Brass Wire - The perfect choice for the EDM machine

Brass wire is a widely known and popular material in many different industries. Before 1979, the cutting wire first used in EDM machines was red copper wire, after 1979, people replaced red copper wire with brass wire. So what are the outstanding advantages of brass wire that make it the first choice for equipment and machinery? Let's find out the details with AMS through the article below.

1. What is brass wire?

Brass wire is an alloy made of copper (Cu) and zinc (Zn), the compound combined from the two metals has created many characteristic and beneficial properties for brass wire. For more than 10,000 years, copper has been exploited to serve the extremely developed life, the outstanding features of copper such as durability, conductivity, wear resistance, ductility and ease of processing to suit many applications.

Manufacturing units can change the ratio of copper or zinc to create a type of copper wire that can meet the needs of customers. When the ratio of copper is higher than zinc, the copper wire is more flexible, easier to bend and draw, so it is easier to shape. Conversely, when the ratio of zinc is higher than copper, the brass wire will increase in durability and hardness.

2. Why is brass wire an excellent choice for EDM Machine

Because of the outstanding advantages derived from the metals that make up the brass wire, it is extremely famous for its flexibility. There are many fields that are using brass wire for many different purposes such as jewelry making, electronics, plumbing systems, etc. In this section, we will learn about choosing brass wire as the main material, also known as cutting wire in EDM machines.

Electrical discharge machining or electro-erosion is the corrosion of metal by electric sparks that can cut any conductive material, whether the material is hard or soft. It can be imagined that during the electro-discharge machining process, the machine will generate a large amount of heat and emit electrical pulses. Therefore, the materials used in EDM machines must meet the following criteria:

-

Good electrical conductivity

-

High melting point

-

High elongation

-

Good thermal conductivity

The explanation for why brass cutting wire is the perfect choice for EDM cutting machines is based on the composition of the cutting wire to divide it into 2 types:

2.1. Uncoated type

Copper, molybdenum, brass are the main components of traditional cutting wire. This type of cutting wire was commonly used before 1979 because of its high thermal conductivity and was often processed into wires with very small diameters. Then, brass appeared and replaced red copper wire as a spectacular step to the throne, brass cutting wire helps save time, improve processing speed. The zinc component in brass cutting wire has the ability to cool quickly and form zinc oxide, which tends to reduce wire breakage.

2.2. Coated type

As shared in the above section, brass wire meets all the criteria required for materials in EDM machines. In particular, cutting wire with brass material allows for penetration into the dielectric, core and coating of brass with high tensile strength and heat dissipation during the processing.

3. Discover some types of brass wire used in practice

There are many types of brass wire with different sizes and specifications. In this section, we will learn about 2 types of brass wire that have been trusted by AMS customers in recent times.

In fact, there are many suppliers of brass wire, GF is known as one of the suppliers of quality copper wire certified by experts. Before going to the detailed product description, let's find out why AMS recommends you brass wire of the GF brand for EDM cutting machines:

-

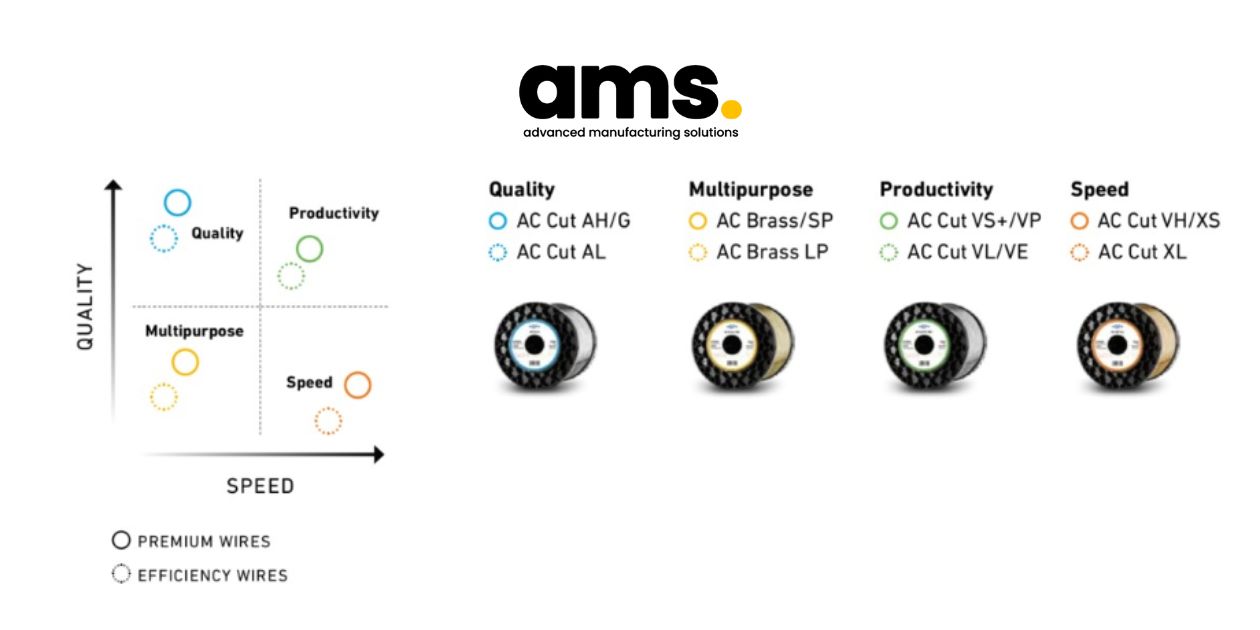

Fast speed: GF has a team of experts in product research and development for many years, the important thing for EDM cutting machines is that the spare parts must ensure optimal processing speed.

-

Quality: GF claims their brass wire has the best surface quality with perfect surface uniformity, highest precision in geometric details and parallelism of details

-

Productivity: GF brass wire focuses on productivity, which is the answer to all the productivity needs applied to mold, die and general mechanical processing

-

Versatile: No matter what type of machine you are using, GF brass wire has the ability to integrate and meet your needs

3.1. AC Brass 900

-

Product description:

| Specifications | ||||

|---|---|---|---|---|

| Wire Type | Material | Tensile | Elongation | Conductibility |

| AC Brass 900 | CuZn | 1000 N/mm2 | 15% | 22% IACS |

| Diameters (mm) Spool Type | AC Brass 900 | |||

| K160 (8kg) | 0.20 | 0.25 | 0.30 | |

| K200 (16kg) | ||||

| P5 (5kg) | ||||

-

AC Brass 900 is not only used in EDM machines, but also has suitable properties for applications that require flexibility and better conductivity, such as connecting wires and filters. In addition to the AC Brass 900 types with the above sizes and weights, the manufacturer has adjusted a variety of weights, tube sizes, ... to meet the needs of users, such as: AC BRASS 900 - 0.10 - 1 spool 1.8 kg; AC BRASS 900 - 0.15 - 2 spools 8 kg; AC BRASS 900 - 0.20 - 4 spools 4 kg; AC BRASS 900 - 0.25 - 1 spool 16 kg; ... and many more.

>> See more products: High-grade brass wire

3.2. AC Brass LP 1000

-

Product description:

| Specifications | ||||

|---|---|---|---|---|

| Wire Type | Material | Tensile | Elongation | Conductibility |

| AC Brass LP1000 | CuZn | 1000 N/mm2 | 15% | 22% IACS |

| Diameters (mm) Spool Type | AC Brass LP1000 | |||

| P5 (5kg) | 0.20 | 0.25 | 0.30 | |

-

When you need a high precision cutting wire for an EDM cutting machine, AC Brass LP 1000 will be the ideal choice, this wire is also suitable for electronic components. AC Brass LP 1000 - 0.25 - 2 spools 10kg; AC Brass LP 1000 - 0.2 - 2 spools 5 kg;... all types of quality, reputable brass wire to meet the diverse needs of customers.

>> See more products: AC Brass LP wire has the characteristic of being made from high alloy

4. Where to buy reputable - genuine - quality brass wire?

Nowadays, there are many places to buy brass wire, however, the quality of the cutting wire is carefully focused on. Because the quality of the copper wire is the deciding factor in the success of the EDM machining process. 100% uniformity and no defects or disturbances are the criteria that copper wire must meet. Any unevenness can affect the cutting performance and the quality of the final product.

Due to the application of brass wire, this material is very popular. Although most types of copper wire are imported products. However, in the Vietnamese market, there are many establishments importing poor quality copper wire products. For ordinary customers, identifying and choosing to buy high quality brass wire is a very difficult task.

Understanding the concerns of customers, AMS has connected with leading partners in Europe to import high quality products. Ensuring prestige, genuine commitment to units with demand for cutting wire (brass wire). We meet a variety of customer needs in terms of size, weight, elasticity, conductivity, ...

AMS technical consulting team is always ready to support customers when needed with all dedication, optimization and reliability. Contact AMS immediately to get a source of goods commensurate with the value that your unit expects!

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797