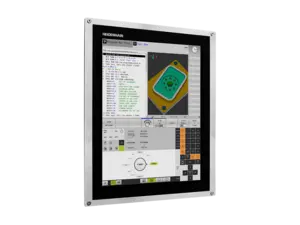

The TNC7 supports users in all scenarios, including programming, machine setup and part measurement. The screen contents are easy to adapt to the given situation, providing complete information and functionality exactly where they are needed. And a special Dark mode feature simplifies operation under low ambient light.

The TNC7 supplements familiar Klartext programming with smart functions. The newly developed graphical programming feature allows the user to draw contours directly on the touchscreen. The TNC7 then converts the resulting drawing into a Klartext program. Older Klartext programs can also be easily modified.

Operating elements such as the TNC keyboard are still used on the TNC7, offering excellent ergonomics even for prolonged work. Older NC programs can continue to be used. Working with the TNC7 is made simpler by a guided introduction to its new functions.

The TNC7 provides intelligently designed solutions, including a rich package of cycles, smart probing functions and graphical guidance for 6D alignment of your workholding and workpieces. Perfect visualization of the machined part and work envelope deliver great convenience to your workday, as do numerous new functions and work methods.

The new Process Monitoring function built into the TNC7 reliably detects irregularities in the machining process and ensures high process quality. The user can adapt this monitoring capability through simple Klartext syntax and an intuitive user interface.

The Component Monitoring feature of the TNC7 can protect the spindle bearing from overloading or detect increased component wear in the drive train, all while the machine is running. It also provides valuable data for predictive maintenance and evaluation of the process capability.

Haven't found the product or technical part number you're looking for?

Please contact AMS for updated information and a detailed quotation.

We offer a comprehensive portfolio of products and can supply solutions tailored to your specific technical requirements.