Whether for counter spindles, driven tools, or C, Y, and B axes, the CNC PILOT offers numerous convenient and high-performing functions. Multi-channel machining even makes it possible to perform various machining steps with multiple slides at the same time.

The TURN PLUS automatic programming function is the fastest route from a design drawing to the finished workpiece. After the contours of the workpiece blank and finished part have been entered, all that remains is to select the material and workholding equipment. TURN PLUS automatically takes care of the rest at the push of a button.

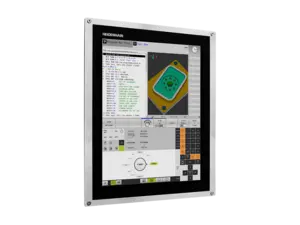

Programming is particularly easy thanks to smart.Turn functionality. All parameters are illustrated by context-sensitive support images and entered in forms. The program's machining blocks are well structured and easy to read.

The CNC PILOT 640 is equipped with an extensive range of cycles. Cycles for turning, milling, and drilling are standard features. Convenient cycle programming is even possible for complex operations such as multiple plunging, simultaneous machining, trochoidal milling, and hobbing.

The complete machining of front and rear sides offers enormous benefits: higher accuracy, fewer errors, shorter run times, and lower costs per part. Programming this is easy thanks to smart functions such as spindle synchronization, traversing to a fixed top, and controlled parting.

The Load Monitoring option monitors spindle and motor loads on the machine, continuously comparing them with load values from a reference operation. As a result, the CNC PILOT 640 immediately detects tool breakage or wear, triggering a predefined reaction.

Haven't found the product or technical part number you're looking for?

Please contact AMS for updated information and a detailed quotation.

We offer a comprehensive portfolio of products and can supply solutions tailored to your specific technical requirements.