How to increase the life of medical plastic injection molds?

Medical plastic injection molds hold an essential role in the production of medical tools, including IV tubing, test tube molds, PET test tubes, and more. Extending the lifespan of medical plastic injection molds is key to maintaining production quality and ensuring compliance with the rigorous standards required for medical devices. So, how can the lifespan of medical plastic injection molds be increased? The following article will be especially useful for mold manufacturers and medical device producers. Let’s explore the solutions together with AMS!

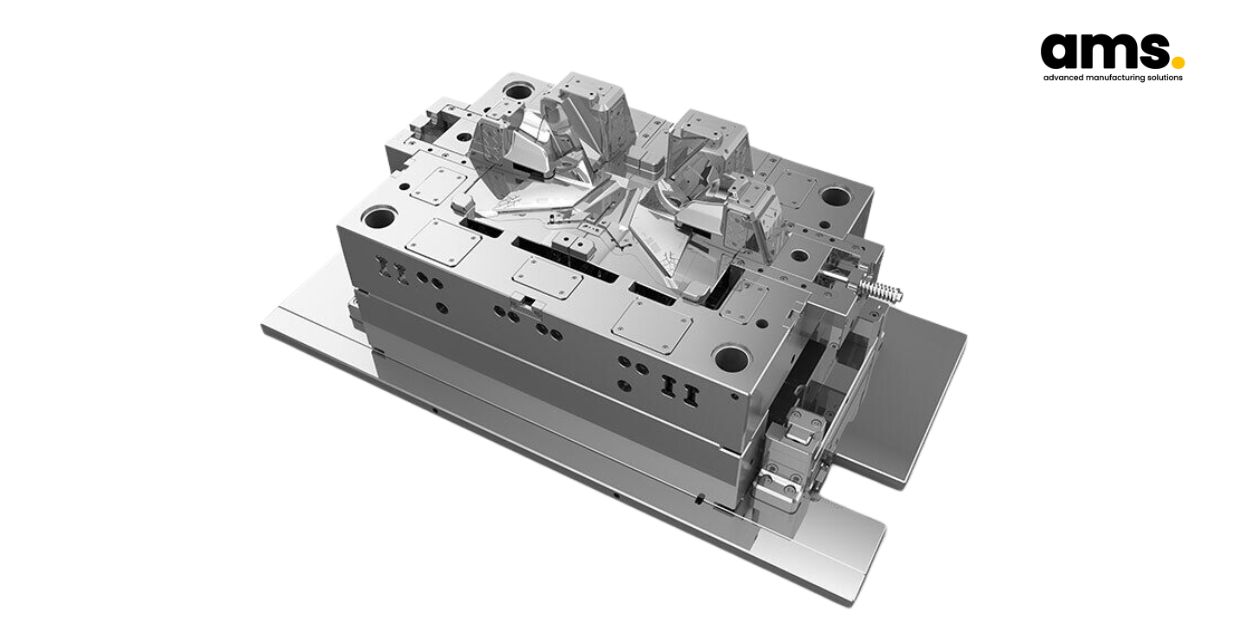

1. What Are Medical Plastic Injection Molds?

Medical plastic injection molds are designed to create essential and practical tools and equipment used in various medical fields. At their core, these molds operate using the plastic injection molding method, utilizing durable, reliable materials that meet healthcare standards, including FDA (U.S. Food and Drug Administration) regulations.

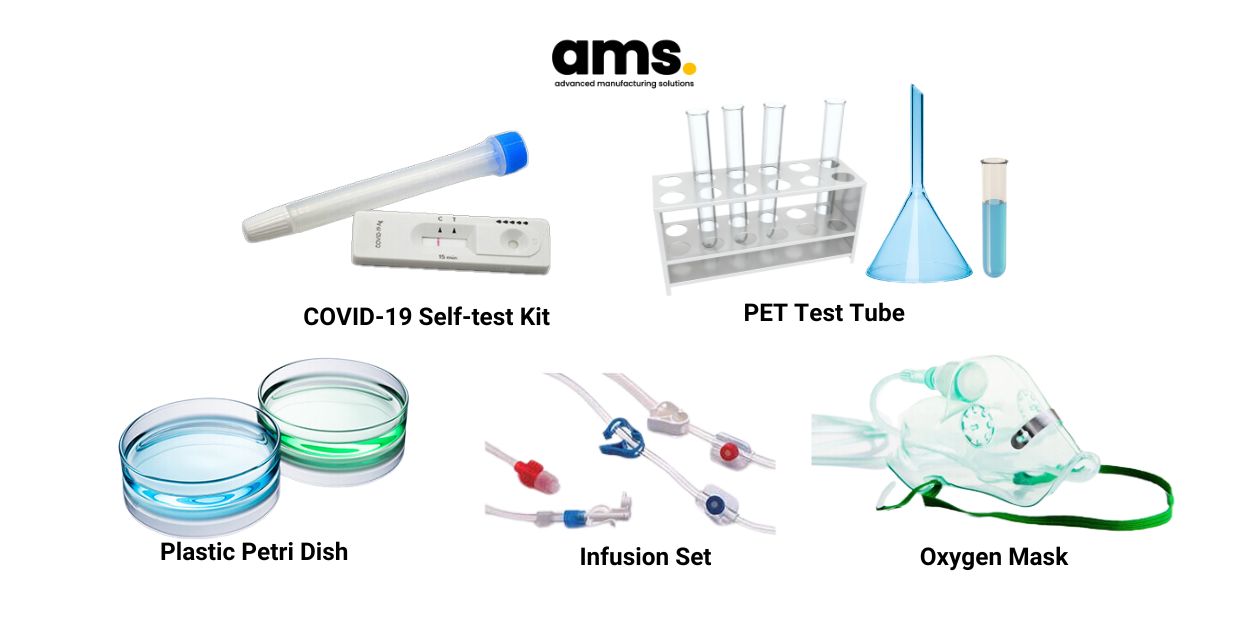

Using medical plastic injection molds offers cost efficiency for large-scale production, ensuring high consistency and tight tolerances. For example, FDA-compliant COVID-19 test kits, widely circulated during the pandemic, are produced through plastic injection molding using molds specifically designed for such kits.

2. Application and some materials for manufacturing medical instruments when using plastic injection molds

2.1. Applications of Medical Plastic Injection Molds

Each type of medical plastic injection mold is designed to produce specific medical tools and equipment. Some common applications include:

-

Dental instruments

-

Surgical tools

-

Medical devices: syringes, oxygen masks, medical suction tube tips, petri dishes, etc.

-

Prosthetic devices: artificial limbs and models for experimental purposes.

-

Surgical blades

-

Medical device casings and other components

2.2. What are the materials used in plastic injection to create medical tools?

The choice of injection molding materials significantly impacts the lifespan of molds. Additionally, materials used to produce medical devices must possess unique advantages and properties, such as high molecular weight, chemical resistance, and heat tolerance. Therefore, careful evaluation of materials is essential for the production process, as medical molds are tailored for a variety of tools.

Common Materials for Medical Device Production

-

Polycarbonate (PC): Polycarbonate is a transparent material commonly used in medical tubing. It offers high tensile strength, shear strength, and flexural strength. It is heat-resistant, absorbs minimal moisture, and is more durable than acrylic.

-

PEEK (Polyether Ether Ketone): PEEK is a premium medical-grade plastic known for its excellent chemical resistance and high tolerance to cracking and fatigue. It can be sterilized using autoclaves and is FDA-approved for food contact. Additionally, it meets UL 94 V-0 flame-retardant standards.

-

Ultem: Ultem is widely used in medical devices and is autoclave-sterilizable. It withstands environmental stress, resists cracking, and exhibits exceptional dimensional stability, strength, and rigidity.

3. Why is medical mold maintenance important?

As previously mentioned, medical tools such as syringes, medical device casings, and test tubes are often produced in large batches to optimize costs. Consequently, medical plastic injection molds operate at maximum capacity during each production cycle. These medical products demand high precision, smooth surfaces, and zero defects.

If medical injection molds are not properly maintained, they may suffer from wear, rust, and surface defects, leading to the following consequences:

-

Reduced product quality

-

Increased machine downtime

-

Higher repair or replacement costs

Proper maintenance not only ensures efficient mold performance but also helps businesses save on long-term costs. One critical aspect of mold maintenance is **polishing**, which offers the following benefits:

-

Removes plastic residue and debris without damaging the mold surface.

-

Restores surface smoothness, ensuring high-quality medical plastic products.

-

Protects molds from wear and rust, extending their lifespan.

>> See more: What are the benefits of using polishing solutions for surface finishing?

4. Periodic Maintenance Process for Medical Plastic Injection Molds

Periodic maintenance is key to extending the lifespan of medical injection molds. Below is a basic maintenance process:

-

Clean the Mold After Each Production Cycle: Remove any residual plastic or dirt from the mold. Use specialized cleaning solutions to avoid damaging the mold surface.

-

Inspect and Polish the Mold: Regularly inspect parts such as cores, vents and pressure-bearing surfaces. Replace any worn-out components to prevent product quality issues. Polish the mold if surface defects appear; diamond polishing powder can be used to enhance the shine. It’s essential to apply moderate pressure to avoid damaging the mold’s surface.

-

Lubricate Moving Parts: Periodically lubricate moving parts, such as ejector pins or bearings, to reduce friction and prevent jamming.

Today, advanced technologies are also used to improve mold longevity:

-

PVD Coating (Physical Vapor Deposition): This technique creates a thin coating, enhancing the mold’s wear resistance.

-

CNC Grinding Machines: These automated machines perform precise grinding and polishing, improving accuracy and reducing maintenance time.

5. Choose a suitable polishing material supplier

AMS understands that mold manufacturers and medical device producers are always in search of polishing products that meet strict safety, reliability, and quality standards. AMS is confident in our ability to distribute products that ensure complete customer satisfaction and peace of mind:

-

High-Quality Grinding Stones: Compliant with industry standards.

-

Diamond Polishing Powder: Guarantees smoothness and safety for medical products.

-

FDA-Approved Polishing Solutions: Safe and effective for maintaining medical plastic injection molds.

At AMS, our team of skilled experts is always ready to listen and provide optimal surface treatment solutions for your molds. We are committed to quality because our customers' success is our success.

Discover our high-quality polishing products today. Increase efficiency and reduce maintenance costs – AMS is always here to support you!

6. Conclusion

Extending the life of medical plastic injection molds not only helps reduce maintenance costs but also improves production efficiency and ensures product quality. Using polishing products such as grinding stones, diamond polishing powder, and specialized solutions is an essential solution to maintain molds in optimal condition. Thank you for your interest in AMS's articles and products, we are honored to provide sustainable values and accompany your unit on the journey to improve production efficiency!

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797