Methods of Plastic Mold Polishing: Manual vs. Modern Machinery

Both manual plastic mold polishing methods and machine-based polishing techniques are widely used in the industry. However, this article goes beyond a simple comparison of the two methods. AMS provides valuable insights not only for mold manufacturers and production engineers but also for those utilizing molds in their manufacturing processes. Discover the best methods of plastic mold polishing today!

1. Why Choosing the Right Methods of Plastic Mold Polishing Matters

Plastic molds are essential for producing high-precision plastic, metal, or glass products. To ensure that the final products meet quality standards, mold surfaces must be smooth and free from defects such as scratches, waves, or burrs.

Manufacturers must select the most suitable plastic mold polishing method based on the material being processed and the scale of their production facility. Whether you are a mold manufacturer or an end-product producer relying on molds in your production process, mold polishing plays a critical role in maintaining product quality, cost efficiency, and business reputation.

Key Benefits of Choosing the Right Plastic Mold Polishing Method:

-

Enhances product quality – Ensures a flawless, smooth, and glossy finish with minimal defects.

-

Extends mold lifespan – Reduces friction and wear during production.

-

Boosts production efficiency – Speeds up product release from molds, increasing overall productivity.

>> See more: What are the benefits of using polishing solutions for surface finishing?

2. Overview of Methods of Plastic Mold Polishing

There are two primary methods of plastic mold polishing: manual polishing and machine-based polishing. But which one is the better option? In reality, each method has its own advantages and limitations. The choice should not be based on preference but rather on the mold surface requirements to ensure the most effective polishing process.

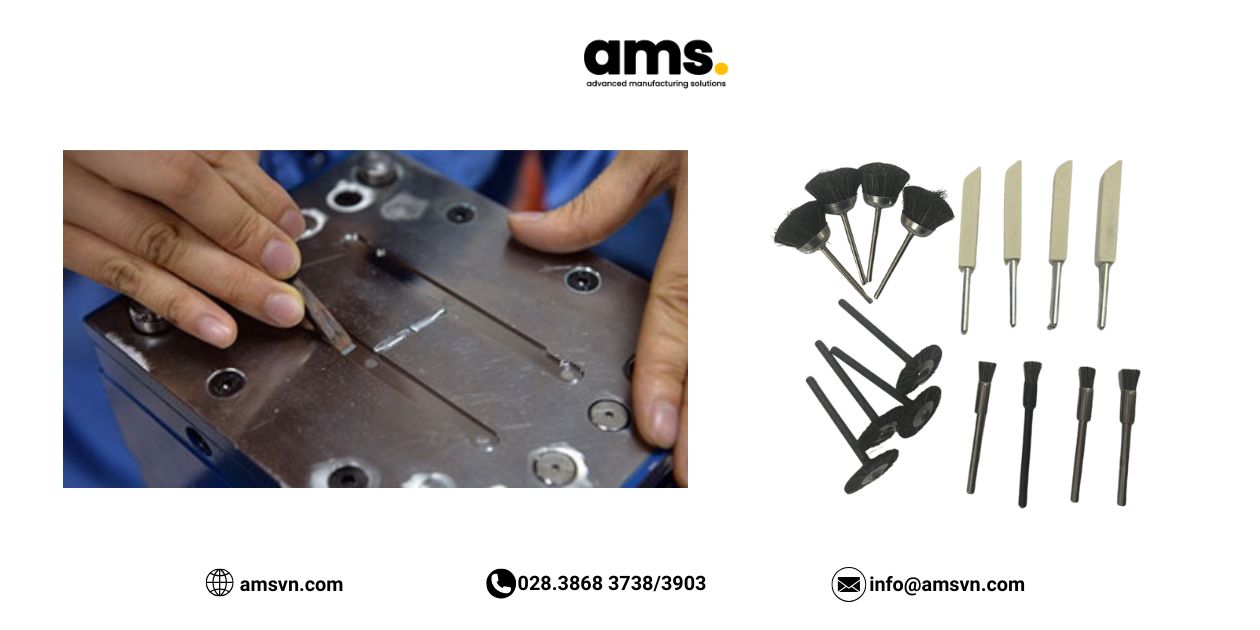

Manual polishing is a traditional method where technicians use handheld tools to refine the mold surface. This process involves materials such as sandpaper, grinding stones, diamond paste, and polishing compounds. It provides precise control, making it ideal for intricate details and hard-to-reach areas.

As technology advances, machine-assisted mold polishing has become increasingly popular, especially in large-scale manufacturing facilities. Various types of polishing machines are utilized, including: Vibratory polishing machines; Ultrasonic polishing machines; Electrochemical polishing machines; CNC grinding machines; Lapping machines.

Each method serves a specific purpose, and selecting the right plastic mold polishing method ensures optimal surface quality and production efficiency.

3. Manual Mold Polishing

3.1 Advantages

-

Control over surface smoothness: The polishing level can be adjusted as desired based on the applied force. Manual polishing allows a better feel of surface friction, making it easier to fine-tune the process.

-

Ideal for small, intricate mold details: Hard-to-reach areas such as deep grooves or narrow cavities often require the precision and dexterity of manual polishing.

-

Low investment cost: No need for expensive machinery; the cost mainly depends on the materials used and the technician’s skill level.

3.2 Limitations

-

Time-consuming and labor-intensive: This method requires patience and advanced skills, often taking hours or even days to complete a large mold.

-

Quality depends on the operator's expertise: Inexperienced workers may struggle to achieve a consistent surface finish.

-

Higher risk of errors: Since the process is performed manually, inconsistencies and defects are more likely to occur.

4. Mold Polishing with Modern Machinery

4.1 Advantages of Machine-Based Mold Polishing

-

Optimized time and increased productivity: Machines can operate continuously, accelerating the mold finishing process and improving production efficiency.

-

Superior precision: With automated parameter adjustments, polishing machines ensure uniform surface smoothness and gloss across the entire mold.

-

Minimized technical errors: Automation reduces human-related mistakes, enhancing the consistency and quality of the final product.

4.2 Limitations of Machine-Based Polishing

-

High initial investment: Polishing machines require significant capital, including equipment purchase, maintenance, and operational costs.

-

Limited access to intricate details: Despite their precision, machines struggle with complex designs or hard-to-reach areas, sometimes requiring manual assistance.

-

Requires skilled operation: To ensure optimal performance and prevent damage to the mold, operators must be properly trained in machine handling techniques.

5. Comparison Table: Manual vs. Machine-Based Mold Polishing

| Criteria | Manual Polishing | Machine-Based Polishing |

|---|---|---|

| Time Efficiency | Time-consuming, requires high patience and skill. | Fast and continuous operation, improving productivity. |

| Surface Smoothness Control | Allows manual adjustment for desired finish quality. | Ensures consistent smoothness with automated settings. |

| Suitability for Complex Details | Ideal for intricate and hard-to-reach areas. | Struggles with small, detailed, or hidden sections. |

| Error Rate | Higher risk of inconsistencies due to human factors. | Reduces human error, enhancing surface uniformity. |

| Initial Investment Cost | Low, as it relies on hand tools and operator skill. | High, requires expensive machinery and maintenance. |

| Operator Skill Requirement | Requires craftsmanship and experience. | Needs trained operators to handle and program machines. |

| Production Scalability | Limited scalability due to manual labor dependency. | Suitable for mass production with automated processes. |

6. Optimal Mold Solutions from AMS

According to Mordor Intelligence, a leading market research firm, Vietnam’s plastics market is estimated to reach 10.92 million tons in 2024 and is projected to grow to 16.36 million tons by 2029, expanding at a CAGR of 8.44% (2024-2029). To achieve superior production efficiency, Vietnamese manufacturers must prioritize both maintenance and optimization of machinery and equipment. Given this market potential, the mold polishing industry is set for growth, driven by increasing demand for mold maintenance in production.

With over two decades of experience in precision engineering, AMS deeply understands the industry's needs and key concerns, such as:

-

Product quality: Are the materials and polishing solutions up to standard?

-

Certification & documentation: Is everything transparent and compliant?

-

Cost-effectiveness & efficiency: Can polishing solutions truly optimize performance and expenses?

AMS plays a pivotal role in the mold polishing industry, providing technical services and superior polishing solutions. Choosing AMS means selecting:

-

Trusted, high-quality products at competitive prices, sourced from Kemet and Hyperion

-

Clear, transparent import procedures and quality certification

-

On-time delivery commitments to ensure manufacturers' production schedules

-

Diverse material options tailored to manufacturers' needs, reducing procurement time for purchasing teams

Contact AMS engineers today via hotline: 028 3686 3738 for free and detailed consultation!

>> Explore now: Polishing Solutions – Elevating Surface Quality in Manufacturing

7. Conclusion

Whether using traditional manual polishing or modern machine-based methods, manufacturers must choose the right polishing solution for each approach. AMS is committed to supporting customers by providing high-quality, reliable, and optimized polishing solutions. Contact AMS today for expert consultation on your polishing needs. Thank you, and we wish all manufacturers continued success and prosperity!

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797