How does periodic mold maintenance and polishing bring economic benefits?

Regular polishing and mold maintenance provide significant economic benefits for manufacturing businesses. This article revolves around answering the questions of why businesses need to perform regular mold maintenance. How do they provide economic benefits to producers? How to choose a reputable and quality supplier of materials and tools for mold polishing? Let's explore the following article together with AMS!

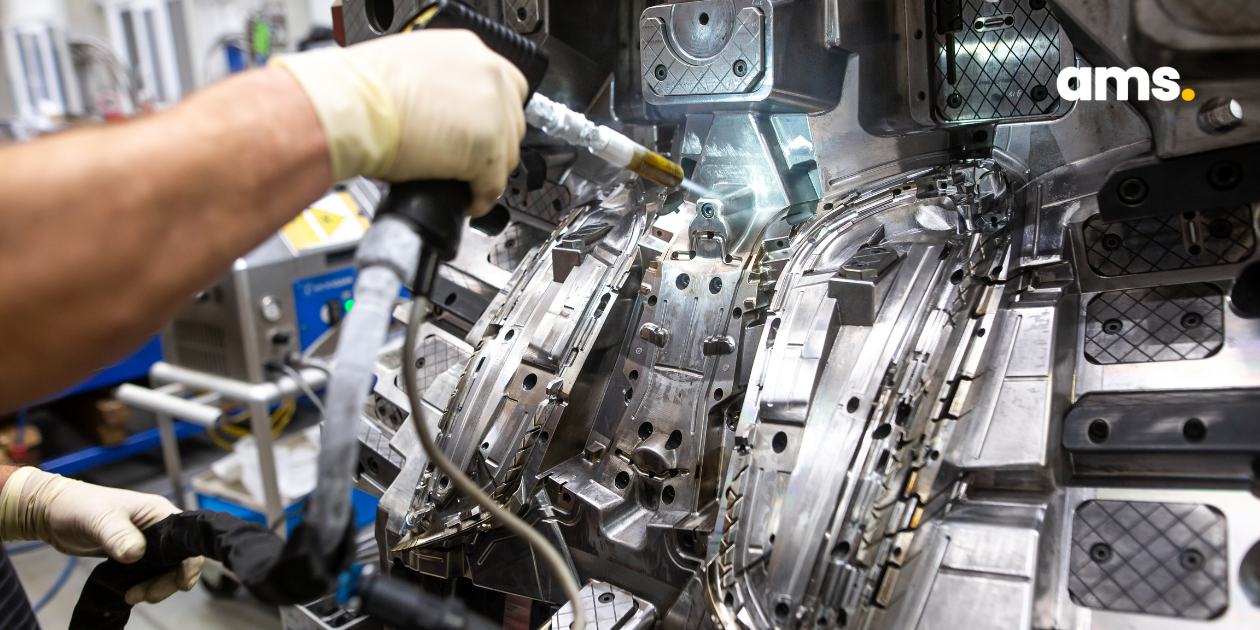

1. Why is it necessary to polish and maintain molds regularly?

1.1. The importance of regular mold maintenance.

Nowadays, mold production activities in Vietnam are developing stronger than ever as the government focuses on investing in the manufacturing sector, especially the demand for molds among plastic manufacturers. According to the Vietnam Financial Magazine, plastic product exports in the first six months of 2024 are expected to see a strong increase, reaching over 3.15 billion USD, up more than 32% compared to the same period in 2023. Nevertheless, in recent times, the foreign sector has viewed the Vietnamese plastic industry as a "tasty piece of cake," as the scale of this industry reached 22 billion USD last year. The mold plays a very decisive role in creating quality, reputation, and brand for the manufacturer. Therefore, the process of negotiating, buying, and collaborating on mold production is not simple.

The results mentioned above highlight the importance of mold quality in production for products to meet quality standards in both domestic and international markets. However, aside from mold quality, a situation that many businesses seem to overlook has led to outcomes that are not as desired. The process of polishing and maintaining molds regularly is still lacking in rigor; some managers and engineers overlook proposals for regular mold maintenance, only carrying out polishing and servicing when damage occurs or issues arise.

AMS believes that when businesses have a plan for timely mold maintenance, proper care, and standardization. The value of the plastic manufacturing industry will further increase, and the fields of mold manufacturing, machining, and polishing will also be strongly promoted for development in the near future.

>> See more: Expert Insights: Unraveling 6 Effective Mould Polishing Techniques

1.2. Common issues encountered if molds are not regularly maintained.

A mold is created to cast products; a quality mold will withstand impacts and natural wear during its use. However, no matter how high-end the mold is, it will still face temperature fluctuations over time, leading to cracks in the mold. The worst thing for a manufacturer is when the mold has issues, leading to a series of widespread repercussions, typically including:

-

Reduce product quality and increase the amount of waste: The cracked mold leads to an imperfect final product, and the substandard quality of the product diminishes the manufacturer's reputation. In cases where the product is unusable, it results in an increase in waste, causing a waste of raw materials.

-

Technical issues: It is important to mention the sudden technical incidents; instead of maintaining the molds to optimize production and save effort, time, and money, manufacturers have to allocate costs to fix the problems. These are certainly risks that a manufacturer can anticipate and should make wise choices regarding regular mold maintenance.

-

Decreased productivity and rising costs: Inefficient operations that cause machinery to consume excessive energy are a concerning issue for imperfect molds. This results in increased operating costs and decreased overall system efficiency. Not only does it stop there, but the lack of regular maintenance for molds leads to rapid deterioration. When they break down, they need to be replaced, and the company ends up incurring much higher costs for new replacements compared to regular maintenance.

-

The manufacturer's reputation is affected: We can clearly see that the lack of regular mold maintenance leads to many negative consequences, but what will cause the manufacturer's reputation to be impacted? Defective molds affect the production process, and the final product may not meet standards, or if it does, the manufacturer faces the risk of delayed delivery. Time is always a promise, representing the credibility of businesses. Delaying delivery deadlines simply due to a lack of regular maintenance is truly unacceptable.

Not polishing molds and regularly maintaining them is revealing a series of potential risks for manufacturers in the future. Maintenance activities are not difficult but play an important role in the production process of a business.

2. How do regular polishing and maintenance of molds provide economic benefits?

Polishing and regularly maintaining molds is significant and important in the production process. To avoid facing any arising risks during production, this step is a necessary requirement. Below are the outstanding advantages regarding the economic benefits of polishing molds.

2.1. Increase productivity and profit

Any business hopes to achieve increased productivity and profits, which demonstrates that the business is continuously growing. Especially for manufacturers, there are many factors that influence the increase in productivity and profit. Optimize the process, ensuring that machinery and equipment operate smoothly so that the output meets the required standards for both quality and quantity, which necessitates regular maintenance of the molds. Minimize technical incidents and downtime, optimize the use of raw materials thoroughly, ensure output quality meets standards, and utilize long-lasting production molds... The factors mentioned above will help producers increase productivity and profits in the long term.

2.2. Cost-saving in production

Every incident that arises causes the business to incur costs for resolution; one of the greatest benefits for manufacturers is to minimize any additional costs as much as possible. The wise choice of manufacturers is to invest in regular mold maintenance, which is a long-term investment strategy that brings lasting benefits. As previously shared, the maintenance costs for plastic molds, metal molds, etc., are much lower than purchasing new ones or fixing issues.

>> See more: Mold Polishing - No more a headache for manufacturers

3. AMS: Choosing a reputable supplier for maintenance and polishing materials for molds.

In general, there are many issues and consequences if manufacturers do not maintain molds regularly, and there are also numerous economic benefits when companies decide to invest in mold polishing and regular maintenance. However, in order to proceed with polishing the mold and testing, there are requirements for materials and supplies related to the polishing technique. Units are once again faced with the challenge of selecting distributors for the aforementioned products to ensure quality and reliability.

AMS Company Limited Top Polishing Products supplier in Vietnam's Mould & Die Industry, proudly boasts years of extensive experience along with high-quality products from manufacturers with top global brands.

The team of experts always understands the concerns of customers regarding mold maintenance, mold polishing, and a variety of issues related to materials and supplies in the polishing industry. AMS connects and supports its customers with utmost dedication and professionalism, providing optimized and personalized solutions tailored to meet the diverse needs of our clients.

Don't hesitate to contact AMS today for assistance with your polishing requests. We have everything you need, with a commitment to quality, reputation, authenticity, and prompt service at a reasonable cost. Let AMS accompany your organization on the journey towards sustainable and prosperous development!

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797