Superhard Abrasive Materials - Genuine CBN Powder and Solid Boron Nitride CBN

CBN (Cubic Boron Nitride) is a material that has become familiar in the precision mechanical industry. Famous for its outstanding hardness, second only to the world's rarest material, diamond, CBN also has the ability to withstand extremely high temperatures. CBN has become a necessary condition for the cutting and grinding sector to become sufficiently accurate and durable. Let's find out with AMS how CBN is applied in the manufacturing industry.

1. Overview of CBN (Cubic Boron Nitride) Material

1.1. What is CBN?

CBN (short for Cubic Boron Nitride) is a synthetic crystalline compound made of boron and nitrogen, with a structure similar to that of diamonds. Due to the tight bonding of its constituent atoms, CBN exhibits exceptional hardness, even surpassing diamonds in certain applications.

The hardness and wear resistance of CBN are remarkable, with hardness ranging from 4000 to 4500 kg/mm² (on the Vickers hardness scale). This property makes CBN a reliable and optimal material for grinding and machining hard materials such as steel alloys.

While diamonds decompose at 700°C, CBN remains stable at 1,300°C in the presence of air. This demonstrates CBN’s superior thermal resistance, making it highly suitable for metal machining, especially in steel alloys, where temperatures exceed what diamonds can endure.

Lastly, the chemical inertness of CBN is an important advantage. Boron nitride does not react with ferrous materials, making CBN the optimal choice for machining iron-containing materials like alloy steel, stainless steel, and other hard materials.

1.2. Applications of CBN in Industry

In industry, the properties of CBN have established its importance and indispensability in the era of industrialization and modernization, particularly in the fields of cutting, grinding, and polishing in metalworking. Below are some typical applications of CBN in the industrial sector:

-

Application in Tool Manufacturing: This is a crucial application of CBN. CBN cutting tools offer many advantages over traditional cutting tools. Due to the high cost of CBN production, it is primarily used to manufacture certain metal cutting tools and small cutting inserts, such as tips added to cutting inserts for turning tools. CBN is also used to enhance the hardness, durability, and sharpness of grinding tools and cutting blades for better performance and longer tool life. CBN is also utilized in indexable milling cutters.

-

Another application of CBN is in grinding and polishing materials. For surfaces requiring high precision and a flawless finish, CBN is the optimal choice, surpassing other materials. A typical example is the use of Hyperion abrasive compounds, which include micron CBN powder as a substrate at the tip of workpieces to improve the grinding and polishing performance of tools such as milling cutters, grinding wheels, and other abrasive products. Industries that prioritize CBN include automotive manufacturing, aerospace, and medical device production.

>> See more: 5 Pros and Cons of using Diamond Slurries and CBN Slurries

2. Classification of CBN Powder and Solid CBN

2.1. About CBN Powder

CBN powder is a form of CBN that is manufactured into ultra-fine particles with a diverse range of sizes, from micron to nano scale, ensuring flexibility in applications such as grinding, cutting, and polishing. CBN powder is primarily used in fine grinding processes that require extreme precision and smooth surface finishes.

The particle size determines the application of CBN in various stages of polishing:

-

Coarse particles (large micron): Large CBN particles are typically used in the pre-processing stage, where the surface of the material needs to be flattened or major defects need to be removed.

-

Fine particles (small micron and nano): In the final polishing stage, fine CBN powder particles are used to create a highly polished and exceptionally smooth surface. This is especially suitable for manufacturing devices that require absolute precision, such as in mold making, the semiconductor industry, and precision engineering.

2.2. About Solid CBN

Solid CBN is a form of CBN manufactured into solid blocks with high hardness, typically used for producing industrial grinding and cutting tools. Solid CBN is often made into cutting blades, grinding wheels, or precision grinding components that require high precision and the ability to withstand heavy loads in manufacturing processes.

Solid CBN generally exists in two main forms:

-

Cutting Blades: Solid CBN is manufactured into industrial cutting blades with high durability, capable of withstanding heavy forces and high temperatures. These blades are commonly used in the cutting of alloy steel, stainless steel, and other difficult-to-machine metals. If you are looking for metal cutting tools, you can refer to Sandvik tools distributed by AMS.

-

Grinding wheels and grinding stones: CBN blocks are manufactured into grinding wheels or grinding stones with stable structures, used in high-precision grinding processes. These grinding wheels are capable of maintaining sharpness and accuracy for a long time, even when operating under harsh conditions. Norton is one of the very famous brands that supply grinding stones, ensuring quality if you are interested. To save on international shipping costs, complicated customs purchasing processes, you can buy Norton grinding wheels at AMS, we are the official distributor of Norton in Vietnam.

3. Benefits of Using Genuine CBN Products from AMS

It is evident that boron nitride is widely and extensively used in the field of precision engineering and metalworking, from polishing, grinding, to cutting. As a result, there is always a demand in the market for mechanical components made from CBN material. The issue for manufacturers is not the scarcity of the material, nor the difficulty in finding suppliers, but rather ensuring that the supplier meets their expected criteria.

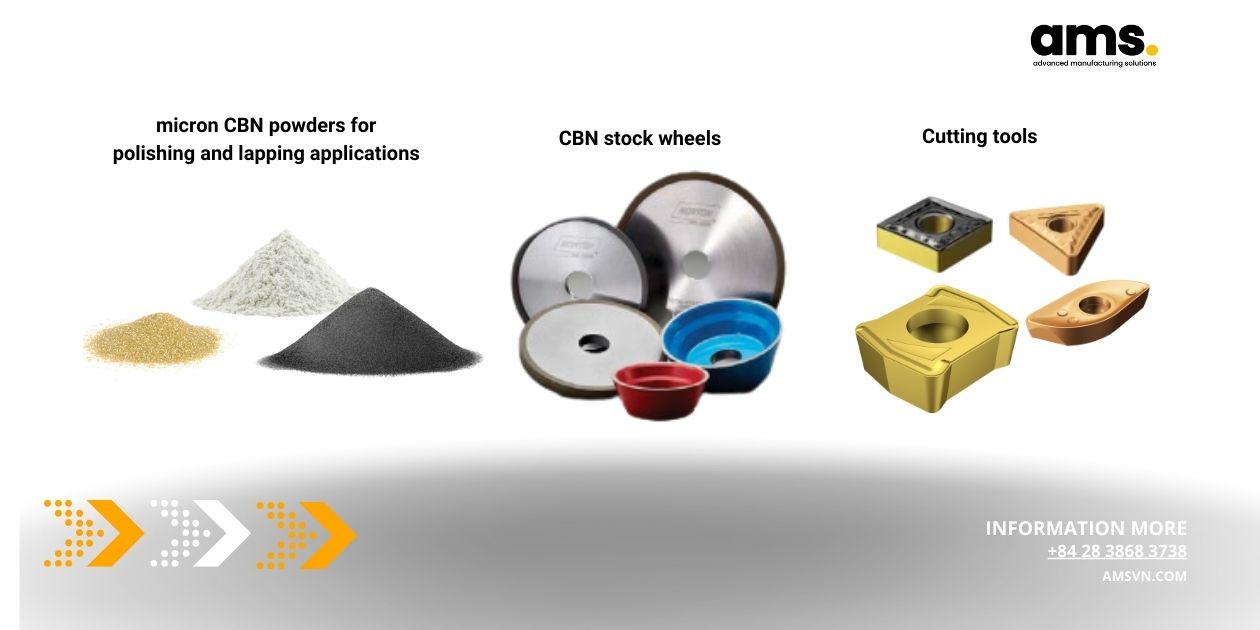

At AMS, we provide products with CBN materials according to demand. Specifically:

-

Metal cutting tools such as milling, turning, boring, ... from the Sandvik Coromant brand with more than 150 years of history.

-

CBN grinding wheels and grinding wheels from the Norton brand, with a long history since 1885, famous worldwide.

-

CBN powder and CBN polishing solution, AMS distributes products from the Hyperion brand, an American brand with 100% quality commitment

AMS, with 21 years of experience accompanying manufacturers, has gone through many ups and downs of the market, understanding the desires of Vietnamese businesses, especially manufacturers. We bring:

-

Genuine products, European and American quality but at Asian prices

-

Commitment to the supply chain according to the agreed time, businesses do not have to worry about import documents, customs taxes, ... AMS contributes to optimizing the purchasing process for businesses

-

AMS has a policy of after-sales sales, customer care after purchase and dedicated technical consulting support when customers have difficulties in operating the product.

Choosing the optimal supplier means choosing economic benefits for your business, invest in a long-term relationship for sustainable development in the future. Get advice today!

>> See more: What are the solutions to the 5 biggest challenges facing Vietnam's precision engineering industry?

4. Conclusion

AMS has provided detailed information about the superhard grinding material CBN, including a thorough analysis of its various forms and shaped products, along with their different applications and functions. We hope that manufacturers have found the CBN products that suit their needs and wish you continued growth and success in the future.

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797