Explore the Encoder Catalog for the Electronics Industry

Our encoder catalog for the electronics industry offers in-depth insights into the applications of different encoder types across various electronic manufacturing machines. This article is especially useful if you're looking for high-precision encoder solutions that enhance performance and efficiency in production. Discover more with AMS in the detailed guide below.

1. Overview of Vietnam's Electronics Industry Market

According to the General Statistics Office, as of September 2024, Vietnam's exports of electronics, computers, and components reached $52.8 billion. On the global technology map, Vietnam ranks 5th in computer and component exports and 2nd in mobile phone exports.

Electronics manufacturing plants, with investments ranging from tens of millions to billions of dollars from major corporations and enterprises from South Korea, the U.S., and other countries, have played a pivotal role in helping Vietnam maintain an annual technology export turnover exceeding $100 billion in recent years.

The primary export markets for Vietnam's electronics sector include the U.S., Europe, China, and South Korea. In the past year alone, exports of computers, electronic components, and mobile phones to Europe and the Americas totaled $56.9 billion, accounting for nearly 45% of total export revenue.

With the presence of multinational manufacturers such as Samsung, Foxconn, and Intel, along with commitments to expand production, Vietnam continues to attract interest from global corporations exploring investment opportunities. This signals a promising future, positioning Vietnam for transformation, acceleration, and breakthrough growth.

Amid the evolving electronics manufacturing landscape and the rapidly increasing production demand, manufacturers in Vietnam face significant challenges related to machinery and production equipment. There is a growing need for reliable suppliers that can provide timely equipment, spare parts, and maintenance solutions to support seamless and efficient production.

2. The Importance of Encoders in the Electronics Industry

In the electronics industry, encoders play a crucial role in automation systems by enabling precise control and monitoring of equipment operations. According to a report by Markets and Markets, the global encoder market is projected to reach $3.7 billion by 2026, growing at a CAGR of 8.6% per year.

Within electronic device manufacturing, encoders support robotic systems, fixed arms, conveyor belts, and quality control systems. Advances in motion and measurement technology have laid the foundation for further innovations, including the miniaturization of components. This includes smaller semiconductor molds in front-end manufacturing, increased chip complexity in back-end processing, and higher component density on printed circuit boards (PCBs), all of which have propelled the electronics industry forward.

3. Types of Encoders for the Electronics Industry

There are two main types of encoders: Incremental Encoders and Absolute Encoders. Each type has its own distinct characteristics, an absolute encoder stores the absolute position value even when power is lost. When power is restored, it can immediately provide the exact position without needing to recalibrate the reference point. In contrast, an incremental encoder generates pulse signals to measure speed and direction of rotation, commonly used in motor control and motion monitoring applications.

These two encoder types exist in two physical forms:

-

Rotary Encoder: Used in robotic systems and conveyor belts.

-

Linear Encoder: Supports precise position measurement.

Depending on operational requirements and machinery compatibility, electronics manufacturers can select the most suitable encoder type. Today, the market offers a wide range of encoders with diverse specifications from leading brands such as RSF, Heidenhain and more, ensuring optimal solutions for industrial automation.

4. When to Replace an Encoder?

Unexpected machinery component failures can disrupt production efficiency. Therefore, plant engineers should be aware of common encoder issues to proactively maintain or replace faulty components, ensuring seamless operations.

Here are some common encoder failures:

-

Encoder Malfunction: This occurs when internal components fail to generate or transmit accurate waveforms. In such cases, replacing the encoder or repairing internal components is necessary.

-

Connection Issues - Faulty Cables: One of the most frequent causes of encoder failures, especially during maintenance. If cables are exposed, short-circuited, or have poor contact, they should be replaced immediately. Additionally, ensure cables are not overly tight, as this can loosen or break solder joints. Secure connections properly to maintain stable operation.

-

Power Supply Issues: If the supplied voltage is too low or exceeds the encoder's resistance threshold (which varies by brand and model), the encoder may become unstable. This can result from weak power sources or excessive transmission loss through cables. Inspect and repair the power supply or replace faulty cables if needed.

-

Improper Installation: If the encoder is not securely mounted, positional accuracy may be compromised, leading to severe misalignment. Regularly check and tighten the encoder to ensure secure installation.

-

Other factors may also cause encoder failures, sometimes requiring a full replacement. If you encounter any issues, AMS's experienced engineers are ready to assist you. Contact us at 028 3868 3738 for support!

5. AMS Encoder Solutions - Meeting Every Industry Demand

At AMS, our mission is to deliver cutting-edge technical solutions to manufacturers, particularly in Vietnam. We take great pride in being the exclusive distributor of Heidenhain, providing high-performance encoder solutions across various industries, contributing to the advancement of the economy.

AMS serves a wide range of sectors, including aerospace, precision engineering, mold manufacturing, and more. Below are the encoder solutions we offer to support manufacturers in the electronics industry.

5.1 Encoder Solutions for Front-End Semiconductor Manufacturing

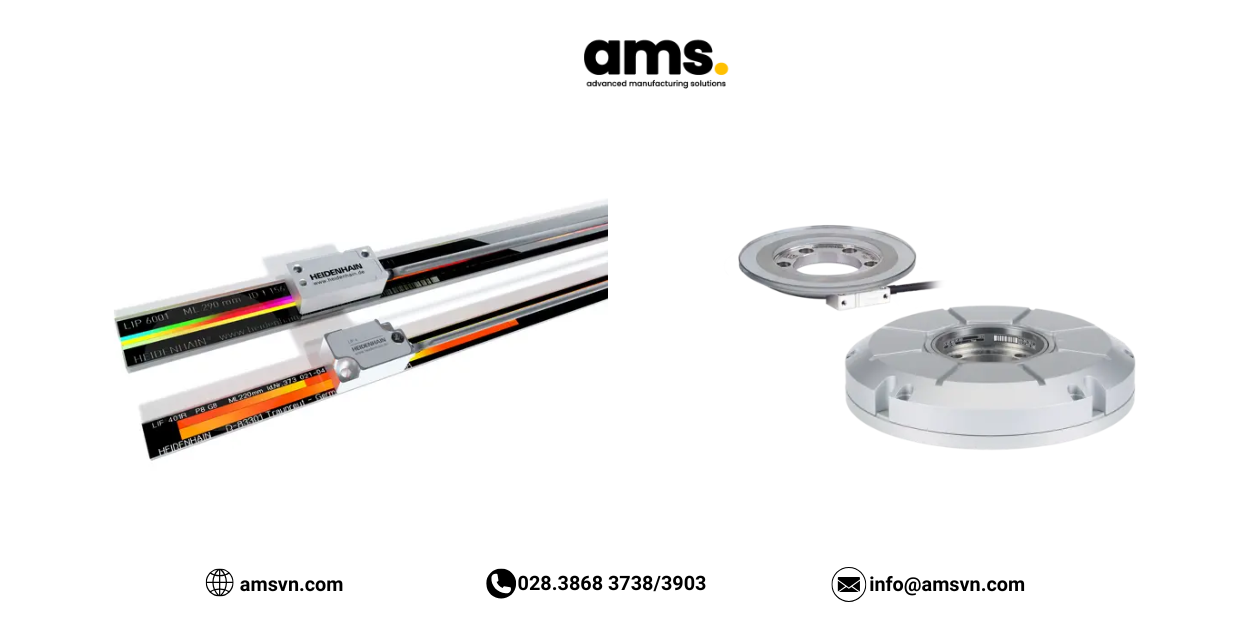

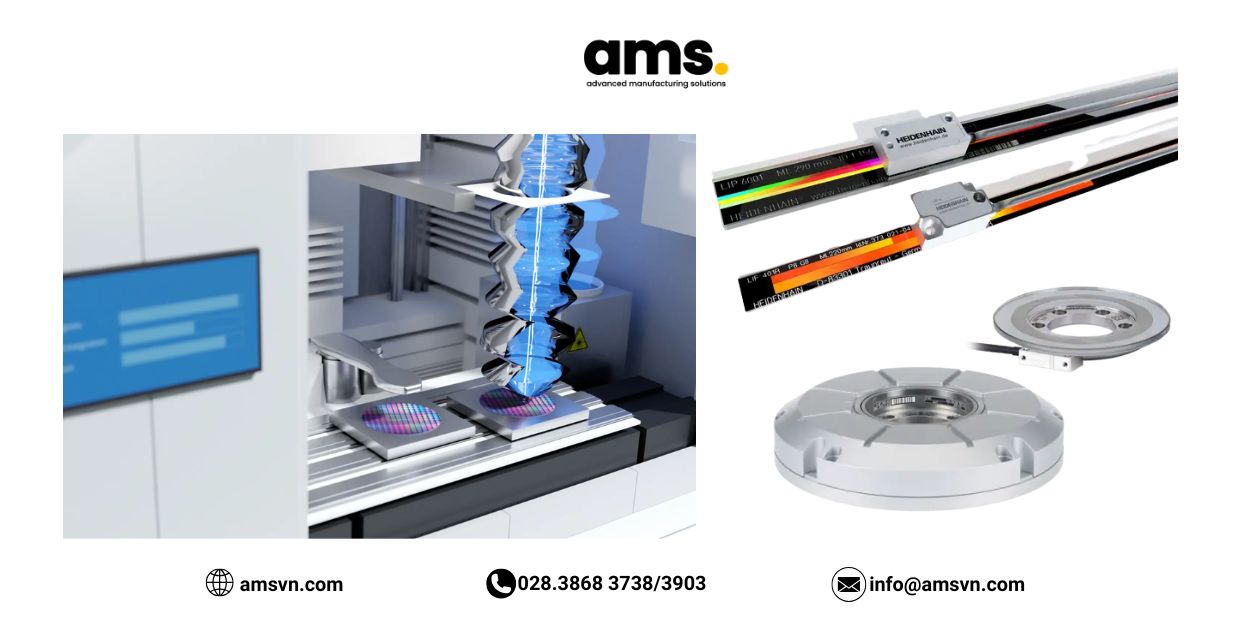

HEIDENHAIN's exposed linear encoders are optimized for high-precision and long-term stability in front-end semiconductor manufacturing. The modular, bearingless ERP series optical angle encoders are designed for large hollow shafts and high-speed spindle applications—reaching up to 20,000 RPM—reducing inertia while eliminating the need for additional startup torque.

Additionally, ETEL's motion systems offer solutions ranging from single X-axis to full seven-axis systems, catering to diverse semiconductor manufacturing applications. By integrating HEIDENHAIN control technology with ETEL’s expertise in motor solutions, these systems achieve bidirectional repeatability of ±250 nm, ensuring optimal performance.

>> Explore our product range here: Exposed Linear Encoders

5.2 Measurement and Motion Technology for Back-End Applications

Back-end semiconductor manufacturing demands exceptional precision and ultra-compact designs. High-accuracy rotary encoders play a crucial role in ensuring precise positioning of rotary axes in applications like die bonding and packaging.

-

HEIDENHAIN offers two key solutions: Modular optical angle encoders (ERP & ERO series)

-

MRP angle encoder modules, which integrate a high-precision bearing and encoder system, simplifying handling and installation while ensuring optimal accuracy.

>> Learn more about our solutions here: Angle encoder modules

5.3 Encoders for Electronic Assembly and PCB Manufacturing

.jpg)

In PCB assembly and electronic module production, processing speed is paramount. HEIDENHAIN's LIC and LIDA contact linear encoders provide high accuracy and fast travel speeds, making them ideal for these applications.

For large rotary axes in electronic assembly and PCB production, HEIDENHAIN's ERO and ERA optical modular angle encoders deliver high precision. The MRP angle encoder module offers an integrated machine component solution, eliminating the need for expensive post-installation adjustments.

Additionally, RSF's MCR 15 angle encoder series is specially designed for electric motor applications, providing a cost-effective alternative to air-bearing rotary axes.

>> Discover more about our solutions: Modular Angle Encoders

6. Conclusion

The encoder selection for the electronics industry is vast and diverse. We hope this article has helped our customers find the most suitable encoder solutions for their machinery and equipment. At AMS, we take pride in being the official distributor of Heidenhain and RSF encoders, ensuring high-quality, precision-driven solutions for the electronics industry. Thank you for your trust and partnership. We wish you continued success and growth!

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797