The Importance of Automotive Mould Polishing in Modern Manufacturing

The demand for automotive mould polishing will continue to rise and expand in the future, driven by the growth of the automotive manufacturing industry. According to the Ministry of Industry and Trade, the motor vehicle production index increased by 10.8% in the first eight months of 2024 compared to the same period in 2023 (higher than the 6.4% growth rate recorded in the first seven months of 2024). This article will address common questions about the polishing process and provide the most suitable polishing solutions for your business.

1. What Are Automotive Moulds?

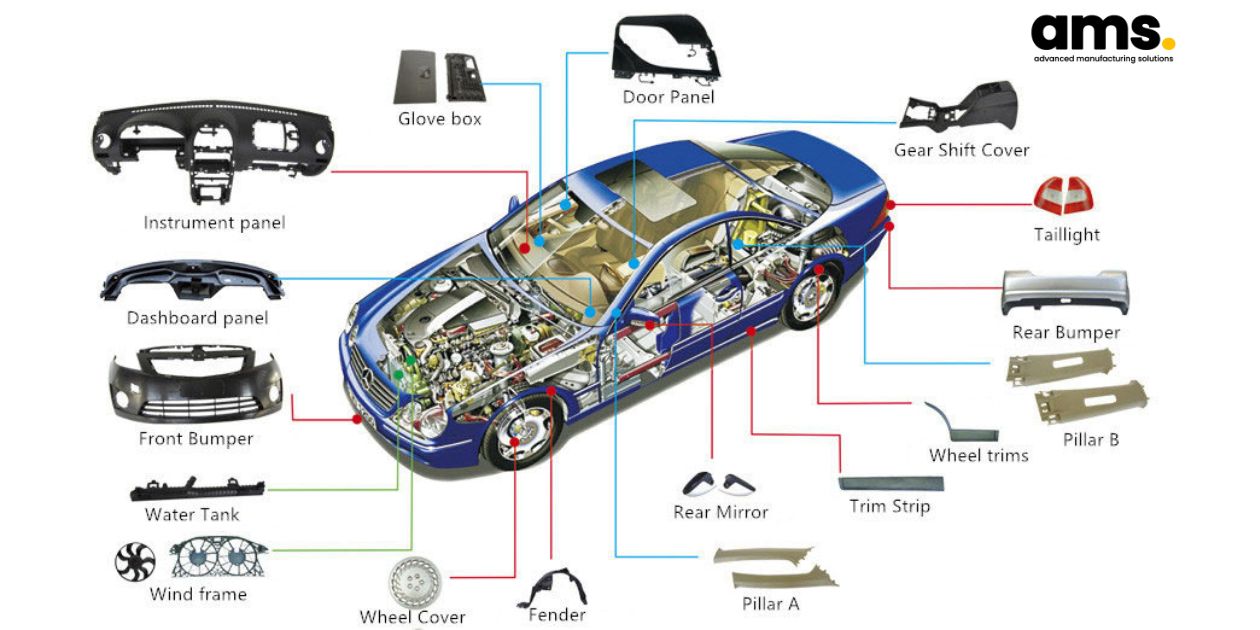

Automotive moulds (also referred to as car moulds or automotive plastic moulds) are used to create various parts and components of automobiles, such as car bodies, engine parts, details, and interiors. These are typically manufactured using the injection molding process, a widely applied method in the automotive parts industry.

Each plastic part or detail of a car requires different moulds to produce components that serve distinct roles and positions within the vehicle. Some common types and applications of automotive moulds include:

-

Interior trim moulds

-

Bumper moulds

-

Dashboard moulds

-

INS IMD moulds

-

Battery box moulds

-

Seat moulds

2. The Growing Demand for Automotive Mould Polishing

According to Mordor Intelligence, a leading market research company, the automotive die casting market was valued at USD 61.05 billion in 2021 and is projected to reach USD 87.54 billion by 2027, growing at a CAGR of over 6.19% during the forecast period (2022-2027).

The Asia-Pacific region is expected to play a critical role in this growth trend. Automakers are increasingly focusing on meeting targets for durable, lightweight, and cost-efficient automotive components, which has led to advancements in mould production technologies.

In Vietnam, data from VAMA, TC Group, and VinFast shows that the total automotive sales exceeded 510,000 units in 2022, setting a new record. Riding on this growth, the government is steering towards localization strategies, encouraging businesses to participate in the automotive parts supply chain.

Automotive mould polishing holds a pivotal role in the value chain of car production. The bright prospects of Vietnam's automotive industry are paving the way for new breakthroughs, especially in supporting industries such as mould polishing.

3. Why Is Automotive Mould Polishing Necessary?

Similar to other manufacturing sectors, all moulds must be polished precisely to meet production requirements. The ultimate goal of automotive mould polishing is to ensure smooth surfaces, eliminate defects, and extend the lifespan of the mould.

Although the polishing process is fundamentally the same across industries, automotive moulds require attention to specific details:

-

Polishing Time: Automotive moulds are often large with wide surfaces, requiring more time and careful polishing.

-

Precision: Automotive mould surfaces demand perfection to ensure aesthetic quality, particularly for critical components such as car bodies, exteriors, and headlights.

-

Specialized Tools and Materials: Automotive moulds are typically made from high-strength steel, necessitating the use of specialized polishing tools and materials.

4. General Polishing Steps for Automotive Moulds

Preparation: Clean and inspect the mould for defects.

-

Choose the Right Tools

-

Grinding stones, diamond powder.

Specialized polishing solutions.

-

Divide the process into stages: rough grinding, fine grinding, and finishing.

-

Use automated or semi-automated equipment.

Quality Inspection: Check gloss levels, dimensions, and accuracy.

>> See more: Key Considerations in the Plastic Injection Mold Polishing Process

5. AMS - Your Trusted Provider of High-Quality Mould Polishing Materials

At AMS, we offer materials and tools tailored to your polishing needs. As a reputable distributor working closely with leading partners like Hyperion and Kemet, we guarantee 100% satisfaction in meeting your automotive mould polishing requirements.

With a team of seasoned experts, we deeply understand your industry and provide invaluable advice. Here are some product suggestions from us:

Hyperion offers superhard materials:

-

Diamond powders for polishing high-strength alloy steel moulds.

-

Grinding wheels ideal for large moulds like car bodies and bumpers.

-

Diamond files for polishing small details and hard-to-reach areas of automotive moulds.

Kemet specializes in:

-

Diamond pastes and polishing compounds for final surface finishing.

-

Automatic mould polishing machines.

-

Polishing fluids.

-

Grinding discs, polishing pads, and manual lapping tools.

AMS is the optimal choice for quality, efficiency, and cost-effectiveness. Our internationally acclaimed quality speaks for itself, and the choice is yours. Contact us today for detailed consultation tailored to your needs.

6. Conclusion

Automotive mould polishing demands precision, meticulousness, and the use of specialized tools and materials. Let AMS be your partner in manufacturing excellence. Thank you for reading this article, and we wish your business continued success and prosperity!

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797