What Makes TRUE IMAGE TECHNOLOGY in Heidenhain Encoders So Unique?

True Image Technology is Heidenhain's exclusive optical innovation integrated into their encoders. This article explores what makes this technology special, how it works, and why it's becoming a game-changer for manufacturers across industries from robotics and semiconductors to wind energy, steel, and medical devices.

1. Why is a solution like TRUE IMAGE TECHNOLOGY necessary?

In production environments where dust, oil, or moisture is present, encoders (position sensors) must be protected from these damaging elements. The common solution is to inject clean air (usually compressed air) into the device to create positive pressure, preventing contaminants from entering. This method is known as using purge air.

However, relying on purged air leads to higher operating costs due to the need for compressors and frequent maintenance. It increases the total cost of ownership (TCO) and indirectly contributes to CO₂ emissions through energy consumption.

What happens when purged air is not used? The worst-case scenario is when the sensor becomes inaccurate due to optical interference (caused by water droplets or dust refracting light). This leads to machine performance issues and off-spec output quality.

Machines cannot function without encoders and to keep those encoders running reliably, they've traditionally needed purged air systems. As manufacturers look to optimize both cost and environmental impact, the question arises:

Is there a more advanced solution that can solve this challenge? The answer lies in True Image Technology, developed and engineered by Heidenhain. This technology has pushed Heidenhain's measurement systems to exceptional performance levels, making them a trusted, high-tech companion for any manufacturer.

2. What Is TRUE IMAGE Technology?

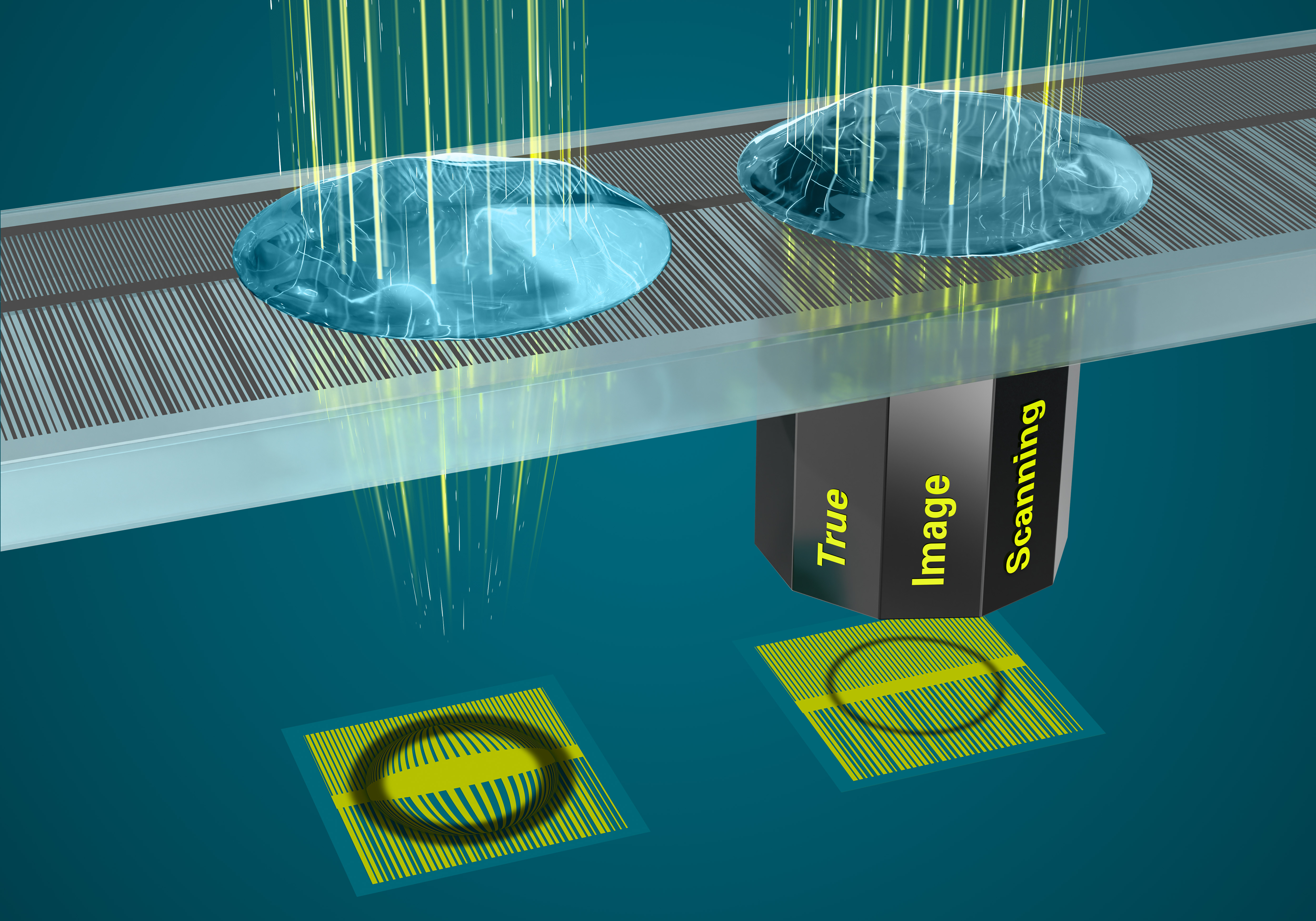

TRUE IMAGE Technology is an innovation that ensures accurate measurement even under contamination without the use of purge air. Optical distortion typically caused by contaminants on the encoder scale is completely eliminated by a special light-guiding element.

For example, even if there are dirty water droplets on the scale, the graduation lines are still clearly transmitted to the scanning head.

Unlike conventional encoders, which may suffer from position data errors when exposed to liquid or dust contamination, encoders with integrated TRUE IMAGE Technology are designed to ignore environmental interference and deliver highly accurate feedback.

With two core features: optical interference suppression and maintaining undistorted, parallel light paths despite oil or liquid contamination—this technology is considered a significant breakthrough in the evolution of integrated metrology solutions worldwide.

3. Key Benefits of TRUE IMAGE TECHNOLOGY

What makes this technology truly stand out lies in its ability to address the pain points of modern manufacturers. Below are the top advantages of using encoders integrated with TRUE IMAGE TECHNOLOGY - especially for manufacturers seeking long-term stability, high accuracy, and cost-optimized operations.

3.1. No Need for Purge Air

In many cases, even without a purge air system, Heidenhain encoders with TRUE IMAGE Technology still deliver accurate signals. This marks a major shift in how encoders operate in contaminated environments. As a result, manufacturers benefit from reduced system complexity and lower total cost of ownership (TCO).

3.2. Long-Term Accuracy in Harsh Industrial Conditions

Encoders are responsible for delivering precise measurement—and TRUE IMAGE plays a crucial role by minimizing optical interference caused by oil droplets, water, or other contaminants.

This ensures measurement integrity is maintained over time, even in the toughest production environments.

3.3. Minimized Maintenance and Machine Downtime

With TRUE IMAGE, there's no longer a need for frequent checks on pneumatic systems or manual cleaning of the scale. This results in shorter maintenance intervals, less machine downtime, and higher overall production efficiency.

3.4. Support for Sustainable and Eco-Friendly Manufacturing

By eliminating purge air, TRUE IMAGE reduces indirect CO₂ emissions from compressors and auxiliary systems. This is a huge advantage for factories aiming to implement green manufacturing models or meet ESG standards in global supply chains.

4. Which Heidenhain Encoder Series Feature TRUE IMAGE TECHNOLOGY?

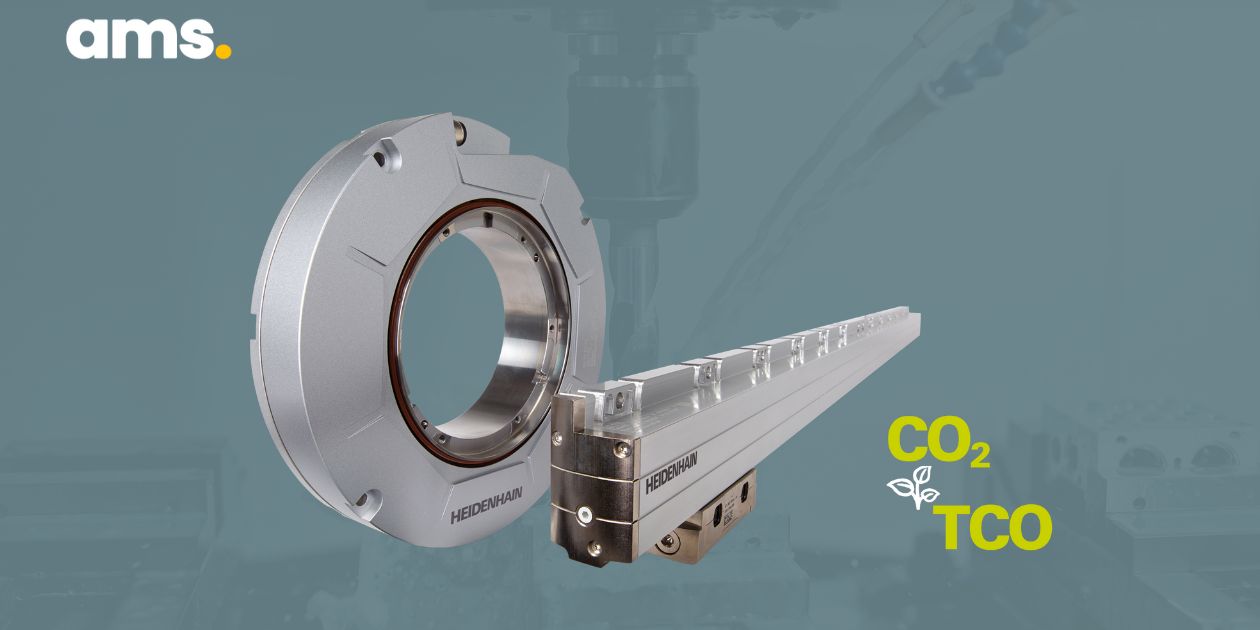

4.1. LC Series 6 - Linear Encoders

The LC Series 6 is designed to measure the position of linearly moving axes in CNC machines.

It is widely used in:

- Milling machines

- Machining centers

- Drilling, turning, and grinding machines

- Automation and production equipment

The LC Series features a sealed enclosure that protects the encoder from dust, chips, and liquids - making it highly suitable for harsh machining environments

>> See more:

4.2. RCN Series 1 - Absolute Angle Encoders

The RCN Series 1 includes absolute angle encoders with integrated bearings, designed for rotary position measurement. Common applications include:

-

C axes on turning machines

-

Rotary tables and swivel heads

-

Direct-drive motors requiring high precision

These encoders offer high-resolution feedback and reliability even in complex mechanical setups - thanks to the integration of TRUE IMAGE TECHNOLOGY.

>> See more:

5. Is TRUE IMAGE Worth the Investment?

TRUE IMAGE is not just another experimental upgrade or uncertain innovation. It's a strategic step forward in cost optimization and a clear move toward sustainable manufacturing.

Our expert team strongly recommends that if you are operating in industries where high accuracy is critical, investing in encoders equipped with TRUE IMAGE TECHNOLOGY is absolutely worth it.

The long-term benefits will speak for themselves. Investing in advanced solutions always leads to competitive advantages and measurable results.

Time is valuable - the time spent evaluating, repairing, or maintaining outdated systems could be the same time your competitor is already shipping out another batch.

At AMS, we believe that every smart investment counts, especially when it comes to placing your trust in Heidenhain solutions we proudly distribute.

6. Conclusion

TRUE IMAGE Technology, integrated into Heidenhain encoders, is one of the most advanced measurement solutions now available in Vietnam - exclusively distributed by AMS. Our experienced technical team is always ready to support manufacturers and answer any questions you may have about these products.

Let us know what machines you're using. Tell us your concerns - AMS will help you solve them. Contact us today!

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797