The Role of Diamond Powder in Polishing Micro Components for Automotive Engines

As the demand for precision in the automotive industry continues to grow, so does the need for high-performance polishing solutions. AMS proudly distributes top-tier diamond powders from the US to help Vietnamese manufacturers access the most advanced surface finishing technologies. This article explores how diamond powder is applied in polishing micro-sized engine parts and why it may be the ideal solution for your process.

1. The Importance of Micro Components in Automotive Engines

A fully assembled car is a testament to complex engineering, intricate design, and precise manufacturing. The real magic lies in how micro components work together in sub-assemblies, each part playing a vital role in ensuring the engine runs smoothly.

Key systems such as the engine, transmission, brake system, and steering must operate in unison. A deeper look into these systems reveals precision interactions: valve timing, fuel injection, piston movement, crankshaft rotation, camshaft action, and air-fuel ignition. All of these processes rely on tight tolerances and surface quality to function effectively.

In performance and racing vehicles, attention to micro parts becomes even more critical. High-precision components include:

-

Engine: camshafts, crankshafts, rocker arms, valves, pistons, connecting rods

-

Brake system: brake discs, pads, drums

-

Drivetrain: clutch disc, gear set, differential

-

Steering system

Each of these parts must be manufactured and polished with extreme accuracy to prevent failure at the system level. Surface smoothness, low friction, high heat resistance, and pressure tolerance are non-negotiable.

Take the clutch and flywheel, for example: smooth contact surfaces are required to transfer torque effectively from the engine to the transmission. Similarly, brake discs must maintain a polished surface to ensure consistent braking performance.

2. Challenges in Machining and Polishing Micro Parts

Polishing ultra-small parts presents a unique set of challenges:

-

Difficulty in clamping or securing parts for grinding or polishing

-

Limited access for conventional grinding machines

-

Some parts require manual or specialized techniques (e.g. ultrasonic, centrifugal, or micro polishing systems)

-

Risk of defects such as scratches, breakage, off-center errors, and dimensional inconsistency

3. Application of Diamond Powder in Surface Finishing

3.1. Why Diamond Powder?

Diamond abrasive powders have revolutionized polishing in various industries, and especially in automotive. But what makes diamond powder so special?

-

Extreme hardness and excellent cutting ability

-

Available in a wide range of particle sizes from coarse to ultra-fine (e.g., 0.25 µm, 1 µm)

-

Suitable for hard materials like alloys, aluminum, cast iron, and sintered metals

Polycrystalline diamond powder is especially ideal for engine component polishing due to its ability to:

-

Achieve tighter tolerances → improves fuel efficiency

-

Ensure consistency in high-speed mass production

-

Extend tool life → minimizes downtime

Whether you're using mechanical, chemical, or hybrid polishing, diamond powder remains a versatile and innovative solution for today's advanced automotive applications.

3.2. How to Use Diamond Powder for Polishing

Our AMS specialists recommend choosing the right diamond grit based on your surface material:

-

Coarse grit for material removal

-

Fine grit for final high-gloss finishes

You can mix the powder with water, oil, or solvents to create a polishing slurry. Alternatively, pre-mixed diamond compounds (pastes) are available for easier use.

3.3. Overcoming Challenges & Selecting the Right Diamond Powder

Cost can be a concern diamond powder is a premium product due to its superior performance and scarcity. While many suppliers offer diamond abrasives, consistent quality is what truly matters.

Using diamond powder requires technical expertise to avoid surface damage like scratches or micro-cracks. Not all materials are suitable for diamond polishing, so understanding material compatibility is essential.

4. Diamond Powder Options from AMS

At AMS, we provide a full range of diamond abrasive solutions available in various particle sizes and formulas to suit your polishing needs.

We also supply essential tools and consumables to support your precision finishing workflow.

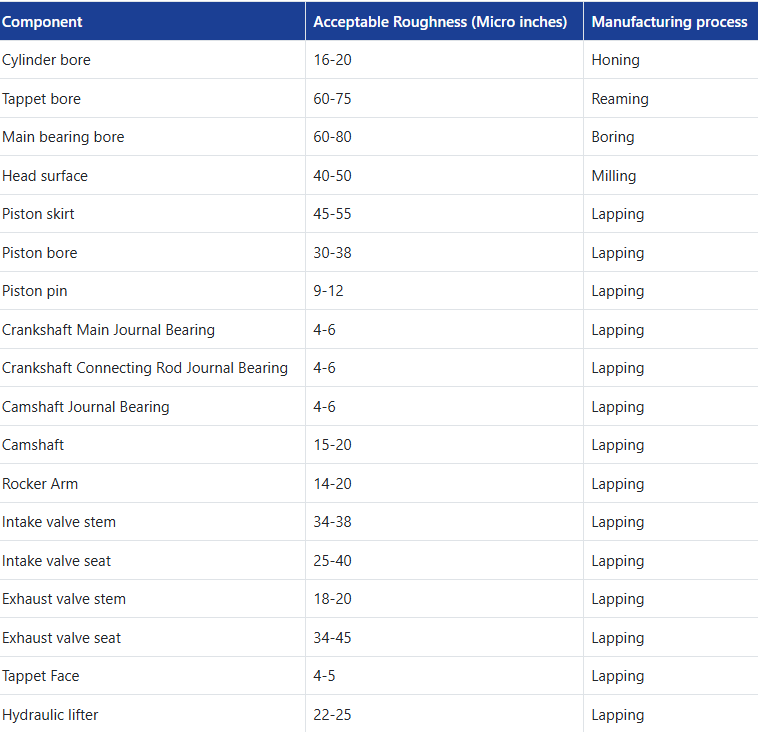

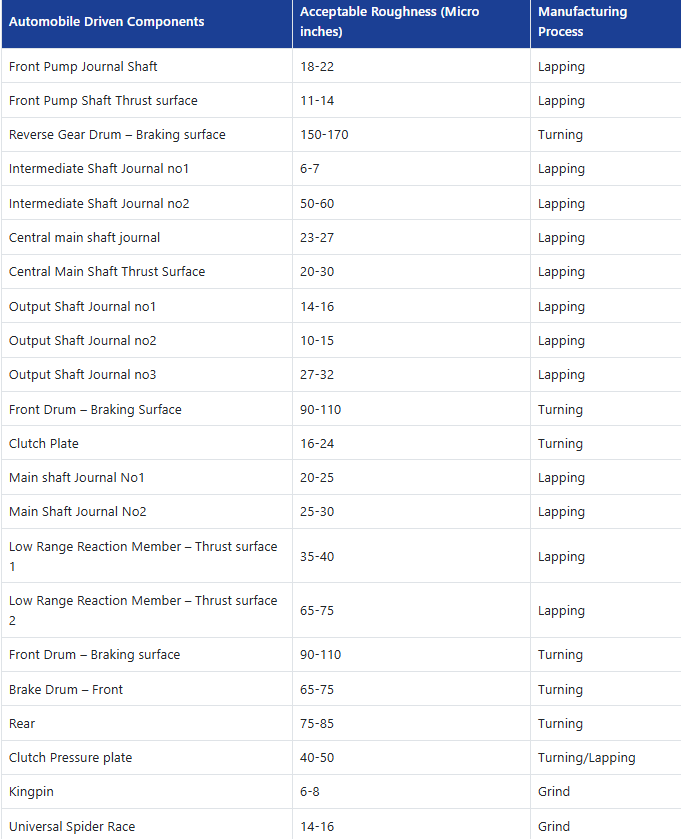

Here are some commonly polished engine components and their standard surface requirements (varies by manufacturer):

5. Conclusion

Diamond powder has become an indispensable tool in polishing micro parts across many industries including automotive engine manufacturing. AMS is proud to offer high-quality diamond products from Kemet, Hyperion, and other trusted brands with clear origin and proven performance.

Let us help you take your engine component finishing to the next level reach out today for samples and expert advice!

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797