This versatile contouring control accommodates the operation of conventional lathes and CNC machines. In manual mode, the machine can be conventionally operated with electronic handwheels. It also features the full range of functions of a CNC turning control.

In teach-in mode, manual machining operations and cycles are performed step-by-step and saved for future parts. As a result, conventional lathe operators without programming expertise can easily get started with CNC-controlled machines.

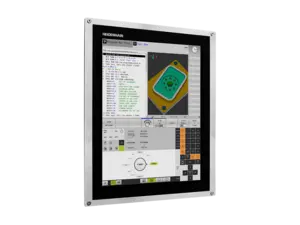

Having a touchscreen makes operation particularly easy: you use gestures to zoom and rotate the simulation graphics; swipe to switch between soft key rows; and navigate through programs, tables, and menus. Intuitive touchscreen operation takes you there faster.

The detailed simulation graphics enable a precise and realistic machining preview prior to machining, revealing whether the program has all required entries, whether machining operations will run smoothly, and whether surfaces will attain the desired quality.

The TURN PLUS automatic programming function is the fastest route from a design drawing to the finished workpiece. After the contours of the workpiece blank and finished part have been entered, all that remains is to select the material and workholding equipment. TURN PLUS automatically takes care of the rest at the push of a button.

The degree of automation can be increased as desired, from simple machining to full CNC capability. The intuitive operating interface of the MANUALplus 620 supports the relevant operating modes. Support images and informative dialog guidance simplify programming. Contours can be programmed interactively or imported as DXF files.

Haven't found the product or technical part number you're looking for?

Please contact AMS for updated information and a detailed quotation.

We offer a comprehensive portfolio of products and can supply solutions tailored to your specific technical requirements.