Overview of Vietnam's Can Manufacturing Industry and the Growing Demand for Can Die Polishing

Can die polishing is essential for improving surface quality in both can manufacturing (canmakers) and can tooling/die production. As demand for metal cans continues to rise, manufacturers face increasing pressure to maintain production capacity, efficiency, and quality. Ensuring that can dies remain in optimal condition is crucial to achieving these goals.

So how can manufacturers keep their tooling in perfect working condition? What should they look for when choosing a polishing solution for can dies? Let's explore the Vietnamese can manufacturing landscape and the growing demand for can die polishing with AMS.

1. What Are Can Dies?

Can dies are precision tools used to form, shape, and finish aluminum or steel cans for beverage, food, or aerosol packaging. They are typically made from tool steel or tungsten carbide, offering high hardness, wear resistance, and the ability to withstand significant forming pressure.

A complete can body requires multiple dies and tooling components, including:

-

Body die

-

Necking die

-

Base reform die

-

Ironing ring

-

Dome die

Because can dies are the heart of every can manufacturing line, their condition directly influences:

-

Can surface finish

-

Dimensional accuracy

-

Production speed

-

Scrap rate

This makes regular can die polishing and maintenance vital to consistent performance and cost efficiency.

>> See more: Towards Sustainable Manufacturing: Why Surface Finishing Also Needs to Go Green

2. Overview of Vietnam's Can Manufacturing Industry

A growing industry always stimulates supporting sectors and AMS aims to understand this ecosystem to support manufacturers with appropriate polishing solutions for both maintenance and original equipment.

According to a report by Mordor Intelligence, Vietnam's metal can packaging market is valued at USD 2.17 billion in 2025 and is expected to reach USD 2.53 billion by 2030, with a CAGR of 3.07%.

This growth is driven by:

-

Rapid urbanization

-

A young and expanding population

-

Rising demand for convenience foods and beverages

Additionally, Vietnam benefits from domestic hot-rolled steel supply, helping local manufacturers avoid China-related anti-dumping tariffs.

With government support including circular economy initiatives for closed-loop can recycling and preferential FDI policies Vietnam's can packaging market is rapidly advancing and becoming a leader in sustainable innovation.

As competition intensifies, “production optimization” has become a strategic priority for can manufacturers. At the same time, strict quality and productivity standards require consistent can die maintenance and polishing to avoid costly downtime and defects.

3. Why Manufacturers Must Prioritize Can Die Polishing

To maintain a competitive advantage, canmakers must reduce waste, minimize downtime, and extend tooling life. This starts with selecting the right can dies and maintaining them properly.

Key considerations include:

-

Even a 0.001% deviation in die geometry on a high-speed production line can generate tons of scrap.

-

Every minute of downtime for die inspection or troubleshooting faulty cans can halt the production of thousands of units.

-

Losses multiply rapidly when die defects affect multiple lines or facilities, leading to significant cost escalation annually.

These risks highlight why can die polishing is essential. Polishing should be performed when:

-

Dies show signs of wear

-

Surface defects appear on cans

-

During scheduled maintenance cycles

-

After heavy production runs

4. AMS - Your Trusted Provider of Hyperion Polishing Solutions for Vietnam's Can Industry

AMS proudly supplies high-quality polishing products designed specifically for demanding industrial applications. Below are some of our most trusted and widely used products among canmakers and tooling manufacturers:

-

Polishing Goals: Can Die Maintenance & Restoration

Product Grit size Hyperion diamond compound DMSY SJK-5-2-4 MOS5 2-4 micron (approx. 3 micron) Hyperion diamond compound DMSY SJK-5-4-8 MOS 5 6 micron Hyperion diamond compound DMSY SJK-5-20-30MOS5 25 micron Hyperion LUB K400 (500ml) Lubricating oil -

Abrasive belts for punch texturing / scratch patterning

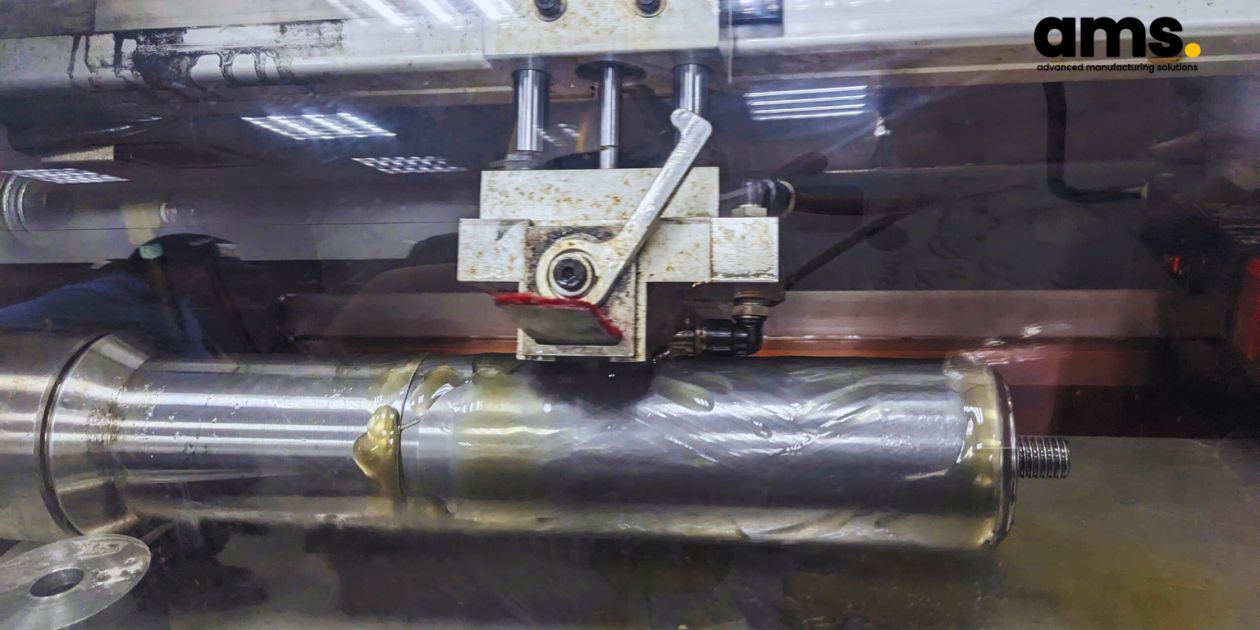

Actual photos at the factory taken by AMS

As Vietnam's authorized distributor of Hyperion, AMS provides:

-

Genuine, high-quality products

-

Competitive pricing

-

Clear documentation

-

Fast, reliable supply

-

Dedicated support throughout the purchasing and maintenance process

5. Conclusion

AMS is committed to supporting Vietnam's can manufacturers in optimizing performance at every stage from die selection to polishing and maintenance. As Hyperion's trusted commercial partner, we strive to provide high-quality polishing solutions at competitive prices, ensuring manufacturers receive the best value for their investment. We look forward to collaborating with you to enhance product quality and advance Vietnam's canmaking industry. Contact AMS today!

AMS Company, Ltd.243/9/10D To Hien Thanh str, Hoa Hung Ward, HCMC, Vietnam

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797