Don't Miss the Top Smart Manufacturing Trends in 2025

In the booming era of Industry 4.0, advanced technologies are being widely applied across all aspects of science and society, creating inevitable global trends. By 2025, the concept of smart manufacturing is becoming increasingly widespread worldwide.

Don't miss the top smart manufacturing trends of 2025 with AMS, and explore the challenges that Vietnamese manufacturers may face amid global integration. By understanding manufacturers' capabilities, market dynamics, and upcoming trends, AMS believes our customers can effectively build long-term strategies for optimized production.

1. What is Smart Manufacturing?

According to NIST (National Institute of Standards and Technology), smart manufacturing is defined as: “a fully integrated, collaborative manufacturing system that responds in real time to meet changing demands and conditions in the factory, in the supply network, and in customer needs.”

Smart manufacturing leverages advanced technologies such as IoT (Internet of Things), AI (Artificial Intelligence), Big Data, and mobile robotics to optimize production processes and improve efficiency. This enables businesses to be more flexible, precise, and productive in manufacturing, thereby enhancing competitiveness and meeting market demands.

2. Smart Manufacturing Market Overview

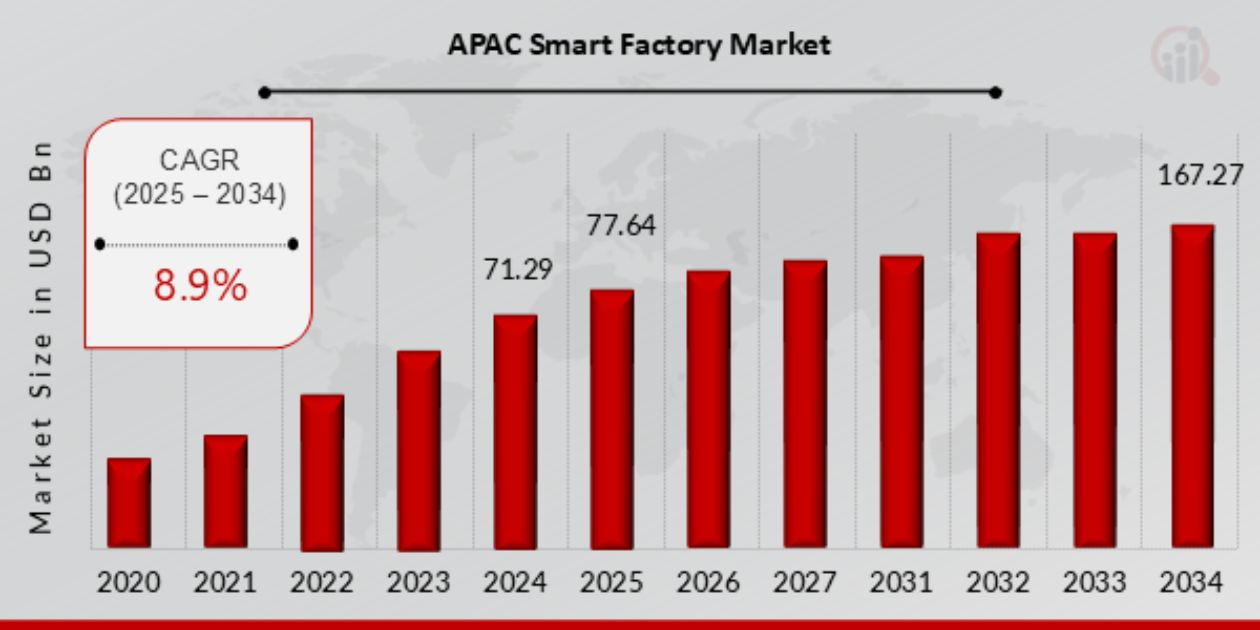

The world has entered a robust transformation era over the past decades, beginning in developed countries and gradually spreading to developing nations. In the Asia-Pacific (APAC) region, the smart factory market is estimated to reach USD 71.29 billion. The compound annual growth rate (CAGR) is projected at 8.9% during the forecast period (2025-2034).

The market's growth is driven by the rising demand for predictive maintenance (PdM) solutions. Predictive maintenance systems utilize advanced data analytics and IoT sensors to anticipate equipment failures, which in turn improves productivity and reduces downtime.

Vietnam has emerged as a bright spot on the Asian manufacturing map. Following a period of rapid growth, the country's manufacturing industry is shifting toward smart manufacturing, gaining a more strategic position in the global competitive landscape.

Vietnam's market is undergoing a positive transformation, with several key indicators:

-

Stronger business investment and operational optimization: Enterprises are investing more aggressively in machinery integrated with smart technologies and focusing on comprehensive solution packages.

-

Government policy support: Amidst a complex global political, economic, and trade landscape, Vietnam holds a competitive edge in attracting foreign investment thanks to 17 new-generation free trade agreements (FTAs) already signed. The government also has ambitious goals for transitioning growth models, reforming institutions and policies in line with international standards, and streamlining state apparatuses for greater efficiency.

“Foreign investors see these advantages as investment opportunities in Vietnam, and the country also has the ability to select projects that align with its FDI attraction strategies at both central and local levels,” said Prof. Dr. Nguyen Mai, Chairman of the Vietnam Association of Foreign Invested Enterprises (VAFIE).

-

Technological advancements: Technologies such as IoT, AI, and robotics are evolving rapidly, accelerating the growth of smart manufacturing. According to the National Robotics Engineering Center (NREC), the number of robots used in manufacturing is expected to continue rising in the future.

3. Current Trends in the Smart Factory Market

3.1. IoT Device Integration for Real-Time Monitoring Is Driving Market Growth

These devices enable seamless communication and data sharing between machines, systems, and workers, creating a highly efficient and responsive manufacturing environment. Real-time monitoring offers numerous benefits, allowing proactive decision-making by enabling instant adjustments to optimize operations, enhance quality control, and ensure timely maintenance interventions.

IoT improves operational efficiency and minimizes the risk of equipment failure and costly downtime.

3.2. Sustainable Manufacturing Trend

The smart factory market is evolving, with a significant rise in emphasis on cost-reduction measures and waste minimization. Industries increasingly recognize the need to optimize resources and streamline processes to remain competitive in a globalized environment.

Smart factories offer an integrated approach by combining sophisticated technologies such as Artificial Intelligence, IoT, and data analytics to enhance efficiency and productivity while lowering costs and waste. Implementing sustainable practices within smart factories aligns with broader environmental initiatives, attracting environmentally conscious customers and complying with regulatory standards, ultimately boosting smart factory market revenues.

4. Top Smart Manufacturing Technologies in 2025

IoT is a network created when machinery and equipment are equipped to send and receive digital data. The Industrial Internet of Things (IIoT) lies at the heart of smart manufacturing as it encompasses not only connected assets but also the intelligent systems and automated processes in which they are integrated.

AI/Machine Learning plays a vital role in smart manufacturing with the ability to analyze big data, identify trends, forecast demand, and optimize decision-making.

Big Data acts as the “fuel” of smart manufacturing. By supplying AI systems with massive and diverse sets of complex production data, you provide the breadth necessary for systems to make increasingly accurate conclusions and learn faster over time.

Autonomous Robots: While not new, what's noteworthy is the ability of connected assets using smart technologies to automate operations. Smart factories rely on automation to achieve the agility and speed they require.

Additive Manufacturing/Hybrid Manufacturing: Better known as 3D printing, additive manufacturing enhances resilience and flexibility. For instance, a Boeing 747 jet comprises over six million parts - each needing replacement on different schedules. Rather than storing all those parts, intelligent metal or plastic 3D printers can access maintenance logs and produce parts on-demand, enabling companies to maintain a "virtual inventory."

5G Connectivity: With 5G, businesses harness the benefits of cloud internet connectivity and extend them with much lower latency, significantly faster speeds, and nearly limitless scalability.

These are just the top six advanced technologies applied in smart manufacturing. Beyond these, other cutting-edge technologies like edge computing, digital twins, and more are also emerging. A smart factory paired with intelligent production processes will undoubtedly deliver superior efficiency and value. Targeting a sustainable development future is the direction we believe every manufacturing enterprise will pursue in the new context.

5. Real-World Applications of Smart Manufacturing

Leading the Way in Automation and Robotics

Heidenhain is a leading example of revolutionizing the manufacturing industry. With extensive experience and outstanding developments in the application of technology in production, Heidenhain has launched intelligent and increasingly optimized products for partners and customers.

Heidenhain's focus on research and development has put them at the forefront of automation and robotics in the manufacturing industry. Their solutions enable manufacturers to automate their production processes and eliminate manual intervention, resulting in increased efficiency, worker safety and productivity. Some of the most notable products include motor drive systems, position feedback systems for robotic applications and dedicated software solutions for Industry 4.0.

Sunhouse Group: Adopting the 3S iFACTORY Smart Factory Model

Sunhouse Group has implemented a digital transformation strategy in manufacturing using the 3S iFACTORY smart factory model developed by ITG Technology. The first deployment was at the ALUBA plastic factory, which includes three workshops across 4,000 square meters, featuring 60 plastic injection molding systems with conveyor robots and 25 stamping units. This setup significantly enhances automation.

The adoption of 3S iFACTORY has enabled seamless information flow from the factory floor to executive management, ensuring better decision-making and productivity. The ALUBA factory now boasts a monthly production capacity of up to 3 million products.

Rạng Đông: A Pioneer in Industrial Digitalization in Vietnam

Rạng Đông Light Source and Vacuum Flask Joint Stock Company is a leading example of smart manufacturing adoption in Vietnam. The company has incorporated robotics, machine learning, artificial intelligence (AI), and the Industrial Internet of Things (IIoT) into its production lines.

These technologies have allowed Rạng Đông to enhance operational efficiency, product quality, and responsiveness to market demand—setting a benchmark for other Vietnamese manufacturers pursuing smart factory transformation.

>> See more: 5 Ways Heidenhain is Revolutionizing the Manufacturing Industry With Advanced Technologies and Sustainable Solutions

6. Conclusion

Smart manufacturing is no longer just a trend—it is becoming a strategic objective for many manufacturers worldwide. The journey to build and upgrade a factory toward smart production requires significant time, effort, and dedication. At AMS, we understand this challenge and are committed to our mission of delivering advanced technical solutions to support manufacturers along the way.

As the official distributor of globally recognized brands such as Heidenhain, Sandvik Coromant, GF, Hyperion, Norton, and more, AMS proudly serves as the trusted bridge between manufacturers and leading industrial technology providers.

We are honored to accompany your business in the journey toward smart, efficient, and sustainable manufacturing. Contact AMS today to turn your ideas into reality with our tailored engineering solutions.

Thank you for your trust and partnership!

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797