Vietnam's Mold Market: Opportunities and Challenges

Vietnam's mold market has undergone significant transformations in recent years, as mold manufacturing is considered the backbone of the production industry. Rapidly growing sectors such as automotive, home appliances, and electronic components are setting increasingly stringent standards for mold manufacturing. Join AMS as we explore an in-depth overview of the market and the solutions we provide to support mold manufacturers in Vietnam.

1. Overview of Vietnam's Mold Market

A 2024-2029 technology and market analysis report by Research and Markets states: "The global plastic injection molding market was valued at $191 billion in 2023. It is expected to grow from $192.7 billion in 2024 to $235.7 billion by the end of 2029, with a compound annual growth rate (CAGR) of 4.1% from 2024 to 2029. The global plastic injection molding industry has become an essential factor in modern manufacturing and finds widespread applications across various industries….”

Following this trend, Vietnam, as a developing country, is striving to establish its presence in high-growth industries. Mold engineering plays a crucial role in supporting the expansion of industries such as household plastics, electronics, automotive, and motorcycles. According to the Ministry of Industry and Trade, Vietnam's mold and precision engineering industry is currently valued at over $1 billion per year, with an annual growth rate of 18%, attracting significant interest from both domestic and international enterprises.

However, Vietnamese companies only produce 8.5% of injection molds, while the rest are stamping molds. In terms of capabilities, domestic manufacturers have reached technology levels 3 and 4 in a five-tier classification system, while levels 1 and 2 still rely on imports from global corporations.

Industry experts and key mold manufacturing enterprises indicate that Vietnam's mold production technology and equipment currently reach 50-70% of global standards, comparable to countries such as the Philippines and Indonesia. However, the ability to master and fully utilize available technology remains a challenge, preventing businesses from fully leveraging their advanced equipment.

>> See more: Overview of Vietnam's precision engineering market

2. Vietnam's Competitive Advantages in Mold Manufacturing

The demand for molds in industries such as plastics, mechanical engineering, machinery components, and electronics is rapidly increasing. This demand not only drives higher product quality but also enhances the capabilities of domestic enterprises, allowing them to integrate more effectively into the global supply chain. From a fragmented network of small-scale workshops, Vietnam has evolved into an attractive destination for global manufacturers thanks to its competitive costs, abundant workforce, and improving technical expertise.

To increase localization rates in mold manufacturing and other key industrial sectors, the Vietnamese government has introduced several*support policies, collectively referred to as the Government Support Program." These include tax reductions, financial assistance, and vocational training programs aimed at upskilling the workforce. Such initiatives are crucial for ensuring the sustainable growth of Vietnam's mold industry.

3. Challenges Facing Vietnam's Mold Industry

Despite its potential and promising growth outlook, Vietnam's mold industry faces several key challenges related to skilled workforce availability, technological capabilities, and market competition.

3.1 Shortage of High-Quality Workforce

A survey conducted by Samsung Vietnam and the Ministry of Industry and Trade revealed concerning statistics about the skill level of mold industry professionals: 50% of the 120 surveyed experts were classified as entry-level. 39% were rated at an intermediate level. Only 11% were considered experts, and none reached the professional level. This shortage of both quantity and quality in the workforce highlights a significant gap in Vietnam's mold industry, which struggles to develop and retain skilled specialists.

3.2 Increasing Market Competition

Vietnam's mold industry faces strong competition from international players, particularly Taiwan. In 2002, Taiwan exported 48,726 tons of molds to markets including China, the U.S., Indonesia, Thailand, and Vietnam, with a total value of 18.3 billion New Taiwan dollars. Taiwanese molds meet international quality standards while costing only 50% of imported molds, thanks to continuous adoption of new materials, automation, and IT-driven production processes.

With rising raw material costs and a cost-conscious market, Vietnamese manufacturers must navigate an increasingly competitive landscape where price and efficiency are critical factors.

3.3 Challenges in Meeting High-Tech Manufacturing Requirements

Due to limitations in design and manufacturing capabilities, domestic companies can only produce molds for basic mechanical components and some parts for foreign joint ventures. However, for high-precision products such as washing machines, refrigerators, air conditioners, cars, and motorcycles, Vietnamese manufacturers still rely on semi-finished imports or foreign-made molds.

Additionally, most mold manufacturers operate with outdated technology. Even companies that have invested in advanced equipment often face redundant investments due to a lack of collaboration within the industry. Furthermore, the talent pool for mold design, manufacturing, and technology transfer is fragmented, further hindering the sector's development.

4. Outlook for Vietnam's Mold Industry

According to Mr. Cao Tiến Trung - Deputy Director of HTMP Co., Ltd., “In Vietnam's supporting industry in general and Vietnam's mold industry in particular, for more than 10 years now, quite a number of Vietnamese enterprises have participated in this field. However, until now, our industry is still in its early stages, and the preparation as well as the potential for future development remain significant.”

According to the Ministry of Industry and Trade, in the coming time, promoting cooperation in workforce training and improvement consulting will continue to be one of the Ministry's key focuses, contributing to enhancing the capabilities of small and medium-sized enterprises to meet the requirements of both domestic and international customers.

At the same time, the Ministry of Industry and Trade will continue to refine policies to promote the development of the supporting industry in general and the mold sector in particular; introduce programs, preferential mechanisms, and incentives to encourage businesses to apply modern science and technology in mold manufacturing to create a solid foundation for domestic industries and exports.

5. The Role and Contribution of Technical Solutions to the Development of Vietnam's Mold Market

Vietnam's mold industry is experiencing strong growth, serving key sectors such as automotive, electronics, medical, and consumer goods. However, to enhance production capacity and compete with international markets, enterprises in the industry must not only invest in modern machinery but also adopt advanced technical solutions.

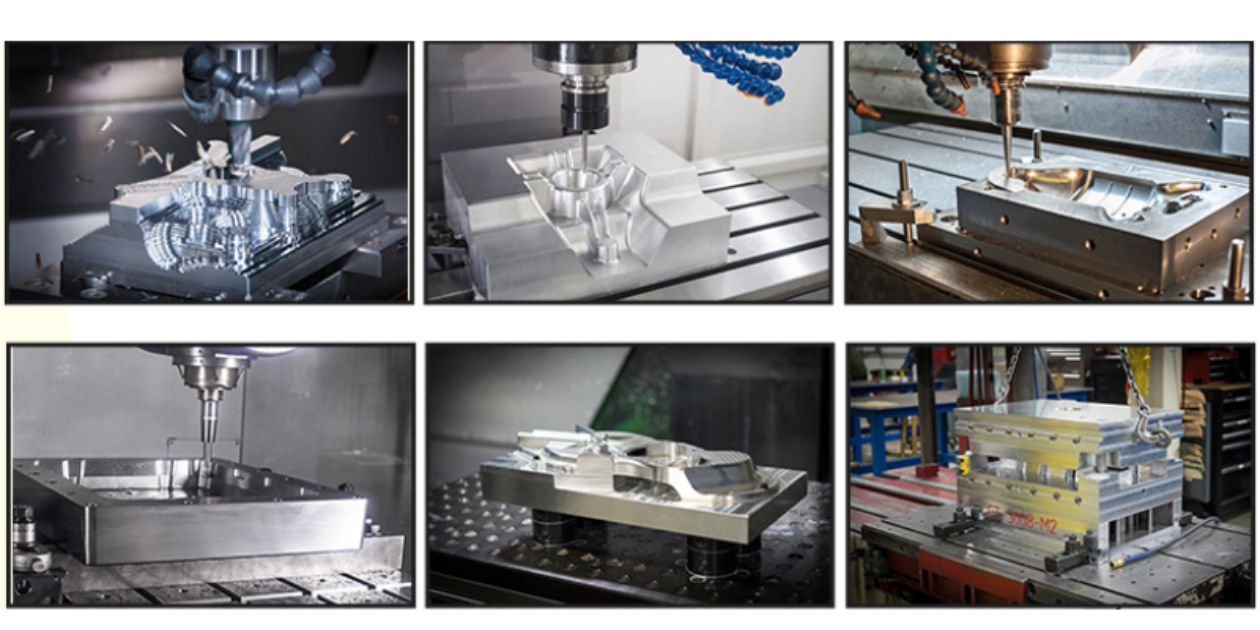

5.1 Technical Solutions - The Key Factor in Mold Quality

In mold manufacturing, precision and surface quality are top priorities. Mold polishing solutions, precision machining, and advanced measurement technologies ensure that molds meet high standards, minimize production defects, and extend mold lifespan. Additionally, using high-quality cutting tools enhances machining efficiency and optimizes production costs.

Moreover, the trend of automation and digitalization in the mold industry is creating new opportunities. Precision measurement solutions using sensors, data analysis software, and machining process monitoring systems help businesses optimize production processes, increase productivity, and maintain stricter quality control.

>> See more: AMS's products

5.2 AMS - A Comprehensive Solution Provider for the Mold Industry

As a provider of precision engineering solutions, AMS plays a crucial role in supporting Vietnam's mold manufacturers in improving production capabilities. We not only supply high-quality products from leading brands such as Norton, Kemet, Hyperion, Sandvik Coromant, and Heidenhain but also offer in-depth technical consulting services, helping businesses select and apply the right tools and materials for each production stage.

AMS's products and solutions optimize mold machining processes, improve precision, shorten production time, and ensure product quality. As a result, Vietnamese mold manufacturers can enhance productivity, reduce operating costs, and better meet the demands of both domestic and international markets.

6. Conclusion

AMS is committed to accompanying mold manufacturing enterprises, not only by providing products but also by delivering optimal solutions to enhance production efficiency. In the increasingly competitive mold industry, the adoption of advanced technologies and technical solutions will be the key for Vietnamese businesses to rise strongly. Contact AMS today for expert consultation on solutions tailored to your production needs!

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797