Top 5 Industries That Should Use Diamond Polishing Powder

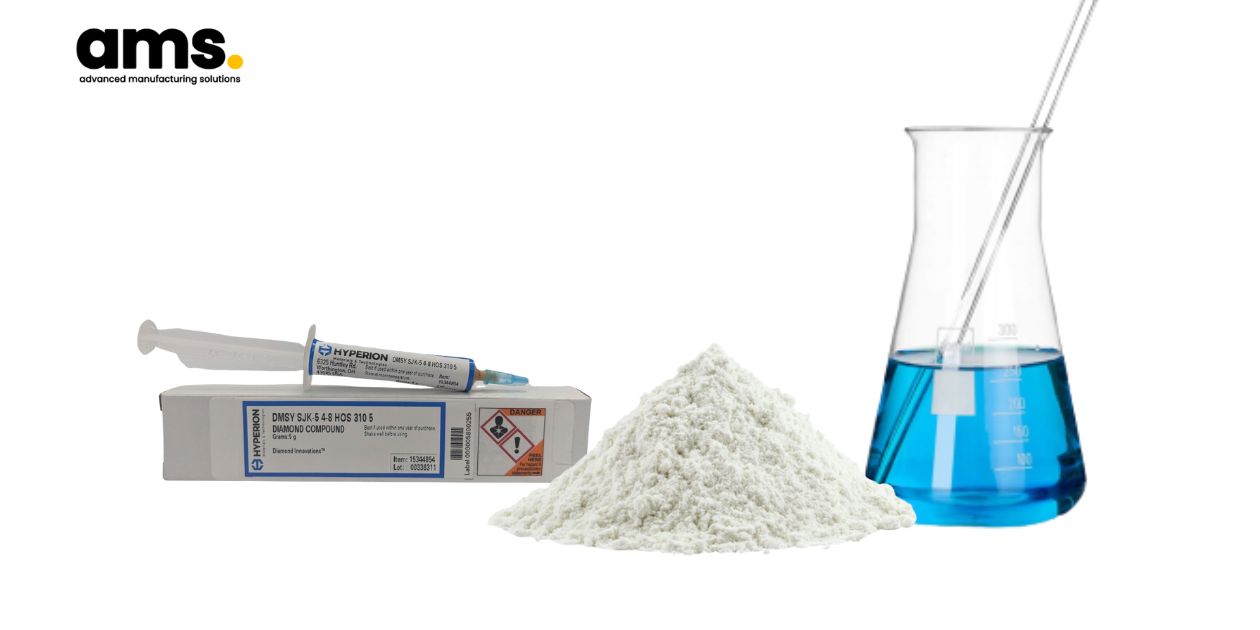

Diamond polishing powder from Hyperion, officially distributed by AMS in the Vietnamese market, is increasingly recognized as an optimal solution for both performance and cost-effectiveness in grinding and polishing applications. Are you looking for high-quality diamond powder with a price point tailored to the Asian market? Still comparing various types of diamond polishing powders to meet your production requirements? Don't miss the in-depth insights below!

1. What Is Hyperion Diamond Polishing Powder?

Diamond powder comes in a variety of types and particle sizes such as polycrystalline or monocrystalline diamonds. At AMS, we focus on distributing micron diamond powder manufactured by Hyperion. These powders have ultra-fine and consistent particle sizes (typically ranging from 0.25 to 50 microns), which enhance surface contact and create more cutting points for efficient material removal.

Different particle sizes serve different functions. Finer diamond powders are ideal for grinding and polishing, while coarser particles are used for more aggressive material removal. The diamond polishing powder from Hyperion includes both raw diamond powder and formulated diamond compounds, suitable for various industrial polishing and grinding applications.

2. Key Features & Applications

More than 60 years ago, Hyperion pioneered synthetic diamond technology, a legacy that continues through constant innovation. Today, Hyperion develops a wide range of diamond products including powders, slurries, compounds, and suspensions, all tailored to meet specific industrial needs. Let's explore several key industries where diamond polishing powder plays a crucial role:

>> See more: Advanced polishing solutions distributed by AMS

2.1. Diamond powders

| DIAMOND POWDER GRADE | Descriptions | SUGGESTED APPLICATION | INDUSTRY |

|---|---|---|---|

| SJK-5 | Monocrystal diamond powder - used in slurries and suspensions | Lapping |

|

| RJK-1 | Multi-crystal diamond powder - more friable than a monocrystal | Lapping/Polishing | |

| POLY | Polycrystalline diamond powder - available in sizes < 10 microns (µm) | Polishing | |

| NATURAL | Natural diamond powder - available in a variety of sizes | Gem Polishing |

2.2. Compound formulations

| COMPOUND IDENTIFICATION | COMPOUND FORMULATIONS (SOLUBILITIES) | RECOMMENDED USES | |

|---|---|---|---|

| K700 | Water soluble | For use where exceptional cleaning is required and where petroleum contamination is prohibited. Specimen prep applications command this product. | Used in specimen preparation and cross section analysis |

| K210 | Oil soluble | Recommended for controlled lapping of carbide drawing dies, cold heading dies, and other polishing applications | Primarily used in mold and die polishing |

| G400 | Water/Oil soluble | Complements the use of oil as well as water for achieving more productive results and facilitating cleaning. | Used where corrosion must be minimized but where oil cannot be tolerated. |

2.3. Slurry and Suspension

| SLURRY/SUSPENSION IDENTIFICATION | SLURRY/SUSPENSION FORMULATIONS | Slurry | Suspension | |

|---|---|---|---|---|

| K400 | Oil-Based | Straight oil with petroleum base and additives | X | |

| K285T | Water-Based | Straight water, for use where exceptional cleaning is required and where petroleum contamination is prohibited | X | |

| K450, K1500 | Water-/Oil-Based | Compliments the use of oil as well as water for achieving more productive results | X | X |

| LDP | Water-/Oil-Based | Diamond is dispersed in ultra-pure deionized water to eliminate agglomerates that can occur in submicron powders | X | X |

3. Top 5 Industries That Should Use Diamond Polishing Powder

3.1. Automotive Industry

The automotive manufacturing industry especially the production of components has seen rapid growth in recent years. Every part of a finished vehicle must meet stringent standards for appearance, surface accuracy, and high-precision machining.

Diamond polishing powder is a superior choice for manufacturers of engine parts, electrical systems, suspension and brake components, body and chassis elements, plastic parts, and lighting systems. It ensures smooth, defect-free surfaces and contributes to the performance and aesthetics of the final product.

3.2. Electronics Industry

In electronics manufacturing, polishing is a crucial step to achieve flawless finishes. For example, the back panels of smartphones and the edges of glass screens must be meticulously polished to remove micro-scratches and ensure visual and tactile quality. Likewise, metal frames and casings are polished to prepare for processes like zinc plating, anodizing, or electroplating.

Hyperion diamond polishing powder is the ideal solution for electronics manufacturers seeking precision and consistent surface quality.

3.3. Home Appliance Manufacturing

Manufacturers of kitchenware, cutlery, sinks, and other home appliances require extremely smooth and polished surfaces. These products often demand a mirror-like finish, where even the slightest scratch is unacceptable.

Hyperion's diamond polishing powder helps deliver a flawless surface finish, enhancing both the visual appeal and functional quality of consumer household products.

3.4. Jewelry Industry

When it comes to gold, silver, and platinum jewelry, a perfect, shiny finish transforms items into luxurious pieces.

Hyperion diamond polishing powder meets the highest quality standards required in the jewelry and gemstone industry, ensuring brilliant surfaces with maximum luster and refinement.

3.5. Oil & Gas Industry

In the oil and gas sector, precision components such as mechanical seals and parts used in equipment maintenance (e.g., valves and sealing systems) require advanced polishing solutions.

Hyperion diamond polishing powder offers a high-performance, reliable solution for these demanding applications, improving durability and equipment performance.

>> See more: What Is the Optimal Solution for Semiconductor Wafer Polishing?

4. Some Tips for Troubleshooting When Polishing with Diamond Powder

It's important to identify the root cause of a problem in order to make timely adjustments. Below are some common issues that machinists often encounter during the polishing process:

-

Scratches: Caused by contaminated tools or work areas, and/or the workpiece not being properly cleaned after using the abrasive (grit) from the previous stage.

-

Wavy Surface: Caused by switching between grit levels that are too far apart, or by uneven pressure applied during polishing.

-

Pitting on the Surface: Caused by slag or impurities in the steel, or excessive polishing pressure.

-

Orange Peel Effect: Caused by polishing with a machine for too long, leading to overheating in a small area; or by insufficient pressure when polishing soft steel.

5. Conclusion

Diamond polishing powder plays a vital role across various industries, contributing to enhanced surface quality and precision. AMS is proud to be the official distributor of Hyperion in Vietnam, bringing advanced polishing solutions to manufacturers nationwide. Contact AMS today for a free consultation and discover the right diamond polishing solution tailored to your industry needs.

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797