How Measurement Accuracy Drives Sustainable Manufacturing Efficiency

Over the past two decades, sustainability has become a global priority. Economic growth is no longer viewed in isolation; it must go hand in hand with environmental protection. Sustainable manufacturing is now a defining trend worldwide, driving increasing demand for engineering solutions that support a green value chain.

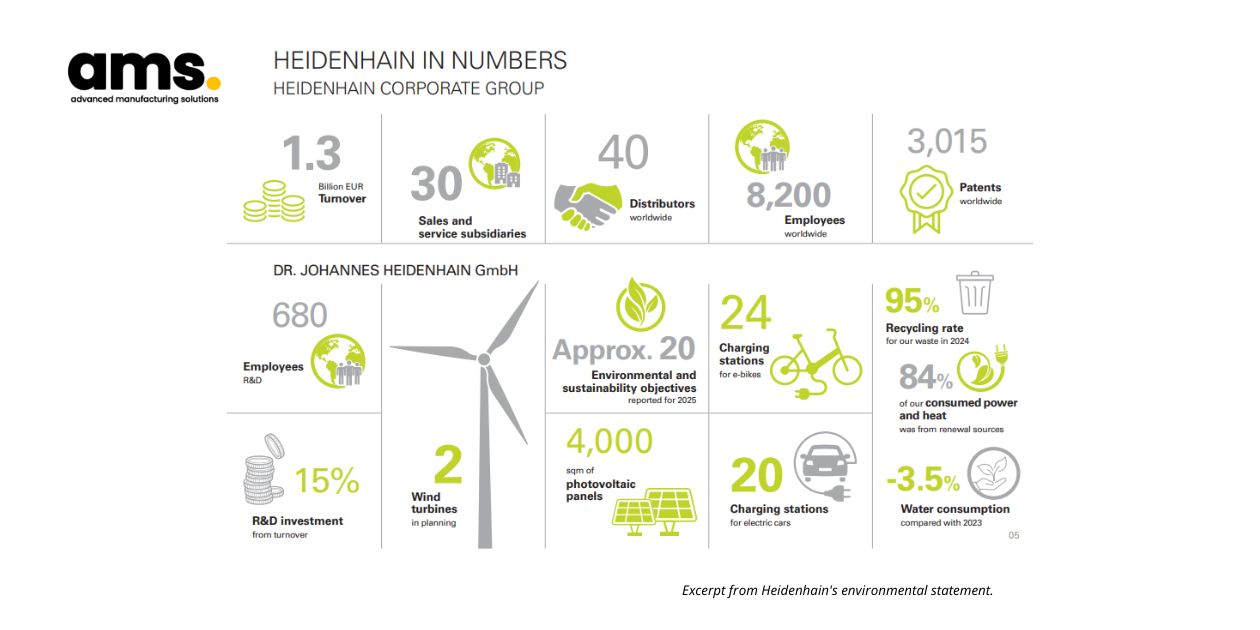

As the exclusive Heidenhain distributor in Vietnam, AMS is proud to share Heidenhain's environmental commitment, particularly its efforts in ecological balance and renewable energy adoption. Our goal is to help Vietnamese manufacturers access advanced engineering solutions that are internationally recognized as sustainably produced products, contributing directly to long-term manufacturing sustainability.

1. What Is Sustainable Manufacturing in the Manufacturing Industry?

1.1. From an Environmental Perspective

According to UN Sustainable Development Goal 12 (SDG 12) and international standards such as ISO 14001, sustainable manufacturing is defined as organizing production processes to meet current societal needs without compromising the ability of future generations to meet theirs.

This concept emphasizes a balance between three core pillars:

-

Economic growth

-

Social responsibility

-

Environmental protection

The objective is long-term, resilient development that aligns industrial expansion with natural resource conservation. As natural resources become increasingly scarce and climate change intensifies, sustainable manufacturing focuses on:

-

Optimizing raw material usage

-

Reducing waste and greenhouse gas emissions

-

Protecting worker rights and welfare

Rather than viewing production as a closed loop from raw materials to finished goods, this model extends to the entire product lifecycle, including recovery, recycling, and reuse.

Manufacturing remains a cornerstone of national economies. Today, however, competitiveness in manufacturing is closely tied to sustainability meeting stricter market requirements while complying with environmental regulations.

In Vietnam, government policies are pushing manufacturers to minimize environmental impact. Sustainability now starts at the equipment selection stage, where machines themselves are expected to be durable, efficient, and environmentally responsible.

1.2. From a Technical Perspective

In practice, before achieving environmental targets, manufacturers often begin by addressing technical issues that indirectly affect sustainability. Common concerns include:

-

Production interruptions caused by equipment failures

-

Scrap rates, dimensional errors, and excessive energy consumption

For example, CNC machines play a critical role in precision manufacturing. In some cases, inaccurate speed feedback on the control display does not originate from the entire machine, but from an unstable encoder component. This seemingly small issue can disrupt production schedules and reduce overall equipment efficiency.

From a technical standpoint, equipment that supports sustainable manufacturing must offer:

-

Longer service life

-

Stable and accurate operation

-

Reduced long-term operating and supply chain risks

These characteristics align closely with sustainability principles by lowering total cost of ownership and minimizing unnecessary resource consumption.

>> See More: Sustainable Manufacturing and Industrial Encoder Selection for Modern Factories

2. How Does Measurement Accuracy Stabilize Manufacturing Processes?

At AMS, we believe process stability is the foundation of long-term manufacturing value. Our mission is to connect manufacturers with precision measurement solutions that ensure consistent and reliable operations.

A stable process directly leads to:

-

Reduced dimensional errors

-

Lower scrap rates

-

Less rework and downtime

The solutions we promote in Vietnam are based on Heidenhain's measurement and control technology ecosystem, widely recognized for precision and reliability.

Accurate measurement systems help reduce resource consumption by enabling:

-

Precise position and motion control

-

Improved repeatability

-

Reduced machine downtime and re-machining

These benefits translate directly into higher productivity and more sustainable manufacturing outcomes.

3. How Measurement Technology Supports Sustainability Strategies

Heidenhain products are engineered to enhance machine performance and efficiency while actively supporting environmentally responsible manufacturing. This is why Heidenhain components are not considered consumables; they are designed to last for the entire lifecycle of the machine.

In addition, Heidenhain prioritizes:

-

Repairability and long-term maintenance strategies

-

The use of recyclable materials to ensure high recycling rates at end-of-life

3.1. How Heidenhain Encoders Contribute to Sustainability

The latest LC and RCN encoder generations for machine tools are a strong example. These encoders use true image scanning technology, which completely eliminates optical distortions caused by condensation or liquid contaminants.

As a result, compressed air systems are no longer required leading to a carbon footprint reduction of up to 99% over the encoder's operational lifetime.

3.2. How Heidenhain Controls Enhance Sustainability

With over 35 years of proven application experience, HEIDENHAIN controls are widely used in milling machines, lathes, drilling machines, and machining centers.

Beyond advanced axis motion control, their high-performance functions deliver:

-

Higher machining accuracy

-

Faster material removal rates

-

Greater process reliability

By minimizing non-productive time and improving overall machining efficiency, these control systems enable higher output with lower carbon emissions per finished part, a key factor in sustainable manufacturing.

4. Lessons for Vietnamese Manufacturers

For more than two decades, AMS has accompanied Vietnam's mechanical engineering industry through its transformation from early-stage equipment sourcing to global-standard manufacturing integration.

Our role extends beyond product distribution. AMS serves as a technical bridge, providing not only suitable engineering solutions but also reliable industry insights and technical knowledge during this period of rapid industrial evolution.

Below are several sustainability practices implemented by Heidenhain that we hope Vietnamese manufacturers can continue to learn from and adopt:

-

Transitioning energy supply to renewable sources such as wind and hydropower. Heidenhain currently meets 100% of its electricity demand using verifiable renewable energy

-

Improving energy efficiency by switching to LED lighting and optimizing compressed air systems

-

Expanding energy monitoring capabilities while continuously reducing waste and emissions

>> You might be interested: Why a Certified Mechanical Components Supplier Is the Foundation of Precision Manufacturing

5. Conclusion

The manufacturing industry is undergoing a major transformation driven by technological innovation and the global shift toward sustainable manufacturing. To remain competitive, manufacturers must stay aligned with emerging trends and continuously enhance their technical capabilities.

As an authorized distributor of leading precision measurement and control solutions, AMS is committed to supporting manufacturers on their sustainability journey. Contact us today to explore how accurate measurement technology can help you achieve long-term, sustainable production efficiency.

AMS Company, Ltd.243/9/10D To Hien Thanh str, Hoa Hung Ward, HCMC, Vietnam

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797