Norton Solutions for Body-in-White: Optimize Automotive Manufacturing Performance

Achieving a flawless surface, minimizing rework, and optimizing costs are critical challenges in the Body-in-White (BIW) stage of automotive production. This article explores the polishing and grinding needs during car body processing, offering practical guidance for engineers and procurement teams to make informed purchasing decisions. AMS provides expert insights to help manufacturers select the most effective Norton solutions.

1. What is Body-in-White (BIW)?

Body-in-White is the stage in automotive manufacturing after the individual metal panels have been shaped but before assembly. It forms the foundation for subsequent processes such as electrocoating, primer, paint, and clear coat.

The quality of the surface before painting is crucial. Undetected defects will become highly visible once painted, compromising aesthetics and making the vehicle unacceptable.

BIW involves two essential metalworking processes:

-

Rough Grinding Removes excess material, smooths metal edges, and blends misaligned joints.

-

Metal Finishing: Eliminates small defects created during stamping or grinding, commonly found on hoods, roofs, doors, fenders, side panels, and trunk lids.

>> See more: Expert Guide: How to Choose the Right Grinding Wheel for Your Material

2. How to Select the Right Norton Grinding Solutions by Application

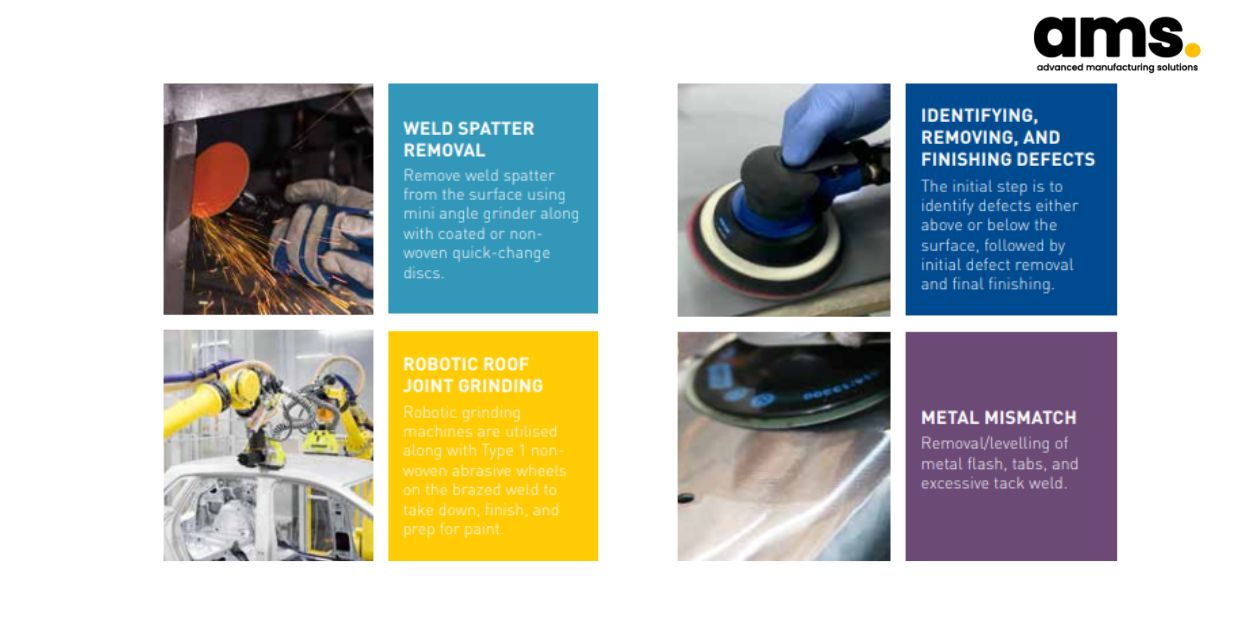

2.1. Identify Initial Surface Defects

Detecting defects early in the BIW process is vital. These imperfections—either raised or recessed must be made visible for subsequent correction. This step is not about fixing defects immediately but preparing them for effective removal.

Recommended Norton solution:

-

MESHPOWER™ CERAMIC M920 - Available in discs, scrolls, and cut sheets. This premium-grade product delivers high performance and cost-efficiency.

Alternative options:

-

SNAKE DIAMOND HAND PADS: Offers comparable quality and performance.

-

GENERAL PURPOSE NON-WOVEN HAND PADS: A reliable option for customers seeking improved performance without using premium-grade products.

2.2. Removal and Surface Finishing

Manufacturers aim to choose products that balance cost with performance. BIW production demands precision and flawless surfaces, making high-end solutions essential.

Top Norton products for defect removal and surface finishing:

-

BLUE FIRE DISCS NORZON H835

-

MULTI-AIR® BLAZE PAPER DISCS A995

-

MULTI-AIR® PLUS PAPER DISCS A975

-

NORaX® DISCS U254

These solutions ensure long tool life, high performance, and excellent material compatibility.

2.3. Correcting Metal Mismatch

Metal mismatch involves addressing uneven surfaces, excess flash, misaligned joints, and protruding tack welds. This stage requires aggressive cutting and high material removal rates, so operators must maintain continuous tool movement.

Recommended Norton solutions:

-

X-TREME FLAP DISCS R860

-

NORTON QUANTUM® FLAP DISCS R996

-

BLAZE® QUICK CHANGE DISCS R980P

-

BLAZE® MINI FLAP DISCS R9R980P

Alternative options:

-

BLAZE®X FIBER DISCS F970X

-

SG FILE BELTS R929

-

RAPID PREP SURFACE CONDITIONING FILE BELTS

2.4. Weld Spot Grinding

Welds joining metal panels are common in BIW production, particularly at hard-to-reach areas, slightly curved surfaces, or small flat zones.

Recommended Norton solutions:

-

BLAZE® RAPID STRIP DEPRESSED CENTRE DISCS TYPE 27

-

BLAZE® RAPID STRIP QUICK CHANGE DISCS

-

VORTEX® RAPID PREP QUICK CHANGE DISCS

-

HIGH STRENGTH BUFFING DISCS

2.5. Robotic Roof Joint Grinding

During assembly, the joints between doors and the roof are brazed, leaving a visible seam that requires grinding and surface preparation before painting. Robotic grinding machines, combined with Type 1 non-woven abrasive wheels, are used to achieve the final finish.

Recommended Norton solutions:

-

VORTEX® RAPID BLEND UNITISED WHEELS

-

RAPID BLEND NEX UNITISED WHEELS

3. Key Considerations When Choosing Norton Solutions

-

Body Material: Steel, aluminum, or alloys influence abrasive type and grain selection.

-

Grit Size: Match to defect severity and finishing stage before painting.

-

Backing & Structure: Paper, cloth, mesh, or non-woven affect conformity on curved surfaces and panels.

-

Dust Extraction & Hole Design: Minimizes dust and prevents paint contamination. Norton Multi-Air offers optimized solutions.

-

Surface Quality Control: Prevent deep scratches, ensure paint adhesion, and maintain uniformity.

-

Total Cost of Ownership: Includes tool life, changeover time, grinding efficiency, and defect rates, not just disc price.

4. Conclusion

Norton solutions for Body-in-White make a significant difference in automotive manufacturing. Selecting the right abrasive for each application from defect removal and weld grinding to final surface finishing allows manufacturers to maximize efficiency, reduce scrap, and achieve consistent surface quality. With Norton, automotive plants gain not only effective products but also time savings, cost efficiency, and improved process stability. Investing in Norton solutions is an investment in precision, quality, and long-term productivity for Body-in-White manufacturing

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797