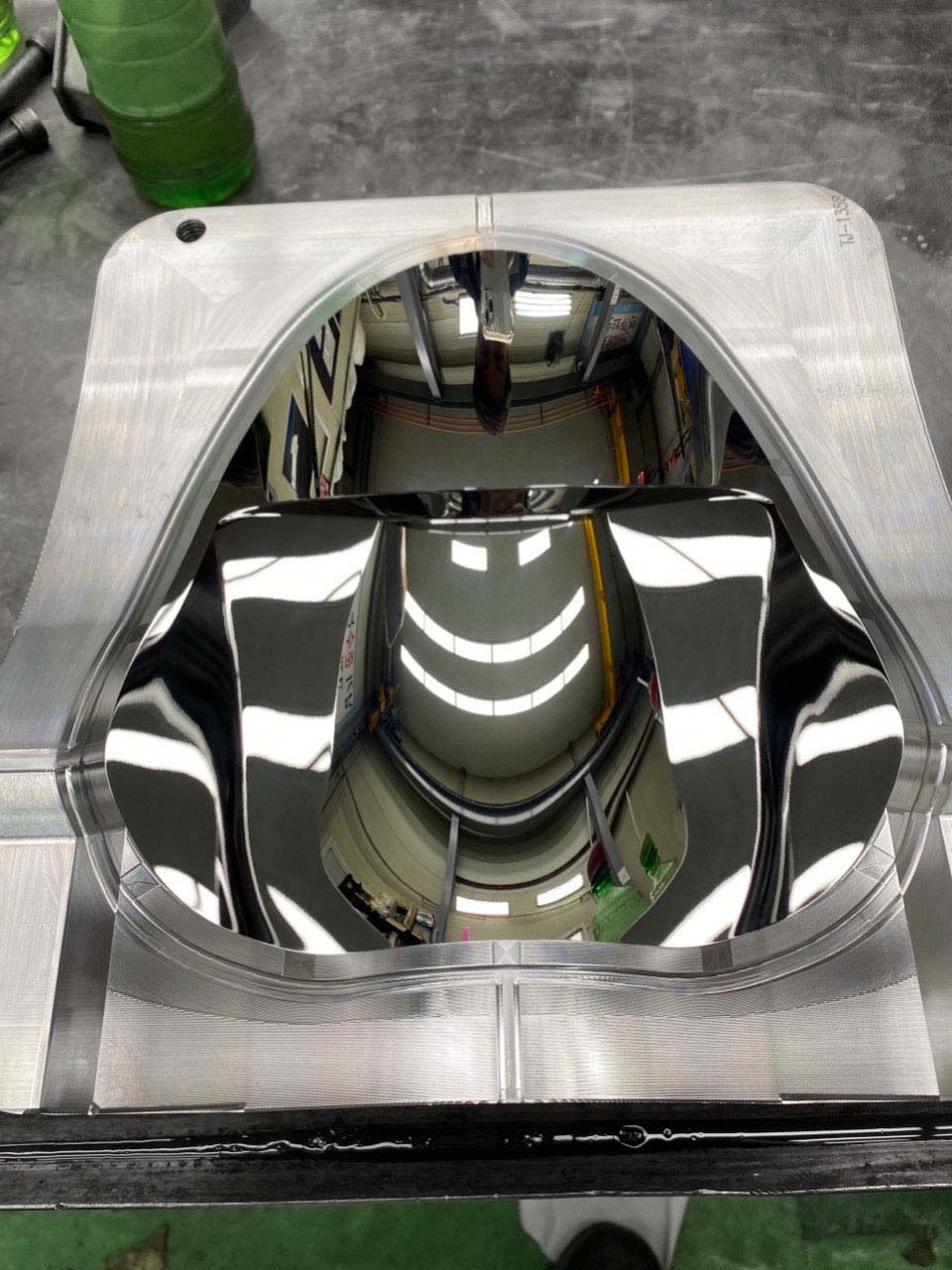

Lapping and polishing is a process where two surfaces are rubbed together with an abrasive material between them. The abrasive material usually consists of small particles of diamond or cubic boron nitride (CBN). Lapping is used to create a smooth, flat surface on the workpiece. Polishing is similar to lapping, but the goal is to create a mirror-like finish instead of a flat surface.

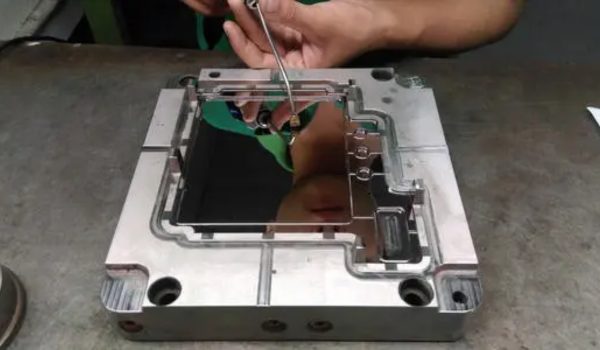

Lapping and polishing can be used for a variety of applications, including preparing surfaces for optical components, semiconductor devices, and angular contact bearings. The type of slurry (abrasive material) used will vary depending on the application. For example, diamond slurries are typically utilized for lapping hard materials such as ceramics, while CBN slurries are better suited for polishing soft metals.

In general, lapping is done using a coarser grit size and larger particle size than polishing. This is because the goal of lapping is to remove Material defects; Whereas the goal of polishing is to create very high optical transparency or surface roughness.

2. Different Applications for Diamond and Cubic Boron Nitride Slurries

There are a variety of diamond and CBN slurries available on the market, each with its own unique set of properties. Depending on the application, different slurries may be better suited. For example, for polishing hard metals, a powdery slurry with small particles is typically used, while for lapping softer materials, a gel-like slurry with larger particles can be more effective.

Some common applications for different types of diamond and CBN slurries include:

- Polishing: For polishing hard metals such as stainless steel or titanium, powdery diamond slurries with small particles are typically used. These slurries can quickly remove scratches and other imperfections from the surface.

- Lapping: Gel-like diamond or cubic boron nitride slurries with larger particles are often used for lapping softer materials such as glass or aluminium. These slurries can provide a smooth, even finish.

- Cutting: Coarser diamond or cubic boron nitride slurries may be used for cutting applications. These abrasive powders can quickly remove material from the workpiece.

- Grinding: Normally, diamond or cubic boron nitride suspensions are used for grinding applications. These fluids can easily remove material without damaging the workpiece.

- Finishing: For a high-quality finish on the workpiece, diamond compounds with small particles are typically used. These slurries can polish the surface to a mirror-like sheen.

3. How to Select the Right Polishing Product for Each Application

When it comes to polishing, there are a few different products on the market that can be used. Depending on the application, different products may be better suited. For example, when polishing metals, diamond slurries are often used. This is because diamond is one of the hardest materials and can cut through metal without damaging it. Cubic boron nitride (CBN) slurries are also available and can be used for a variety of applications, including polishing metals. However, they are not as effective as diamond slurries and should only be used if absolutely necessary.

For polishing plastics and composites, water-based and oil-based polishing creams are often used. Similarly, waxes can be used for buffing out scratches on polished surfaces. These products are great for creating a glossy finish on the surface. However, they do not provide the same level of cutting power as diamond slurries or CBN slurries so if a more aggressive cut is needed then these should be avoided.

When polishing glass and ceramic surfaces, diamond pastes are usually the product of choice. They provide a higher level of cutting power compared to water-based and oil-based creams but are still gentle enough to use on delicate materials. Also, they can be very effective for removing scratches from optical surfaces. For more information regarding specific products, it is best to consult with an expert or manufacturer before selecting one for use in any given application.

4. The Benefits of Using Diamond and Cubic Boron Nitride Slurries

1. Diamond and cubic boron nitride (CBN) slurries offer many benefits when used for lapping and polishing operations.

2. Diamond slurries provide a fast-cutting action and can be used on all types of materials, including complex and brittle materials.

3. CBN slurries are ideal for finishing operations on ferrous metals and alloys.

4. Both diamond and CBN slurries can be used for wet or dry applications.

5. Diamond and CBN slurries are available in a variety of grit sizes to suit specific application requirements.

>> See more: Explore the standard mold polishing process

5. Tips for Maximizing Efficiency with Lapping and Polishing

There are many different ways to use diamond and cubic boron nitride slurries for lapping and polishing purposes. However, not all methods are created equal in terms of efficiency. In order to get the most out of your diamond or cubic boron nitride slurry, it is important to follow some basic tips.

1. Use the Appropriate Abrasive: The first step in maximizing efficiency with lapping and polishing is to select the appropriate abrasive for the job at hand. Depending on the material you are working with and the desired results, you will need to choose between diamond and cubic boron nitride slurries.

2. Choose the Right Concentration: Once you have selected the correct abrasive, it is important to mix it at the proper concentration. If the slurry is too concentrated, it can cause excessive wear on your tools and equipment. On the other hand, if the slurry is too dilute, it will simply be ineffective.

3. Adjust Your Technique: Depending on the specific application, you may need to adjust your lapping and polishing technique. For example, when working with harder materials, it may be necessary to use a coarser grit size or apply more pressure than usual.

By following these simple tips, you can ensure that you are using your diamond or cubic boron nitride slurry in the most efficient way possible.

6. Alternatives to Using Slurries for Lapping and Polishing

In many applications, slurries are not the best option for lapping and polishing. In these cases, other methods may be more effective. Some alternatives to using slurries include:

- Dry lapping: this method uses abrasive pads or other abrasive surfaces to abrade the workpiece. Dry lapping is often used when precision is not as important, or when lapping large surfaces.

- Ultra-laps: ultra-laps use very thin films of abrasive material suspended in a liquid. This method is often used for precision lapping and polishing, as it can produce very smooth finishes.

- Diamond pastes: Diamond pastes are suspensions of diamond particles in a carrier fluid. They are often used for polishing very hard materials, or for creating high-quality finishes.

>> Discover AMS's comprehensive range of polishing solutions now!

7. Conclusion

Lapping and polishing is an important part of the manufacturing process, as it ensures that parts are made to precise dimensions. Knowing which diamond and cubic boron nitride slurries work best for different applications can save time and energy in order to achieve the desired results. The right choice of lapping or polishing slurry will depend on the material being worked on, the desired final surface finish, budget limitations, and other factors. With this knowledge about diamonds and CBN slurries at your disposal, you will be able to make more informed decisions when it comes to achieving perfect results with lapidary projects.

AMS Company Ltd is an experienced distributor of high-quality lapping and polishing products from European brand names in Vietnam. With over 20 years in the field and extensive product range, AMS can provide expert guidance to help you pick the right product for your manufacturing application. Contact us today for more information.

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797