Explosion - Proof Encoders (Ex-Proof) for the Oil & Gas Industry

Leine Linde explosion - proof encoders (Ex-proof) are widely trusted across global heavy industries, including oil & gas. Contact AMS today to receive expert consultation and select the right encoder for your specific installation position and hazardous environment. Not every position in oil & gas operations requires an explosion-proof encoder. Leine Linde offers a broad portfolio of encoders designed for monitoring speed and motion across various functions, with multiple sizes and durability levels to suit each application. In this article, AMS introduces a robust core solution, the 25 mm incremental explosion-proof encoder and explains why ATEX and IECEx certifications are mandatory in hazardous oil & gas environments.

1. What Is an Explosion - Proof Encoder (Ex-Proof)?

An explosion-proof encoder performs the same fundamental function as standard industrial encoders: converting physical motion or position into digital signals. If you would like a deeper understanding of encoders in general, you can refer to our detailed guide on What Is an Encoder? Structure, Working Principle, and Applications.

Compared to standard industrial encoders, explosion-proof encoders are specifically engineered to:

-

Withstand internal explosions

-

Reduce external pressure through flameproof gaps

-

Prevent sparking, even under extreme high-temperature conditions

These encoders are certified for use in hazardous areas classified as Zone 1, Zone 2, Zone 21, and Zone 22, according to European and IEC standards.

2. Why Are ATEX & IECEx Mandatory Standards?

ATEX and IECEx are two critical certification systems required for electrical equipment operating in explosive (Ex) atmospheres.

-

ATEX is a European directive, mandatory across all EU member states.

-

IECEx is an international certification system required in most countries worldwide that participate in the IECEx scheme.

Leine Linde places strong emphasis on compliance. All products meet both European and international standards, including: ATEX; IECEx; CCC Ex (China). This ensures maximum safety, regulatory compliance, and global applicability.

| European and IEC Classification | North American Classification | Definition of Zone |

| Zone 0 (Gases / Vapors) | Zone 21 (Dusts) | An area in which an explosive mixture is continuously present or present for long periods |

| Zone 0 (Gases / Vapors) | Zone 21 (Dusts) | An area in which an explosive mixture is likely to occur in normal operation |

| Zone 0 (Gases / Vapors) | Zone 21 (Dusts) | An area in which an explosive mixture is not likely to occur in normal operation and if it occurs will exist only for a short time |

| Zone 20 (Dusts) | Class II Division 1 (Dusts) | An area in which an explosive mixture is not likely to occur in normal operation and if it occurs will exist only for a short time |

| Zone 21 (Dusts) | Class II Division 1 (Dusts) | An area in which an explosive mixture is likely to occur in normal operation |

| Zone 21 (Dusts) | Class II Division 2 (Dusts) | An area in which an explosive mixture is not likely to occur in normal operation and if it occurs will exist only for a short time |

3. Technical Challenges in Explosive Oil & Gas Environments

Offshore oil & gas platforms face extreme environmental challenges, including:

-

High humidity and saltwater exposure

-

Dust and contaminants

-

Extreme heat or cold

-

Strong vibration and mechanical shock

Leine Linde explosion-proof encoders are engineered to operate reliably under these harsh conditions, helping prevent unexpected failures and ensuring long-term operational stability.

3.1. Minimizing Downtime

Safety and operational continuity are top priorities in oil & gas operations. Leine Linde Ex-certified encoders are designed to withstand aggressive environments where external factors pose daily operational risks.

Through careful component selection and precision manufacturing, these encoders maximize uptime and performance in critical equipment such as:

-

Top drives

-

Drawworks

-

Mud pumps

3.2. Resistance to Acid and Saltwater

In offshore and marine applications, harsh weather and corrosive environments are unavoidable.

Leine Linde absolute encoders utilize EN 1.4404 stainless steel (AISI 316L), offering excellent resistance to acid and saltwater corrosion. The housing, flange, and shaft are all designed to meet flameproof and corrosion-resistant standards.

This robust construction ensures stable performance in outdoor and offshore installations.

3.3. Preventing Unexpected Failures

Any unplanned failure in offshore oil & gas operations can lead to extremely high costs. Continuous monitoring and preventive maintenance are therefore essential.

Leine Linde Ex-certified incremental encoders feature an integrated Advanced Diagnostic System (ADS).

-

Continuously monitors encoder health

-

Provides early fault warnings

-

Simplifies root-cause analysis

-

Enables proactive maintenance to prevent repeated failures

This helps maintain machine performance and avoid sudden shutdowns.

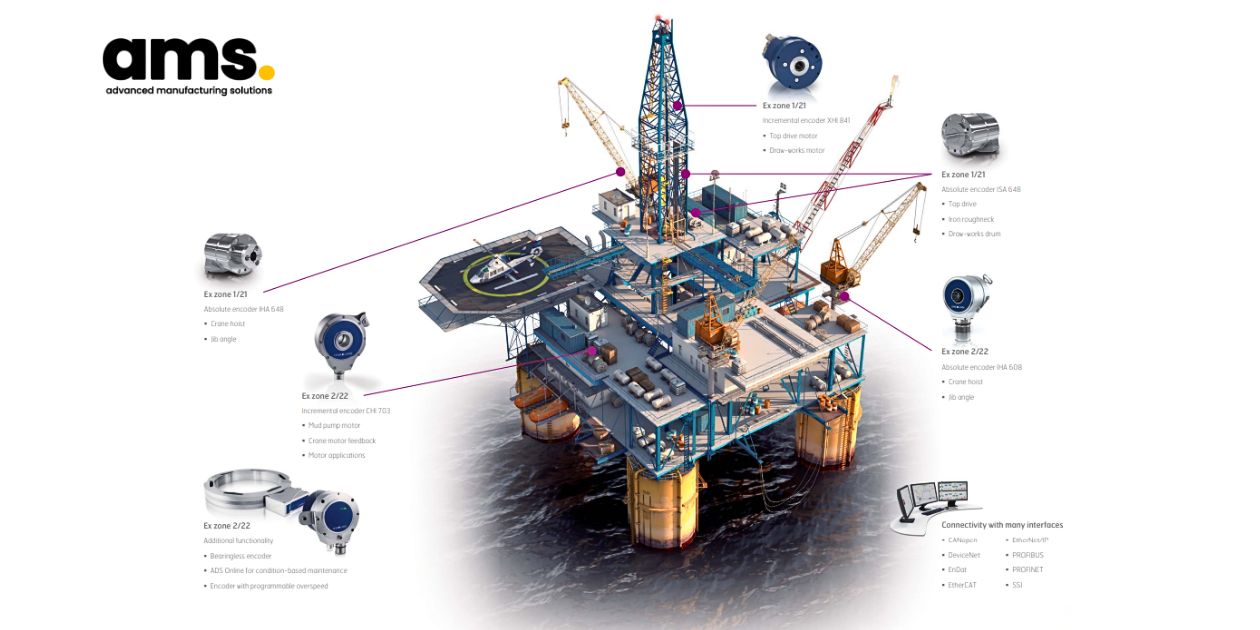

4. Encoder Applications in the Oil & Gas Industry

As mentioned earlier, not all operational areas carry explosion risks. Leine Linde encoders support speed and motion monitoring for a wide range of oil & gas applications, offering multiple sizes and durability options tailored to each use case.

Recommended Explosion-Proof Encoder Solutions.

Based on different hazardous area classifications, Leine Linde provides the following solutions:

-

Hazardous areas requiring Ex Zone 1 / Zone 21 certification: 600 Series absolute encoders; XHI 841 incremental encoders with ADS option

-

Hazardous areas requiring Ex Zone 2 / Zone 22 certification: Robust incremental and absolute encoders; Designed for long service life and resistance to environmental stress; Optional additional features available

>> See more: Explore more Leine Linde encoder products here.

5. Conclusion

Selecting the right explosion-proof encoder and installing it in the correct machine position is critical for safe and efficient oil & gas operations. As an official Leine Linde distributor, AMS is proud to support customers in offshore oil & gas and marine industries with tailored encoder solutions. If you have any technical questions or need application-specific advice, please contact AMS our technical experts are ready to assist you.

AMS Company, Ltd.243/9/10D To Hien Thanh str, Hoa Hung Ward, HCMC, Vietnam

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797