The TNC 620 features optimized motion control, short block processing times, and special control strategies, thus attaining very high machining speeds with exceptional contour accuracy, particularly during 3D contour machining.

The ADP function provides effective motion control optimization. ADP dynamically precalculates the contour, adapting the movements based on a jerk-smoothing acceleration limit. Perfect surfaces are attainable even with a highly variable point distribution.

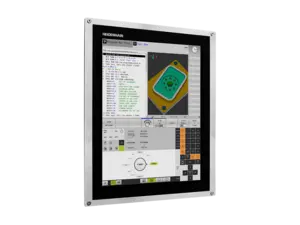

Detailed graphical simulations provide a precise and realistic machining preview, revealing ahead of time whether all required program entries are in place, whether machining operations will run smoothly, and whether surfaces will attain the desired quality.

The OCM option optimizes roughing processes, using special trochoidal milling cycles to machine any countour with high efficiency. Productivity is significantly increased, while tool wear is considerably reduced. The optimal cutting data are determined by an integrated cutting-data calculator.

The Component Monitoring option protects machines by monitoring specifically for failure and damage. Continuous load monitoring of the spindle bearing and feed axes reliably detects wear and effectively prevents overloading.

Dynamic Precision includes multiple functions that improve the contouring accuracy of machine tools, even during high feed rates and complex movements. Precise parts can be efficiently manufactured in short machining times without manual rework.

Haven't found the product or technical part number you're looking for?

Please contact AMS for updated information and a detailed quotation.

We offer a comprehensive portfolio of products and can supply solutions tailored to your specific technical requirements.