Answers from A-Z about prestigious and quality Norton grinding wheels

Norton grinding wheels are an optimal choice for many manufacturing units. Norton has been in the market for a long time, founded in 1985 in the United States under the name Norton Company, the brand has expanded globally and is in the top 400 largest industrial companies in this country. In the Vietnamese market, manufacturers aiming for optimization, prestige and quality always have a demand for Norton grinding wheels. AMS is proud to be a distributor of Norton grinding wheels with reasonable economics, dedication and reliability. Let's explore some of the most frequently asked questions that you may also be looking for answers about this type of grinding wheel.

1. Overview of the Grinding Wheel Market

Before diving into the top questions about Norton grinding wheels, AMS would like to provide you with some valuable insights into the abrasive and polishing materials market. These details highlight how the demand and trade activities driven by your manufacturing and business operations are actively contributing to the growth of the abrasive and polishing industry.

The latest market research report from Mordor Intelligence on the super abrasives market—categorized by materials such as diamond and boron nitride with diverse applications including abrasives for manufacturing end-users (aerospace, automotive, industrial sectors, etc.)—has highlighted the Asia-Pacific region as the fastest-growing market compared to other regions like North America and Europe.

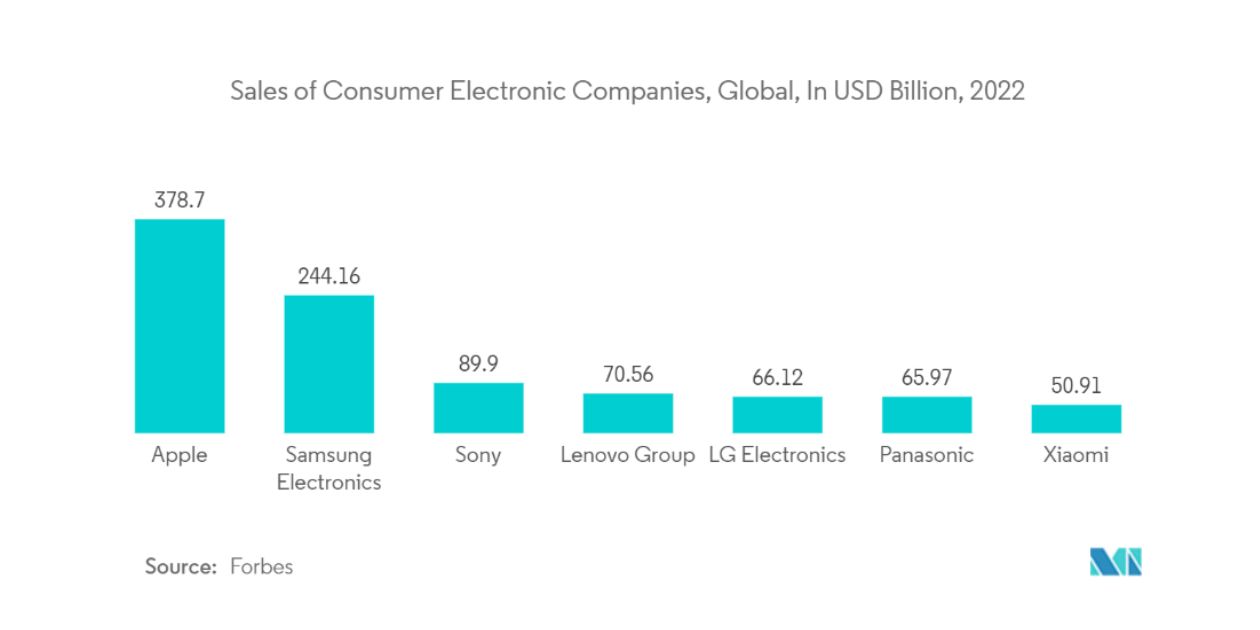

Among the major players in this thriving market is Saint-Gobain, the globally renowned manufacturer of Norton grinding wheels. The report also indicates that the growth of the abrasives industry is significantly driven by industrial sectors, particularly the electronics field. The increasing demand for advanced electronic devices in countries like India, China, and Japan plays a pivotal role in this rapid expansion.

According to the International Organization of Motor Vehicle Manufacturers (OICA), China remains the largest automobile producer, accounting for approximately 32.5% of global production. The country manufactured 26,082,220 vehicles in 2021, reflecting a 3% increase compared to 25,225,242 units in 2020. These figures highlight the growth of the automotive industry, which heavily relies on essential abrasive materials and tools, driving the parallel development of polishing and abrasive materials.

Vietnam, also part of the Asia-Pacific region, is still in the early stages of its mechanical engineering industry. However, promising signs from certain industrial sectors reveal potential for abrasives. According to the General Statistics Office, the machinery and equipment production index in Vietnam rose by 4.6% in the first nine months of 2024 compared to the same period in 2023. It is estimated that this index will grow by 5% for the full year compared to 2023.

Overall, the grinding wheel market shows significant growth potential, with increasing market demand fueled by the development of manufacturing industries.

2. Frequently Asked Questions About Norton Grinding Wheels

In the context of increasing market demand for abrasive and polishing materials, especially buyers looking for information and have some questions about grinding products from reputable brands. Below are some of the most frequently asked questions about Norton grinding wheels so you can rest assured to buy reputable, quality products.

2.1. Explain the concept of grinding wheel types

a, What is a Grinding Wheel?

A grinding wheel, also known as a grinding disc, is a tool used to remove material from the surface of a workpiece for grinding or polishing purposes. A grinding wheel is made of abrasive grains bonded together with a bonding material. During the grinding process, the grinding wheel and the workpiece come into contact, generating significant heat.

In summary, the overall performance of a grinding wheel depends on the factors that make up the grinding wheel, including: Abrasive material, bonding material, grinding wheel structure, wheel grade, size, type of grinding wheel, grinding wheel speed.

b, What are CBN Grinding Wheels and Diamond Grinding Wheels?

CBN grinding wheels and diamond grinding wheels are types of grinding wheels made from CBN (Cubic Boron Nitride) and diamond materials, respectively. Depending on the application and the hardness of the material being ground, users select either a CBN grinding wheel or a diamond grinding wheel.

Simply put, CBN and diamond are abrasive materials that serve as the primary components in the composition of grinding wheels. The wheels are named after these materials. Due to the differences in material composition, each type of grinding wheel exhibits unique grinding properties.

To learn more about CBN and diamond grinding wheels, you can explore What is a grinding wheel? Quality, genuine grinding stones at good prices

2.2. Are Norton Grinding Wheels a Good Choice?

Before you proceed to purchase a shipment, do you have some questions surrounding the purchase decision, such as Are Norton Grinding Wheels a Good Choice? Are there any grinding wheels that are superior to Norton at a more affordable price? AMS understands that the decision to purchase any product for the factory is based on the most optimal benefit. Here, considering the efficiency and optimal price worthy of quality, AMS believes that Norton grinding wheels are one of the top choices for you.

Norton has reasons to dominate the market, thanks to advanced technology and continuous quality improvement. Norton has proven to be up to 30% more effective than conventional grinding wheels.

>> See more:

2.3. Which Norton Grinding Wheel Should You Choose?

Norton offers a wide range of grinding wheels tailored to various applications. Here's a guide to help you select the right grinding wheel based on the surface material:

Painted or Varnished Wood:

Before applying a fresh coat of paint or varnish to wooden surfaces—whether it’s furniture or walls—you need to sand off the existing coating. The choice of abrasive material depends on the tools you have and the size of the surface.

-

For hand sanding: Consider Norton G131F sanding rolls, K20N sanding rolls, or T100 sanding sheets.

-

For machine sanding: Velcro sanding sheets (Expert or H231 models) are excellent options.

Raw Wood: In woodworking or furniture production, achieving a smooth finish on raw wood surfaces is essential. For angle grinders: Norton Expert cup grinding wheels for wood and concrete, lightweight grinding stones, or semi-flexible Norton grinding discs are recommended.

Metals: Materials like steel, stainless steel, or aluminum require a polished surface. Norton offers a complete range of grinding tools to help you achieve a mirror-like finish, from coarse to fine polishing. Based on your tools (hand tools, grinders, angle grinders, or drills), choose specialized metal/stainless steel grinding wheels or fiber discs like Norton F100.

Wall Panels, Concrete, Gypsum, and Stone: Construction materials also benefit from grinding applications. Norton provides a variety of grinding tools to meet these needs. Recommended tools include: K20N sanding sheets and specialized stone grinding discs.

To select the right grinding wheel and tools, consider: What material are you grinding? What tools will you use, and how will the process be performed? For tailored recommendations, consult our experienced team to ensure you find the most suitable grinding wheels and tools for your specific needs.

2.4. Where to buy reputable and quality Norton grinding wheels?

Reading this far, you must have understood the application of grinding wheels on different types of materials. The next step is to complete the process of purchasing Norton grinding wheels according to the quality standards required by your boss. You will wonder why you should choose a Norton grinding wheel supplier instead of buying from the manufacturer, we will show you some of the following reasons:

-

Not optimizing the purchasing process for your business, by choosing to buy directly from abroad, you will waste time contacting, exchanging and waiting for feedback from the genuine manufacturer, tracking international orders with a series of customs paperwork, taxes, fees, …

-

Difficult to receive technical support due to geographical distance and immediate information exchange

Prioritize choosing cost optimization, a dedicated consulting team, flexible purchasing policies and commitment to progress. AMS is proud of our history of working with customers who have accompanied us for more than 2 decades. Choose AMS to buy reputable, quality Norton grinding wheels to meet your production schedule today!

3. Conclusion

Choosing the right grinding tool for the material is important. The demand for grinding wheels in the market comes from meeting the increasing requirements of industries and manufacturing. Not only a machining tool, grinding wheels are also the optimal solution to improve efficiency, quality, and competitiveness of products. Contact AMS Vietnam for advice on the most suitable grinding wheels for your business!

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797