Automating the Deburring Process: Efficient Solutions for Modern Manufacturing

Today, with the rapid advancement of science and technology, automation is no longer an unfamiliar concept in manufacturing. Applying automation to the deburring process helps manufacturers reduce processing time and labor requirements while delivering significant technical benefits during surface finishing. This article explains common automated deburring methods and highlights practical applications of XEBEC tools for removing burrs and surface edges in machining operations.

1. What Is Automated Deburring?

Automation refers to the use of machines or specialized equipment to replace traditional, labor-intensive manual processes. Automated deburring is the process of removing burrs generated after machining operations such as milling, turning, or drilling using automated systems instead of manual work.

In the past, deburring was mostly done by hand because it required careful handling depending on burr conditions. However, manual deburring is time-consuming and highly dependent on skilled labor, making it inefficient and difficult to scale. As a result, automated deburring solutions have become increasingly popular in recent years.

2. Advantages of Automated Deburring

-

Shorter processing time

Manual deburring requires significant time, especially in mass production where the workload multiplies. By automating the deburring process and minimizing human intervention, manufacturers can dramatically shorten cycle times.

-

Consistent product quality

Manual deburring often leads to inconsistent quality due to differences in operator skill and applied force. Automated systems deliver stable, repeatable results, simplifying quality inspection and control.

-

Reduced labor costs

Efficient machines require fewer operators. Optimizing manpower through automation helps manufacturers significantly reduce labor costs.

>> Learn more: Case Study: Cutting Polishing Time to 1/3 with a Simple Solution

3. Methods for Automating the Deburring Process

3.1. Automated Deburring Using Machine Tools

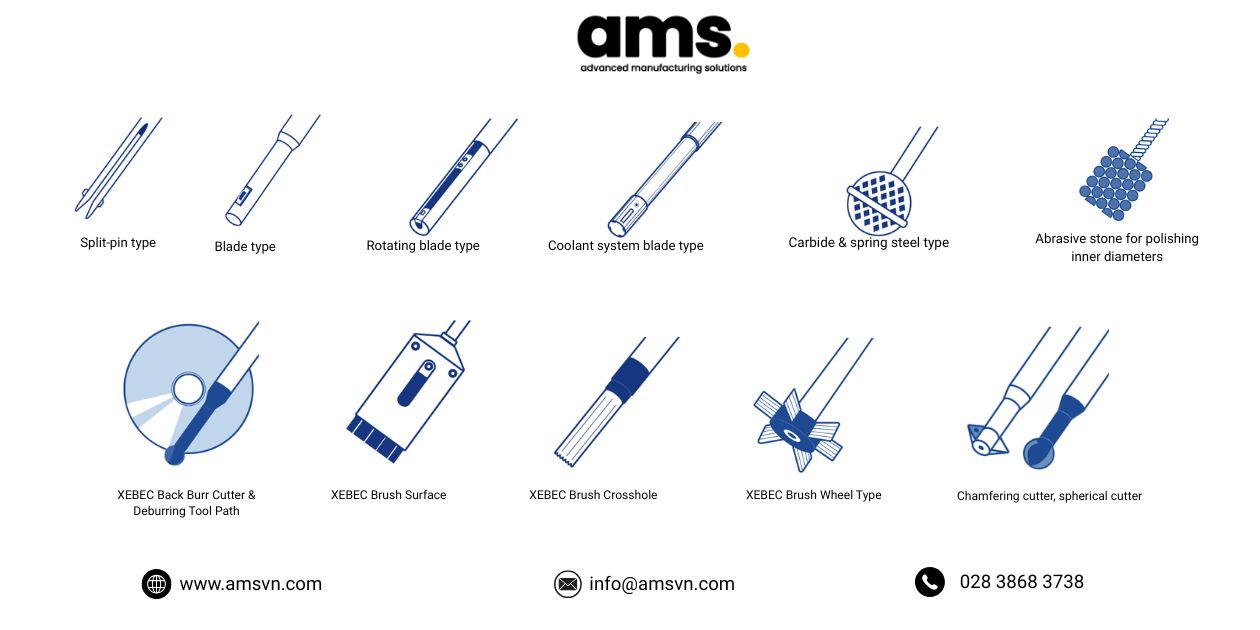

This method uses machining centers or combined lathes equipped with deburring tools such as brushes or cutters to automatically remove burrs during or after machining. Common deburring tools that can be mounted on machines include:

-

Split-Pin Type

A tool with cutting edges shaped like a split pin, functioning similarly to springs. It is mainly used for deburring drilled hole edges (secondary holes). When rotated inside the hole, the blades contact the edge and remove burrs.

-

Blade Type

This tool features a blade pushed outward by spring force. It is primarily used for deburring drilled hole edges, with the elastic force pressing the blade against the burr.

-

Rotating Blade Type

Similar to the blade type, but the cutting blade can rotate freely. When the rotating tool enters a drilled hole, the blade contacts and removes burrs effectively.

-

Coolant System Blade Type

The blade is pushed outward using fluid pressure (typically coolant). It is mainly used for internal diameters and cross holes, removing burrs by contacting internal edges.

-

Carbide & Spring Steel Type

This tool uses a carbide cutting edge supported by a spring steel shaft. It is ideal for deburring drilled hole edges. The spring elasticity prevents chatter during operation.

-

Internal Diameter Polishing Stones

Abrasive stones arranged radially on a nylon base. Used for internal diameters and cross holes, the stones contact internal edges during rotation to remove burrs.

-

XEBEC Back Burr Cutter & Tool Path

A solution combining a specialized cutter with a customized tool path program. Designed mainly for secondary hole deburring, the cutter movement is precisely controlled through tailored CNC programming.

-

XEBEC Brush Surface

A brush made of ceramic fibers with a special sleeve. Used for surface deburring, burrs are removed when the fiber tips contact the workpiece edges during rotation.

-

XEBEC Brush Crosshole

This ceramic fiber brush is designed for internal diameters and cross holes. When rotating, the fibers expand and contact internal edges to remove burrs.

-

XEBEC Brush Wheel Type

Equipped with ceramic fiber bristles and a dedicated shank, this brush is used for surfaces and side edges. Burrs are removed through fiber contact during rotation.

-

Chamfering Cutters & Spherical Cutters

These tools can deburr and round edges in a single machining step, reducing processing time. However, most chamfering and spherical cutters may generate secondary burrs during cutting.

3.2. Automated Deburring Using Dedicated Machines

Although dedicated deburring machines require higher initial investment, they are far more efficient than manual deburring.

-

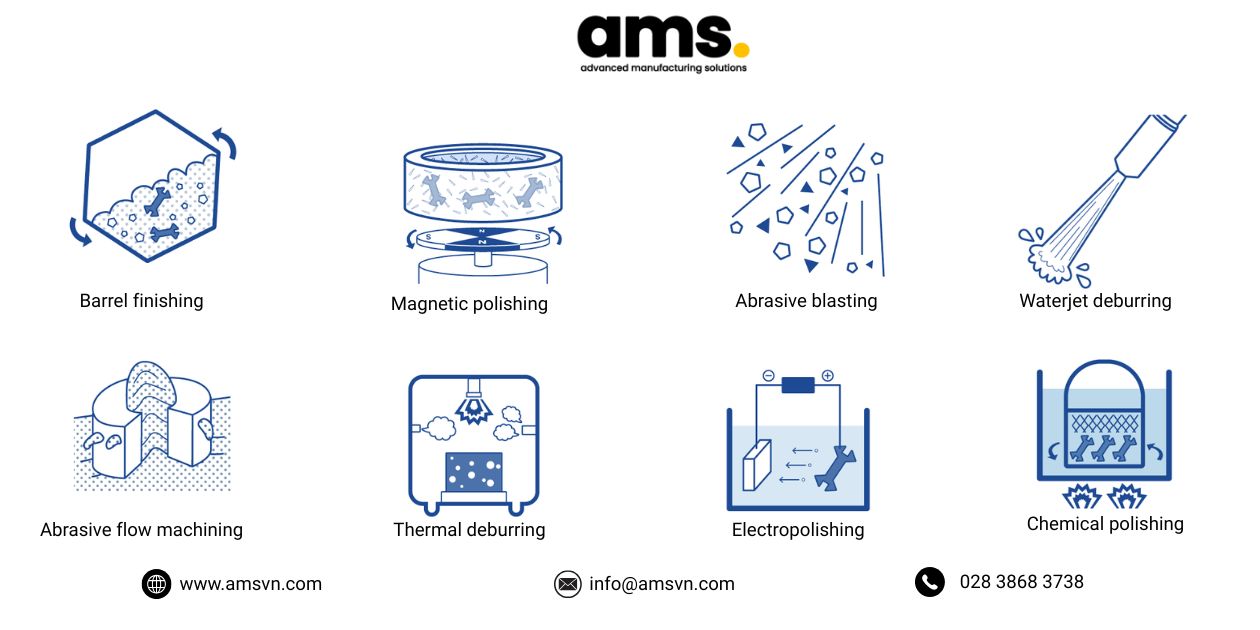

Barrel finishing

Workpieces, abrasive media, water, and compounds are placed in a rotating or vibrating barrel. Burrs are removed through friction between the parts and abrasive media.

This method enables simultaneous deburring, surface polishing, and edge finishing, making it ideal for mass production.

-

Magnetic Polishing

Workpieces, magnetic abrasive media, and cleaning solution are placed in a container and rotated using magnetic force. Burrs are removed through abrasive contact, allowing surface finishing and edge rounding at the same time.

-

Abrasive Blasting

Abrasive particles are projected onto the workpiece surface using centrifugal force. Burr removal is achieved through impact pressure, and the deburring area can be adjusted by controlling the blasting zone.

-

Waterjet Deburring

High-pressure water jets remove burrs from the surface. This method requires simple equipment consisting of a nozzle system and water supply.

-

Abrasive Flow Machining (AFM)

A viscous, elastic medium containing abrasive particles is forced through internal passages of the workpiece. Burrs are removed through abrasion, making AFM highly effective for complex internal geometries.

-

Thermal Deburring

Burrs are removed by combustion. Because heating occurs instantaneously, only thin burrs are burned off while the main workpiece remains unaffected. This method can reach deep areas inaccessible to mechanical tools but requires strict safety control.

-

Electropolishing

Direct current is applied to dissolve burrs in an electrolyte solution, with the workpiece acting as the anode. Due to short processing times, this method is well suited for mass production lines.

-

Chemical Polishing

Polishing solution, alkaline solution, and water are heated, and the workpiece is immersed in the boiling solution. Slight surface dissolution smooths the surface and improves surface finish quality.

>> See more: Where to Buy Genuine Xebec Grinding Stones at the Best Price?

3.3. Automated Deburring Using Robotic Arms

Deburring can also be automated using robotic arms equipped with polishing tools or rotary brushes. As robotic arms become more compact, this solution can now be applied even in facilities with limited space.

However, with current control technology, accurately deburring complex geometries remains challenging. While not yet widely adopted, robotic deburring is expected to become more common in the future.

4. Conclusion

This article provides an overview of automated deburring solutions and highlights practical applications of XEBEC deburring tools. Contact AMS to learn more about selecting the right XEBEC solution for your needs. Let us help you save time, simplify procurement, and ensure on-time delivery.

AMS Company, Ltd.243/9/10D To Hien Thanh str, Hoa Hung Ward, HCMC, Vietnam

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797