What is Diamond Powder Polishing?

Diamond powder is a name that creates waves in many different industries because of its presence, with benefits that are more than what people usually think of diamonds, an inherently expensive jewelry. In this article, let's explore with AMS the world of polishing diamond powder, its types, ingredients, applications, and advantages in the manufacturing industry.

1. What is diamond polishing powder?

Diamond polishing powder is known by many different names such as polishing cream, polishing agent, which is an important catalyst compound that cannot be absent in the metal parts manufacturing industry, mold processing and especially the polishing industry. Diamond powder is used to polish all areas that require polishing and finishing the mold surface, it plays an important role in mirror polishing, a level of polishing that must be called the most perfect, requiring the highest surface gloss for the surfaces of mold blanks and metal parts.

Diamond polishing powder is often used in combination with polishing felt or felt grinding heads when used with pneumatic grinders or electric grinders. The above polishing materials play an important and indispensable role in the mold finishing process. Polishing has affirmed its role in the mold industry, and diamond polishing powder alone can be said to be a revolution in value and benefits for all manufacturers.

>> See more: How to use Diamond Polishing Powder

2. Composition of polishing diamond powder

Today, synthetic diamond powder becomes popular due to its consistency, availability and sustainable supply. Unlike natural diamond powder, synthetic diamond powder is created through scientific research, in a harsh artificial laboratory condition such as simulating the high pressure, high temperature environment similar to the conditions for natural diamond formation.

The following are the components of diamond polishing powder:

-

Diamond powder: Diamond particles of extremely small size are the main component, used to abrade and polish surfaces. Depending on each specific application, people will use particles of different sizes.

-

Liquid or solvent (Carrier liquid): To make diamond powder easier to use, people often use water, oil or special solvents to disperse diamond particles, depending on the surface material, use the appropriate solution.

-

Additives: Additives to improve polishing efficiency or protect the surface, such as anti-corrosion agents or coolants.

3. Diamond powder classification

Currently on the market, there are many types of diamond powder from different brands such as Kemet, Hyperion, Misumi,... with a variety of price segments, from low to high with quality suitable for the price. However, before buying, you need to know how to classify diamond powder to suit your needs to have the most optimal and standard purchase choice.

3.1. Classification of Diamond Powder Based on Crystal Structure

Monocrystalline Diamond Powder (MA): This type has compact cubic-shaped crystals, with sharp, protruding edges that result in deep and well-defined cuts, giving it excellent abrasive capabilities. However, its uneven particle size presents a drawback, as surfaces may require additional finishing due to the varying depths of scratches caused by the irregular particle sizes.

Polycrystalline Diamond Powder (PC): PC diamond powder has larger particles compared to MA. The cuts created by PC diamond are generally smaller and more consistent due to its spherical, multi-faceted polyhedral shape. PC diamond powder is suitable for hard surfaces such as sapphire. Its brittle nature under high pressure reveals new cutting edges, allowing multiple cutting actions and resulting in a highly polished surface.

BA Diamond Powder: This type is a more economical and cost-effective option due to its irregular crystal shapes. It is typically used in applications where high precision is not required.

3.2. Classification of diamond powder based on the purpose of use

Using the grinding process (Grinding, Rapid Stock Removal): The purpose of using diamond powder for this stage is to quickly remove large scratches on the surface and wear the surface of the abrasive material as quickly as possible. The perfect diamond powder size for this purpose is about 90 - 25µ, depending on the thickness of the material layer to be worn away.

Used for the polishing process: 2 stages

-

Rough polishing (Lapping and Pre-polishing): The rough grinding process often causes extremely clear scratches, the crystal size chosen for this stage is about 14 - 6µm. At 6µm, it is considered a fairly good gloss, for surfaces that do not require high gloss, this is considered the final stage

-

Final Polishing: Grains with a size of 3 - 0.03µ are used for the final polishing stage in the polishing cycle. At this stage, some solutions are used to lubricate and reduce friction for the polishing process, so the surface will be finished well and have fewer scratches.

3.3. Classification of Diamond Powder Based on Application

For Industrial Use: For flat grinding and polishing industrial molds, it is recommended to use diamond powder from reputable brands that guarantee quality, such as Kemet and Hyperion. Kemet and Hyperion products offer competitive pricing, European quality, and optimized costs in the Asian market, making them widely used.

For Laboratory Sample Analysis: Diamond powder used for grinding and polishing SEM/TEM analytical samples in laboratories requires extremely high precision and uniformity. These powders are typically much more expensive than those used for industrial purposes.

4. Applications of Diamond Powder in Industries

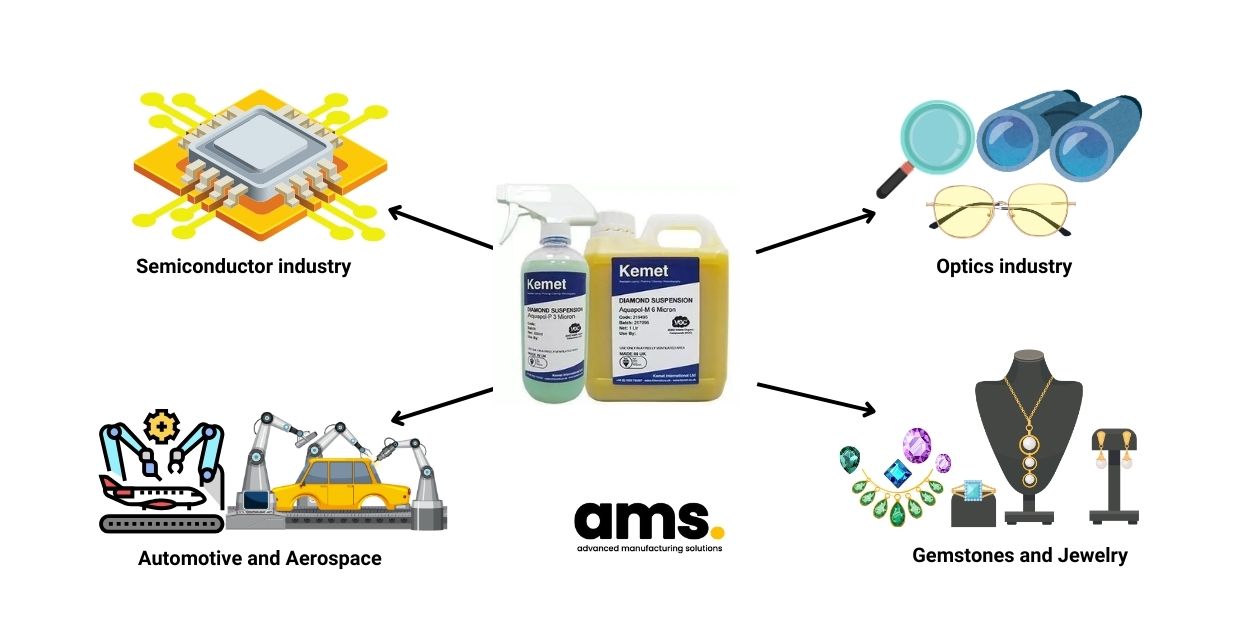

Diamond powder is widely used in many fields, from industry, science and technology to cosmetics, ... and more. However, one of the most important applications of diamond powder is polishing. It is especially applied and most clearly demonstrates its importance in industries such as automobiles, aerospace and electronics for precision machining and finishing of components.

-

Optics: Lenses, mirrors and other optical components benefit from the precision polishing of diamond powder.

-

Electronics (Semiconductor): Silicon wafers and semiconductor materials are polished with diamond powder to create the ultra-smooth surface needed for microchip manufacturing.

-

Automotive and Aerospace: High performance engine components and precision parts are polished with diamond powder to reduce friction and improve efficiency.

-

Gemstones and Jewelry: Diamond powder is used to polish diamonds and gemstones, bringing out their natural brilliance.

5. Advantages of using diamond powder in polishing

It is not by chance that diamond powder is chosen and trusted, especially in polishing. Here are some typical benefits:

-

Achieve a higher level of smoothness and shine

-

Faster polishing time compared to other abrasives

-

More durable polishing tools thanks to the durability of diamonds

-

Ability to effectively polish extremely hard materials

>> See more: Expert Insights: Unraveling 6 Effective Mould Polishing Techniques

6. Conclusion

Diamond polishing powder has become an indispensable material in modern industry. With advancements in materials science, diamond powder will not stop there—it will continue to be researched and developed for new applications and future potential. One thing is certain: diamond powder will be a key partner for manufacturers in their journey toward sustainable development in the future. Therefore, it is essential to choose a reliable, high-quality, and flexible diamond powder supplier that can accompany your business during this era of rapid production and business growth. Contact https://amsvn.com/ today!

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797