Where to Buy Genuine Xebec Grinding Stones at the Best Price?

Xebec grinding stones, diamond powder, diamond compounds, and sandpaper are all common solutions for polishing and material removal. But do you know how to distinguish between these tools and when to use diamond powder versus a Xebec grinding stone? Where can you buy authentic products at the best price?

The AMS team is always ready to provide detailed consultation, helping customers choose the right grinding tool for their specific material surface. Don't miss this article with in-depth information below!

1. Overview of Common Tools Used for Polishing and Grinding

Grinding is a complex machining process that removes unwanted material layers to create smoother, more uniform, and highly precise surfaces. Over the centuries, grinding technology has advanced significantly, along with the development of new materials, tools, and modern machinery.

The demand for polishing and grinding consumables continues to grow as factories expand and machining needs become stronger than ever before. This growth is driven by industries such as automotive manufacturing, semiconductors, electronics, steel, and aerospace. To meet this rising demand, more and more authorized distributors in Vietnam are ensuring a reliable supply of grinding tools with timely delivery.

Grinding can be divided into several basic machining forms:

-

External grinding: for cylindrical shafts, drill tapers, components, etc.

-

Internal grinding: for bores and inner surfaces.

-

Surface grinding: for flat surfaces.

Depending on the surface, shape, size, and material, different grinding tools must be selected to achieve the best results. Choosing the correct tool for each stage is crucial—you cannot use coarse diamond abrasives during the finishing stage without risking damage to the workpiece.

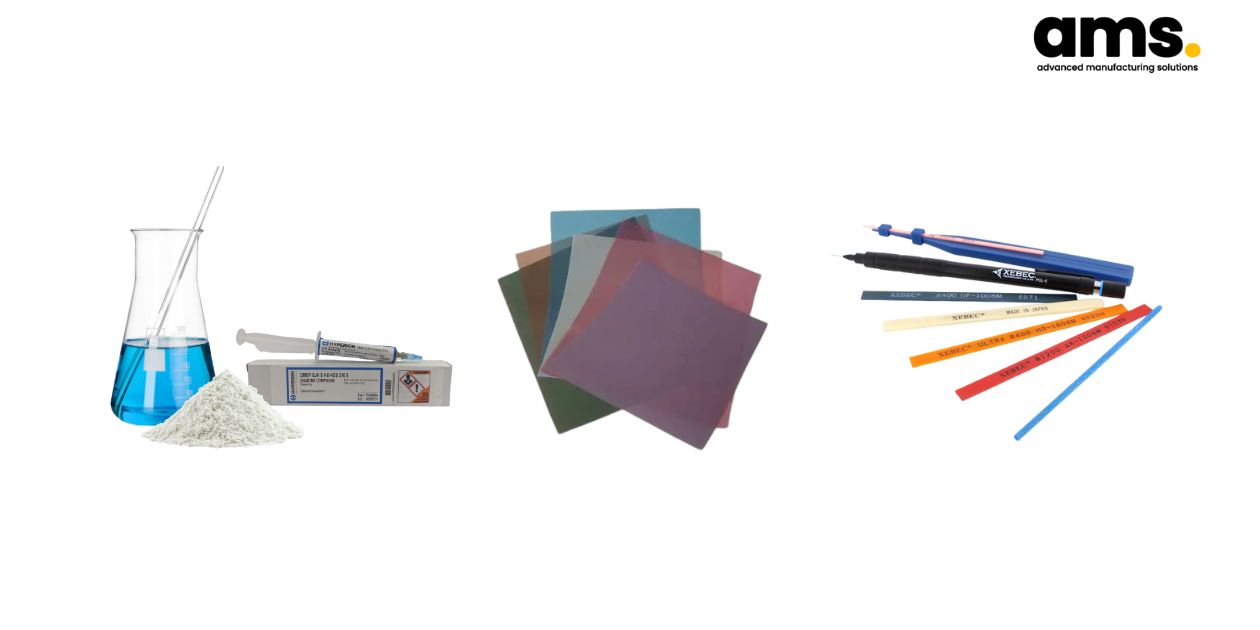

At AMS, our experts introduce some of the most common polishing materials, including diamond powder and diamond compounds, sandpaper, and Xebec grinding stones (collectively referred to as grinding tools). There are also many other tools used in polishing processes, such as felt accessories and Supra MM bristle cup brushes.

However, this article will focus on clarifying three main categories of consumable grinding tools that are especially useful for individuals involved in procurement for manufacturing businesses.

2. What is Xebec ceramic stone?

Xebec grinding stone (Xebec ceramic stone) is a surface refinement grinding tool produced with specially bonded ceramic fiber. Unlike traditional grinding stones that only have abrasive particles concentrated on the surface, Xebec ceramic stones have abrasive particles distributed throughout the entire block → during use, a new layer is always "regenerated", helping the stone to maintain a stable shape and maintain continuous cutting ability. Xebec ceramic stone is the optimal solution for fine grinding in small details, narrow slots and hard materials, where sandpaper or diamond powder is difficult to be effective.

3. Distinguishing some polishing products

3.1. Diamond Powder and Diamond Compounds - The Solution for Super-Finishing

Key Characteristics:

-

Ultra-hard material (diamond): Capable of polishing extremely hard substrates such as carbide, ceramic, tungsten, and sapphire.

-

Super-fine grit size: Typically from a few microns down to sub-micron levels, enabling ultra-high surface finish.

-

Used with soft carriers: Commonly applied with polishing cloths, pads, or flexible bases.

When to Use:

-

During the finishing or super-finishing stage, after rough grinding with harder tools.

-

When a mirror-like surface finish or surface roughness of Ra < 0.1 µm is required.

-

In lapping and polishing of optical molds, medical molds, and semiconductor components.

Example:

After repairing a steel mold with hardness HRC 60, applying 3 µm diamond compound followed by 1 µm achieves a mirror finish.

3.2. Sandpaper - Flexible for Soft Surfaces and Intermediate Stages

Key Characteristics:

-

Abrasive grains typically made of aluminum oxide, silicon carbide, or zirconia.

-

Paper or film backing provides high flexibility.

-

Wide grit range available (P60 - P5000).

When to Use:

-

Ideal for intermediate stages or coarse finishing.

-

Removing light burrs, preparing surfaces before painting/coating, or smoothing softer materials such as plastics, wood, and aluminum.

-

Not suitable for grinding very hard surfaces with tight tolerances.

Example:

Matt finishing an ABS plastic surface before painting, or removing tool marks from aluminum components.

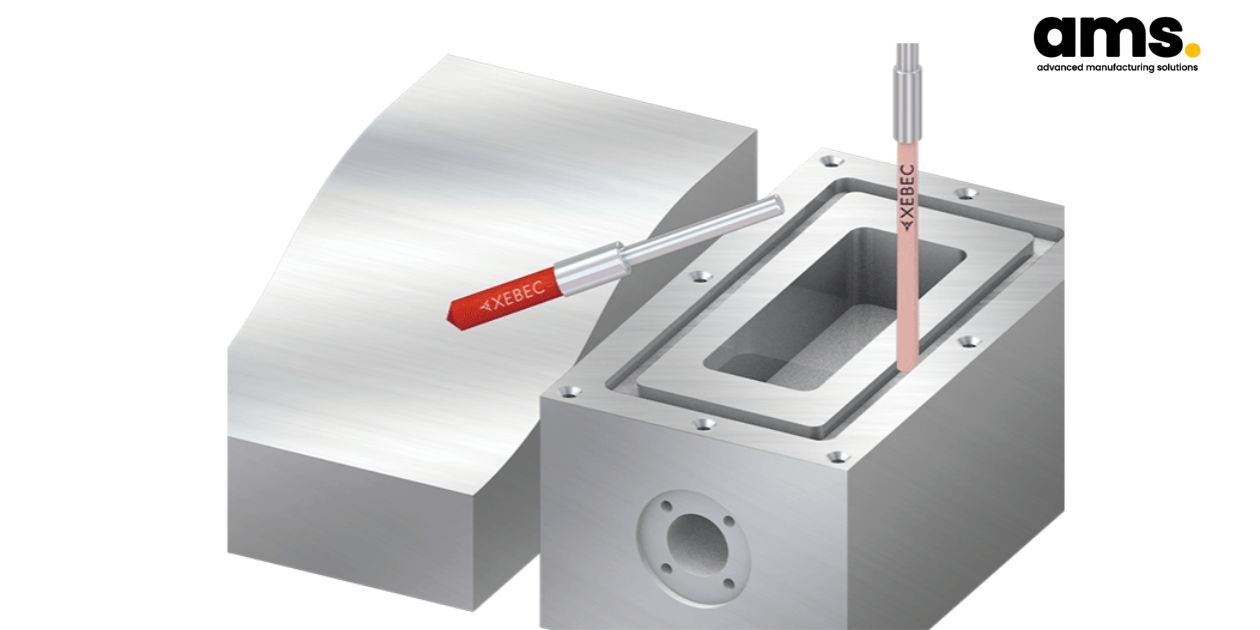

3.3. Xebec Grinding Stones - Precision Finishing for Hard-to-Reach Areas

Key Characteristics:

-

Made of ceramic fiber with a special bonding structure, ensuring abrasive grains are evenly distributed throughout the entire tool.

-

Can cut hard materials while maintaining a sharp, consistent shape for longer.

-

Available in various forms sticks, cylinders, rounded tips, and pointed tips making it easier to access tight spaces and deep grooves.

-

Suitable for both manual use and with pneumatic/electric grinders.

When to Use:

-

For detail finishing, especially in molds with slots, grooves, or sharp edges where sandpaper or diamond compounds cannot reach.

-

To remove EDM scale or smooth CNC-machined surfaces in difficult-to-reach areas.

-

When high geometric accuracy and minimal surface deformation are required.

Example:

Deburring inside an injection mold groove or cleaning EDM traces in deep cavities where sandpaper cannot reach.

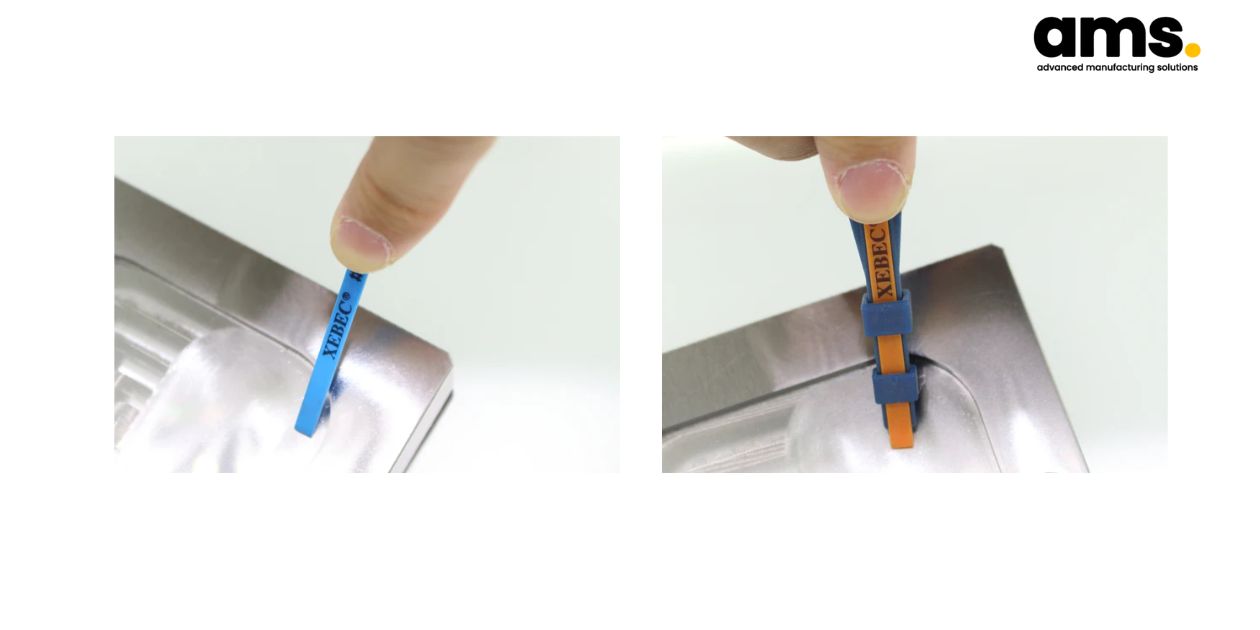

4. Guide to Using Flat-Type Xebec Grinding Stones

1. Correct Holding Position: Press the end of the stone firmly against the work surface at a 45-degree angle.

2. Cutting Power from Ceramic Fibers: Xebec grinding sticks are made from a network of ceramic fibers, which provide cutting force along the sides. They can be used by hand or with a handpiece holder to improve efficiency.

3. Using with Vibratory Tools: For greater effectiveness, Xebec stones can also be used with vibratory tools (electric, ultrasonic, or pneumatic). When using such tools, experts recommend choosing heat-resistant Xebec grinding stones for optimal performance.

5. Successful Case Study with Xebec Grinding Stones

We would like to share a success story from Aoi Seiki, a company specializing in vacuum component manufacturing for the semiconductor industry, which managed to cut polishing time down to just one-third by adopting Xebec grinding solutions.

Their biggest issue was that the manual polishing process could take several hours for just a single component. According to Masakazu Miyanaga, from Manufacturing Group 1, Odasakae Plant, Business Unit 2 at Aoi Seiki Co., Ltd.:

“IC chips are critical parts of semiconductor devices, considered the very core of these systems. Even the slightest deviation is unacceptable, which makes the polishing process extremely important. As a result, workers performing on-site polishing were under significant pressure. In some cases, polishing one component could take up to six hours. If we scheduled deliveries based on polishing time alone, the waiting period became unreasonably long. After introducing the Xebec Brush, polishing time was reduced to just one-third of the original, while also significantly reducing the workload for our staff.”

At the Vietnamese market, AMS has successfully delivered Xebec grinding stones to factory engineers. Our consultation team has also received positive feedback on their precise grinding performance and shape durability, which help optimize fine finishing of glass components and precision molds.

As proof of this effectiveness, we continue to maintain strong relationships with our existing customers supporting them whenever they need replenishment, place new orders, or require additional technical advice.

6. Where to Buy Genuine Xebec Grinding Stones at the Best Price?

In Vietnam, there are many distributors offering Xebec grinding stones. With just one click, you can find thousands of results on search engines and easily purchase the product you're looking for. But at AMS, we believe this is not the only factor that matters to our customers.

AMS is a technical solutions provider with over two decades of experience in the Vietnamese market.

When it comes to polishing solutions, we prioritize precision, optimization, and suitability. Understanding the market demands, customer budgets, lead times, and challenges allows us to deliver the most fitting solutions - ensuring long-term partnerships with our clients.

The products we supply are focused on high quality at a reasonable cost. We are also ready to provide test samples so you can evaluate and select the products best suited to your workflow. Contact AMS today for any of your polishing needs!

7. Conclusion

Xebec grinding stones come in a wide range of product lines and specifications. Save your time by simply describing your application needs to the AMS consultation team. We are committed to providing dedicated support and helping you select the most suitable solution. Thank you for following and trusting AMS!

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797