What is the TD 110 Tool Breakage Sensor? Discover How the TD 110 Optimizes Time and Increases Machining Efficiency

Released in 2025 by Heidenhain, the TD 110 tool breakage sensor stands out with its advanced technology and outstanding performance. It effectively addresses the issue of undetected tool breakage during machining, which can compromise output quality and lead to wasted time and costs.

At Heidenhain, each solution we develop aims to give manufacturers a competitive edge in today's rapidly evolving manufacturing landscape. So, what exactly is the TD 110? Which machines or production processes is it best suited for? Let's explore how the TD 110 can enhance productivity and streamline your operations.

1. What is the TD 110 Sensor?

The TD 110 is a non-contact tool breakage detection sensor. While it does not physically touch the tool, it uses high-speed rotational sensing to detect whether the tool is broken.

This solution is widely used in CNC machining and precision engineering. The TD 110 is mounted on machine tools to inspect drills, reamers, taps, and milling cutters helping prevent defective workpieces caused by undetected tool breakage.

2. Applications and working principle

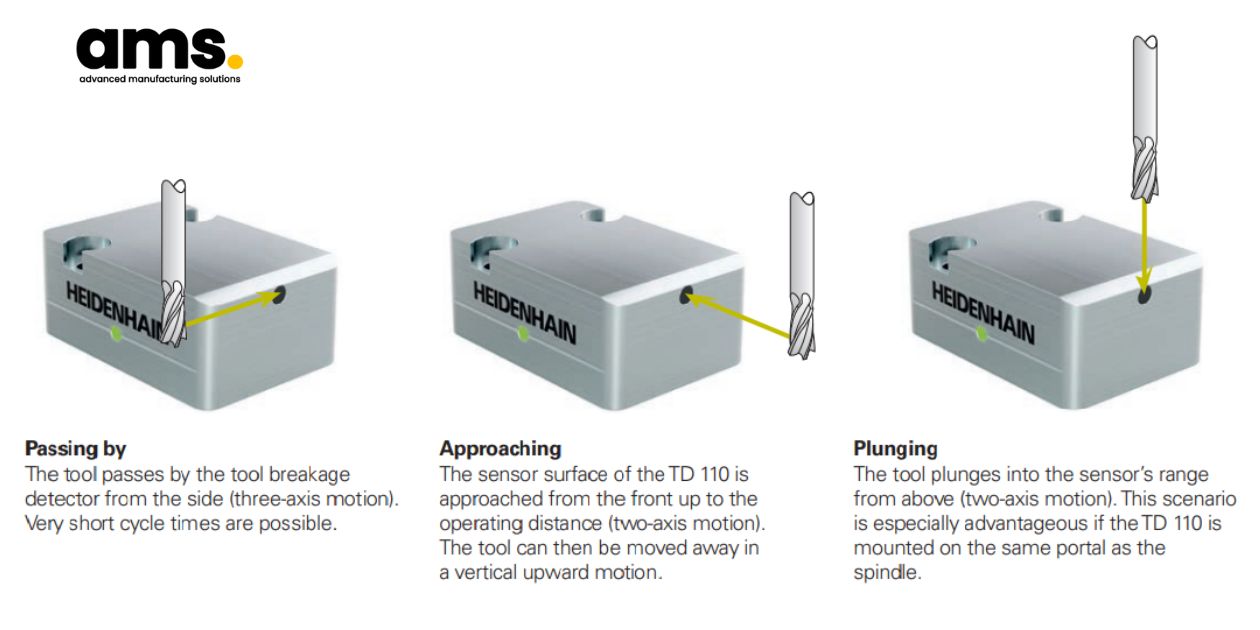

The tool breakage detector can be positioned in the work envelope such that it is easily accessible during tool changes at rapid traverse. The inductive sensor can detect tools as they pass by while they are spinning at their operational speed, or at least at 1000 rpm. Thanks to its rapid scanning technology, even very small tools made of HSS steel or carbide are detected.

For use on all controls, the breakage sensor generates a floating trigger signal and an HTL switching signal. The control can evaluate these signals via standardized instruction sets. In addition, an LED indicates whether a tool has been detected. As a result, machines already in use can benefit from automated breakage detection as well.

3. Benefits of TD 110 probe in production

Improve process reliability: The TD 110 tool breakage detector can reduce scrap and prevent secondary damage. Since it doesn't require a teach-in process, it can be used to inspect microtools in single-part manufacturing.

Reduce your system costs: Because it doesn't require compressed air, the TD 110 tool breakage detector can lower your TCO. And since it requires only one cable and zero maintenance, it can even cut costs.

Reduce machine idle time: The TD 110 tool breakage detector can be up to six seconds faster per tool change than laser-based systems. It can reduce idle time even further when combined with the process monitoring functionality of the TNC7. This inductive sensor also integrates seamlessly into your workflow at the current spindle speed.

Flexible retrofitting: Any control can be retrofitted with the TD 110. Remote support is available for installation in TNC controls. The breakage detector's small, nondisruptive form factor simplifies the installation process. And depending on the application, the same type of cable can be used for both the breakage detector and the TT 160.

4. What types of machines or processes are suitable for the TD 110 probe?

4.1. Detection Horizontal mounting

| Supported tools | Passing by | Approaching | Plunging | |

|---|---|---|---|---|

| Type | End mills, drills, taps, thread formers, ball-nose cutters, radius cutters | |||

| Material | Carbide, HSS | |||

| Minimum diameter for nominal scanning distance | 0.4 mm | 0.5 to 1 mm | 1 mm | 1 mm |

| Minimum rotational speed (Recommended) | 1000 rpm | 5000 rpm | 1000 rpm | 1000 rpm |

| Feed rate (Rapid traverse recommended) | ≥ 3 m/min | ≥ 20 m/min | ≥ 3 m/min | ≥ 3 m/min |

| Operating distance | ≤ 0.5 mm (nominal: 0.3 mm) | |||

| Minimum tooth length | 2 mm | |||

| L-OFFSET | Corner radius or corner chamfer, if > 1 mm | |||

| Breakage criteria |

|

|||

4.2. Vertical mounting

| Supported tools | Passing by | |

|---|---|---|

| Type | End mills, drills, taps, thread formers, ball-nose cutters, radius cutters | |

| Material | Carbide, HSS | |

| Minimum diameter for nominal scanning distance | 0.6 - 1 mm | ≥ 1 mm |

| Minimum rotational speed (Recommended) | 5000 rpm | 1000 rpm |

| Feed rate (Rapid traverse recommended) | ≥ 20 m/min | ≥ 3 m/min |

| Operating distance | ≤ 0.5 mm (nominal: 0.2 mm) | |

| Minimum tooth length | 2 mm | |

| L-OFFSET | Note: The tool must be measured all the way to the tip | |

| Breakage criteria |

|

|

5. Where to Buy Genuine TD 110 Sensors?

Choosing the right supplier for the TD 110 sensor is a critical factor in ensuring both application efficiency and reliable after-sales technical support. A genuine sensor not only guarantees quality and accuracy, but also helps businesses avoid risks associated with substandard products such as lack of documentation, poor performance, or no support in case of issues.

When purchasing a TD 110 sensor, manufacturers should consider the following:

-

The product must come with official certification and a clearly identifiable product code.

-

Technical documentation should be provided, along with expert consultation.

-

The supplier should offer installation, calibration, and maintenance support during operation.

AMS - Your Trusted Partner in Precision Engineering and Measurement Solutions

With years of experience delivering technical solutions to factories, AMS is an authorized distributor of the TD 110 sensor. Our clients span across mold making, precision machining, and industrial manufacturing sectors.

When purchasing the TD 110 sensor from AMS, you will benefit from:

-

Genuine products with complete documentation and traceable serial numbers.

-

Technical support from our team of experienced engineers.

-

Dedicated warranty policies and application consulting services.

6. Conclusion

The TD 110 sensor is more than just an auxiliary device it is a strategic tool that helps manufacturers optimize setup time, enhance machining accuracy, and boost overall productivity. In today's increasingly competitive manufacturing landscape, adopting advanced measurement solutions like the TD 110 not only reduces operational costs but also contributes to building long-term production advantages.

If you're looking for an effective solution to improve reliability and productivity in your machining processes, the TD 110 is a choice you shouldn't overlook.

Contact AMS today for expert consultation and experience a cutting-edge solution that keeps your factory running smoothly every day.

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797