Encoder Applications in the Wind Energy Industry

AMS is a trusted distributor of high-performance encoders for the wind energy sector, offering solutions from globally recognized brands such as Heidenhain, AMO, and Leine Linde. In a demanding industry like wind power where extreme environmental conditions and rigorous reliability standards are the norm what requirements must encoders meet? How are encoders used in wind turbines? And why should wind turbine manufacturers choose encoders distributed by AMS? Discover the answers and explore our full guide to encoder applications in wind power below!

1. Driving Forces Behind the Wind Turbine Manufacturing Industry

The global demand for electricity is projected to grow by 4% this year and next, according to the International Energy Agency (IEA). By 2025, hydropower, solar, wind, and other renewable energy sources are expected to account for 35% of global electricity supply. Notably, solar energy is projected to meet half of the demand growth, while wind power will contribute approximately 25%. This underscores a growing global commitment to sustainable energy.

As part of this global shift, Vietnam has also committed to carbon-free development. Decision No. 2068/QD-TTg, issued on November 25, 2015, outlines Vietnam's Renewable Energy Development Strategy through 2030 with a vision toward 2050. It focuses on expanding electricity generation from renewable sources, particularly as nuclear projects are halted and fossil-fuel power is scaled back. (Source: Wikipedia)

Another key driver for the growth of wind energy is the decreasing cost of production, making wind turbines increasingly competitive in the global market. Although Vietnam's wind turbine manufacturing sector remains relatively modest compared to global standards, recent developments signal positive momentum.

In April 2024, CS Wind Vietnam (located in Phu My Industrial Zone, Ba Ria - Vung Tau Province) announced the export of 10 wind turbine towers, each with a capacity of 10MW, to South Korea. These towers will support the 99MW Jeonnam 1 Offshore Wind Project—the country's first commercial-scale offshore wind farm, located in the southwest province of Jeonnam.

These developments highlight the significant potential and untapped opportunities in the wind turbine manufacturing industry. As a provider of diverse technical solutions, especially in wind power, AMS is proud to contribute to innovation and support the sustainable advancement of Vietnam's energy industry.

2. Wind Turbine Components and How They Work

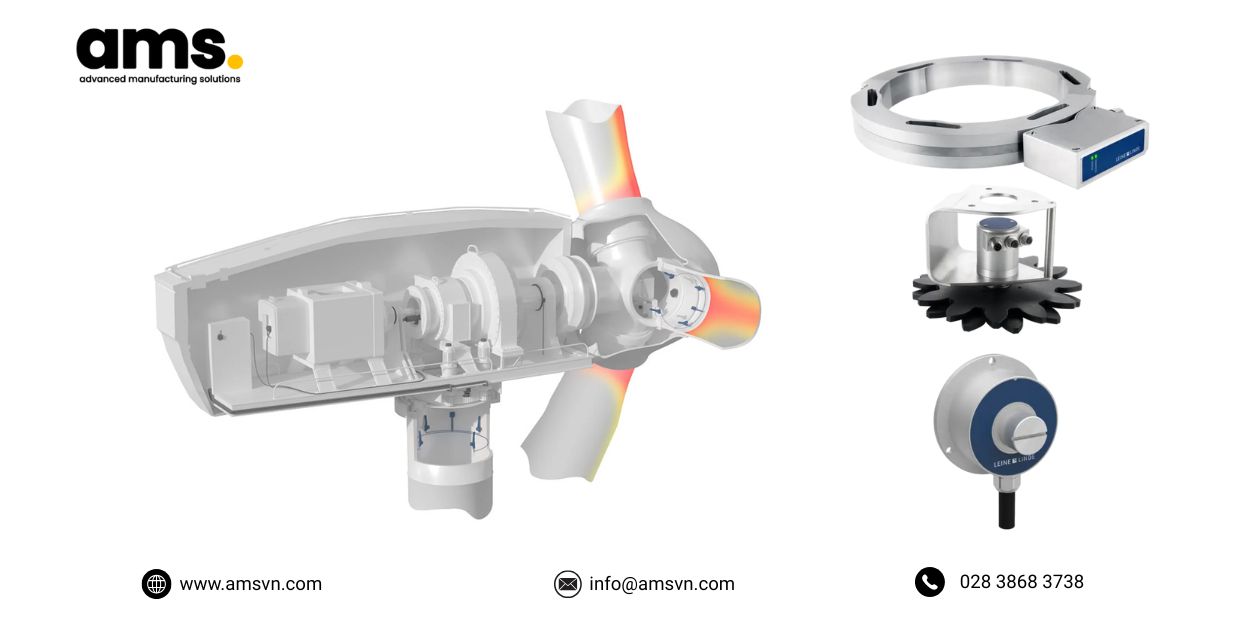

Before diving into encoder solutions for the wind energy sector, let's explore the structure and working principle of a wind turbine. At AMS, we proudly support both wind turbine component manufacturers and assembly partners with advanced technical solutions tailored to their needs.

A wind turbine is a type of mechanical equipment with a relatively straightforward structure, composed of the following key components:

-

Pitch System: Controls the angle of the blades to protect the rotor from strong winds and optimizes power output by maintaining stable, high-efficiency rotation.

-

Hub: Located at the center of the rotor, typically made of cast iron or steel. It transfers mechanical energy from the blades to the generator.

-

In turbines with a gearbox, the hub is connected to a low-speed shaft, converting wind energy into rotational force.

-

In direct-drive turbines, the hub transfers energy directly to the generator.

-

-

Rotor: The rotor includes the blades and hub, converting wind energy into rotational energy through lift forces generated by wind flowing over the blades.

-

Blades: These are aerodynamic structures that catch the wind, rotate, and drive the turbine's shaft to produce energy.

-

Brake System: Provides emergency stopping capability for the rotor to prevent damage in extreme conditions.

-

Gearbox: Connects the low-speed shaft of the rotor to the high-speed shaft of the generator, increasing rotational speed to generate electricity.

-

Yaw drive: Keeps the rotor facing into the wind, ensuring optimal energy capture.

-

Yaw motor: Powers the yaw drive to accurately position the turbine based on wind direction.

-

Tower: The steel structure supporting the nacelle and rotor. The higher the tower, the more wind energy can be harnessed, increasing electricity output.

-

Low Speed Shaft: Transfers slow rotational motion from the rotor to the gearbox.

-

High Speed Shaft: Transfers high-speed rotational energy from the gearbox to the generator.

-

Controller: Acts as the central control unit, managing the turbine's operations and safety systems.

-

Anemometer: Measures wind speed and transmits data to the controller for operational adjustments.

-

Wind vane: Detects wind direction and works with the yaw system to align the turbine properly.

-

Generator: Converts mechanical energy from the rotor into electrical energy.

-

Nacelle: The housing that encloses and protects critical components such as the generator, gearbox, and controller from external elements.

3. Solutions for wind turbines

Wind turbines may look similar on the outside, but the way they generate power behind the walls of their nacelle varies.

Wind turbines equipped with a gearbox can leverage the many benefits of a high-speed generator. These generators are compact and rotate much faster than the rotor. The results are greater efficiency and an electrical frequency that matches the power grid.

Wind turbines without a gearbox are more compact and contain fewer moving parts. But these benefits are offset by an expensive ring generator requiring ever greater weight for higher performance. Even for these generators, we provide reliable and easy-to-install modular encoders with very large diameters.

To discover sensors, encoders and slip rings designed for geared and gearless wind turbines, explore the products from HEIDENHAIN, AMO, LEINE LINDE and LTN below.

3.1. Encoders for measuring the rotational speed and position of generators

| Name | LEINE LINDE 800 | AMO WMR/WMK | LEINE LINDE M500 | LEINE LINDE 2000 |

|---|---|---|---|---|

| Feature |

Robust design and a long service life Common mechanical and electrical interfaces Cost-effective |

Bearingless measurement Immunity to magnetic and electrical fields Light and cost-effective design |

Bearingless measurement Immunity to magnetic and electrical fields Wide axial displacement tolerance |

Bearingless measurement Segmented ring for installation inside the drive train Low profile for tight spaces |

3.2. Encoders for measuring rotor speed and position

| Name | LEINE LINDE 500 | LEINE LINDE 600 | AMO WMR/WMK | LEINE LINDE 2000 | HEIDENHAIN ROC 413 |

|---|---|---|---|---|---|

| Feature |

Compact and versatile High adaptability Cost-effective |

Combination of incremental and absolute signal output Wide range of fieldbus interfaces Highly modular design and wide range of mechanical interfaces |

Bearingless measurement Ring scales with tension lock for large axes Stainless steel graduation carriers (two meters or longer) |

Bearingless measurement Segmented ring design and flange mount, ideal for large axis diameters Wide axial/radial scanning gap |

Compact optical encoder Integrated SSI+HTL signal output, specifically designed for slip-ring mounting Field-proven for decades |

3.3. Slip rings for transmitting data, power and signals

| Name | LTN SC105 | LTN SC168 | LTN SC330 | LTN K32ST |

|---|---|---|---|---|

| Feature |

Compact modular slip ring for data, power and signal transmission Perfect fit for hydraulic pitch systems Maintenance-free technology |

Hybrid modular slip ring for data, power and signal transmission Perfect fit for the latest electrical pitch systems The latest touchless data transmission (optional) |

High-power modular slip ring Specifically designed for blade heating systems Permissible current loads of up to 250 amps |

Touchless data transmission Maintenance-free design Robust, anodized aluminum enclosure |

3.4. Encoders for blade azimuth and pitch system motors

| Name | LTN RE58 | LEINE LINDE M500 | HEIDENHAIN EQI 1331 |

|---|---|---|---|

| Feature |

Enclosed resolver High immunity to harsh environments and EMC High adaptability |

Modular incremental inductive rotary encoder With and without a bearing IP6x rating for installation outside motor |

Absolute inductive rotary encoder with diagnostic functionality Bearingless measurement IP2x rating for installation inside motor |

3.5. Encoders for measuring the nacelle and rotor-blade positions

| Name | HEIDENHAIN ROQ 425 | LEINE LINDE 600 YAWMO® | LEINE LINDE 900 YAWMO® | LEINE LINDE 600 |

|---|---|---|---|---|

| Feature |

Optical rotary encoder with integral bearing Multiturn functionality for long downtime periods High reliability and proven technology |

Complete solution with absolute position encoder, mouting bracket and pinion wheel Pre-loaded wheel for backlash-free operation (optional) Standardized design, but still customizable to individual needs |

Functional safety with safety relay 25-year service life Complete solution with absolute position encoder, pinion wheel and mounting bracket |

Compact absolute encoder with inductive scanning Modular encoder platform with various mechanical and electrical interfaces Large bearing for direct pinion wheel mounting |

4. Conclusion

AMS is committed to delivering only genuine and cutting-edge technical solutions—especially high-performance encoder solutions for the wind energy sector. Contact AMS today for expert consultation and tailored solutions that meet your specific needs!

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797