Polish Lapidary with Diamond Powder

Lapidary is the art of cutting, shaping and polishing stone or other hard materials to create jewelry, decorative objects and sculptures. This craft requires specialized tools and techniques. However, with the right attachments and diamond polishing compound, a beginner can handle almost any job.

1. Why should you use Diamond Powder to polish Lapidary?

The use of diamond powder in rough polishing provides the following benefits:

-

First, diamond powder is highly effective in polishing hard materials such as quartz, corundum and topaz, which can be difficult to use with traditional polishing compounds. Diamond powder can also be used to achieve high levels of polish on softer materials such as jade, turquoise and lapis lazuli, which is difficult to achieve with traditional polishing compounds.

-

Second, diamond powder is highly precise, allowing sculptors to achieve complex designs and shapes with greater precision. The fine diamond particles in the paste can reach even the smallest crevices and corners on the surface of the polished material, resulting in a more even and consistent surface. This precision is especially important in creating faceted gemstones, where corners and facets need to be polished to a high degree of precision.

-

Third, diamond powder is also highly durable, it can be used many times without losing its effectiveness. Unlike traditional polishing compounds, which can wear out quickly and need to be replaced frequently, diamond powder can be used for many subsequent polishing sessions, saving users money.

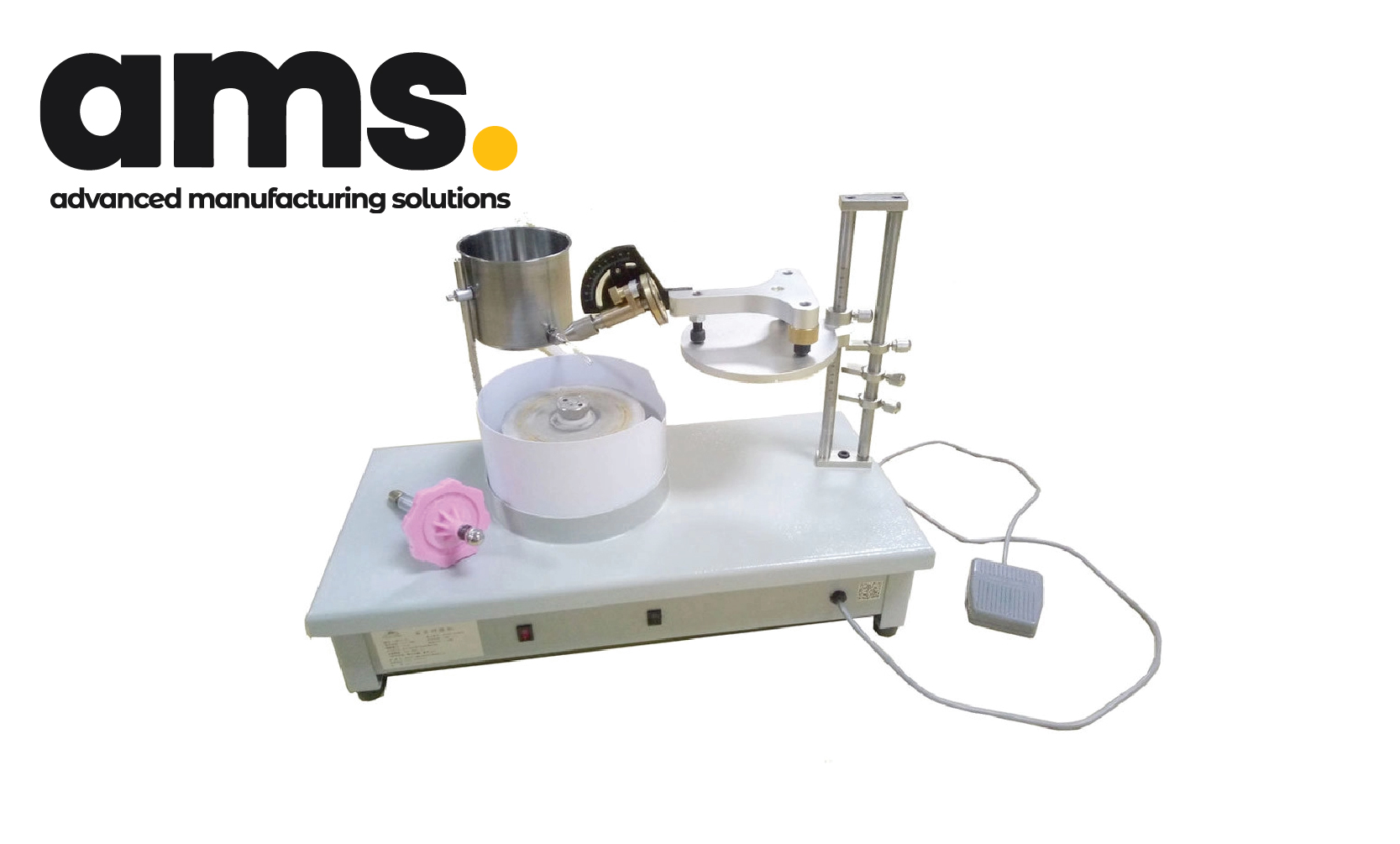

2. Polish Lapidary with diamond powder

When it comes to rough work for general purposes, it is common to use a fast handpiece equipped with a diamond bit to drill through hard materials such as rock. Once the drilling process is complete, the stone is polished using diamond paste or electrically charged compound on felt, wood or leather fittings. One of the most important aspects of rough polishing is choosing the right polishing compound. This decision depends on the material you are cutting, the hardness of the material, and whether the compound could damage the material.

There are two main types of polishing compounds: oil-soluble and water-soluble:

-

Water-soluble compounds work well on most materials, but they can rust your tools over time. Steel and water don't mix well, so even with careful use, steel shafts can rust.

-

Oil-soluble compounds, on the other hand, alleviate this problem and work especially well on difficult-to-polish materials such as rhyolite, ruby and sapphire, as well as stones with soft or hard areas. mixture. Oil-soluble compounds flow more easily on rock and are less likely to “stick,” which is a common problem with water-soluble compounds.

To begin the rough polishing process, a Class L Diamond Compound should be used. This requires the use of four specific micron grades, including 45 micron and 25 micron for shaping purposes, 14 micron for polishing. gloss and finally 1 micron to achieve a superior level of polish.

To use Diamond Compound, start by squirting the lubricant into a small dish and add a small amount of diamond compound to form a paste. Then, soak the pendulum or felt wheel in the mixture and gently work it over the surface of the stone. It is important to clean the stone with a detergent and a soft, clean brush each time the grinding stone is changed to avoid mixing coarse stones with finer stones and accidentally scratching the stone. Arranging the syringe, wheel, and pendulum according to their respective roughness is important for proper storage as it helps prevent cross-contamination and ensures longevity of the device.

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797