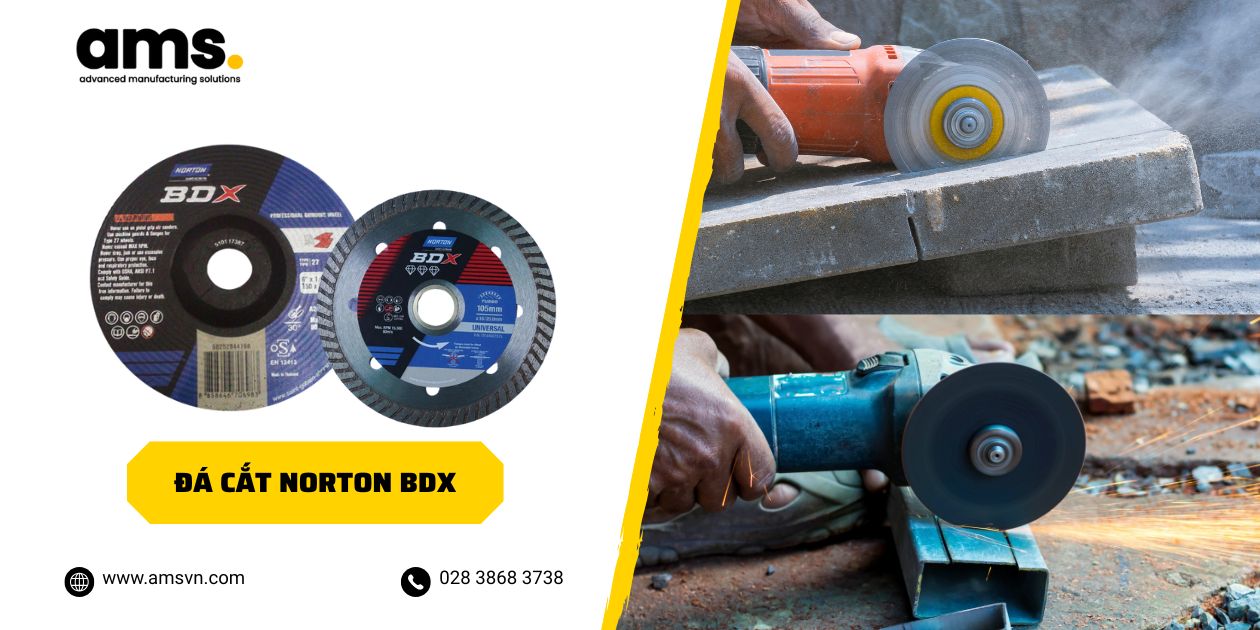

Discover the Advantages of Norton BDX Cutting-off wheel

Norton BDX cutting-off wheels are part of the world-famous Norton brand and are proudly distributed by AMS. Whether you're searching for a cutting solution to support your manufacturing or grinding operations across any industry, AMS is confident in delivering your needs with speed, dedication, and trust.

1. What is a Norton BDX Cutting-Off Wheel?

A cutting-off wheel (also known as a cut-off wheel) is an abrasive tool made from high-quality coarse or medium-grade grains. Its primary function is to cut through various types of metal such as stainless steel, carbon steel, aluminum, and other alloys. These wheels are typically used with handheld power tools to perform material cutting tasks. Common tools include chop saws, angle grinders, and die grinders.

Norton is a globally recognized brand, especially known for its high-performance abrasives, including grinding wheels and cutting-off wheels. Part of the BDX product line, Norton cutting-off wheels, grinding wheels, and diamond tools offer versatile solutions across a wide range of applications. They are compatible with both handheld and stationary machines, making them ideal for different types of industrial use.

2. Common Applications of Cutting-Off Wheels

Cutting-off wheels are essential tools in various industries due to their wide range of applications, including:

-

Metalworking: In mechanical engineering and metal fabrication, cutting is a crucial step in producing components and parts made from materials like steel, aluminum, and copper. Each type of metal may require a specific cutting-off wheel to ensure optimal performance and precision.

-

Stone and Tile Processing: In the construction industry, cutting-off wheels are used to cut, shape, and grind stones and tiles. These tools help save time and energy, contributing to faster and more efficient workflows.

-

Woodworking: Cutting-off wheels are also applied in cutting and shaping materials such as MDF and plywood, supporting the production of furniture and construction components.

Overall, in fast-growing sectors such as automotive, motorcycles, electrical appliances, and electronics, nearly every product consists of components that must be cut and shaped. The Norton BDX cutting-off wheel plays an indispensable role in manufacturing these parts. Choosing the right wheel for your application ensures faster processing, reduced effort, and greater time savings.

3. Cutting-Off Wheels vs. Grinding Wheels: What's the Difference?

At first glance, cutting-off wheels and grinding wheels may look quite similar in shape and size. However, they serve different purposes and are constructed with distinct features to meet specific application needs. Below are some key differences between the two:

| Cutting-Off Wheel (e.g., Norton BDX cutting-off wheel) | Grinding Wheel | |

|---|---|---|

| Material | Made primarily from softer abrasive grains that break away easily during use, exposing fresh cutting edges. This allows the wheel to make fast, clean cuts even on hard materials. | Composed of harder abrasive grains with better bonding strength, designed for durability and finer surface finishes. |

| Function | Used to cut through materials into desired shapes and sizes. | Used to grind, smooth, and finish surfaces of materials. Ideal for the final steps of processing. |

| Structure | Has a higher grit level for increased friction, enabling more effective cutting. Cutting-off wheels are typically thinner and have a smaller diameter compared to grinding wheels. | Features a lower grit level and is generally thicker than cutting-off wheels, offering more control and durability for surface finishing. |

4. Advantages of Norton BDX cutting wheel series

-

Faster stock removal by 20% vs. competition

-

Longer life than competition

-

Long Life (LL) items for additional enhanced durability

-

Quality consistency

-

oSa / EN 12413 certified

-

80 m/s MOS for grinding wheel

5. Explore the Versatility of Norton BDX Cutting-Off Wheels

Norton BDX cutting-off wheels are available in a wide range of product lines, designed to meet the diverse needs of customers across different industries and applications.

| Application | T41 Cutting | |

|---|---|---|

| Steel/ Stainless | A30S-100X2.5X16.0-T41 NOR-BDX | 66252841095 |

| Steel | A24R-100X2.5X16.0-T41 NOR-BDX | 66252925573 |

| Steel | A24R-125X2.5X22.23-T41 NOR-BDX | 66252925574 |

| Steel | A24R-150X2.5X22.23-T41 NOR-BDX | 66252925575 |

| Steel/ Stainless | A24R-180X2.5X22.23-T41 NOR-BDX | 66252925576 |

| Steel/ Stainless | A30S-125X2.5X22.23-T41 NOR-BDX | 66252844000 |

| Application | T41 Chopsaw | |

| Steel/ Stainless | A24T-300X3.0X25.4-T41 NOR-BDX LL | 66253371092 |

| Steel/ Stainless | A24T-350x3.0x25.4-T41 NOR-BDX LL | 66252926348 |

| Steel/ Stainless | A24T-400X3.0X25.4-T41 NOR-BDX LL | 66253371017 |

| Steel/ Stainless | A30R-300X3.0X25.4-T41 NOR-BDX | 66252926342 |

| Steel/ Stainless | A30R-350X3.0X25.4-T41 NOR-BDX | 66252926346 |

| Steel/ Stainless | A30R-400X3.0X25.4-T41 NOR-BDX | 66252926347 |

| Application | Ultra Thin Cut T41 | |

| Steel/ Stainless | A46V-100X1.6X16.0-T41 NOR-BDX | 66252925614 |

| Steel/ Stainless | A46V-125X1.6X22.23-T41 NOR-BDX | 66252925615 |

| Steel/ Stainless | A46V-180X1.6X22.23-T41 NOR-BDX | 66252925617 |

| Steel/ Stainless | A60T-105X1.0X16.0-T41 NOR-BDX | 66252836053 |

| Steel/ Stainless | A46T-105x1.2x16.0-T41 NOR-BDX | 66252839256 |

| Application | T27 Grinding | |

| Steel | A24R-100X6.0X16.0-T27 NOR-BDX | 66252844162 |

| Steel | A24R-125X6.0X22.23-T27 NOR-BDX | 66252844163 |

| Steel | A24R-150X6.0X22.23-T27 NOR-BDX | 66252844168 |

| Steel | A24R-180X6.0X22.23-T27 NOR-BDX | 66252844164 |

| Steel/ Stainless | A24T-100X6.0X16.0-T27 NOR-BDX LL | 66252926336 |

| Steel/ Stainless | A24T-125X6.0X22.23-T27 NOR-BDX LL | 66252926337 |

| Steel/ Stainless | A24T-150X6.0X22.23 -T27 NOR-BDX LL | 66253371747 |

| Steel/ Stainless | A24T-180X6.0X22.23-T27 NOR-BDX LL | 66252926338 |

| Application | T27 Flexible wheels | |

| Steel/ Stainless | WA80-100X2.5X16.0-T27 NOR-BDX | 66252844159 |

| Steel | AC46S-125X3.0X22.23-T27 NOR-BDX | 66253371377 |

| Diamond Blade | ||

| Universal | 105x1.4x7Hx20/16 Turbo Fast Cut | 70184607575 |

6. 12 Safety Tips for Using Cutting-Off Wheels in Manufacturing and Installation

To ensure safe and efficient use of Norton BDX cutting-off wheels, always follow these essential guidelines:

-

Do not place the grinder on the floor or workbench while the wheel is still spinning.

-

Never use the cutting machine in areas with high fire or explosion risks.

-

Avoid entering areas where grinding sparks are active.

-

Only trained and knowledgeable personnel should replace or test cutting/grinding wheels.

-

Do not use wheels that have been dropped or suffered strong impacts.

-

Never force a wheel onto a machine if it does not fit properly; do not enlarge the hole manually.

-

Do not exceed the maximum speed rating indicated on the wheel.

-

Avoid using flanges that are rusty, deformed, or dirty.

-

When tightening the flange, do not overtighten the nut.

-

Do not use cutting-off wheels for grinding purposes.

-

Never touch the wheel while it is rotating, under any circumstances.

-

When testing a new wheel, avoid standing in the direction of its rotation.

7. Conclusion

We hope this article has provided you with valuable insights into the Norton BDX cutting-off wheel product line. If you're looking for high-quality, genuine cutting-off wheels at competitive prices along with dedicated and reliable service don't hesitate to contact AMS today!

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797