Norton Grinding Wheel

Grinding wheel is a product widely used in the mechanical field. Grinding is the final step before completing the product and plays an important role in product surface quality and production costs. If there are problems during the grinding process, it can be considered that the product does not meet the best quality when it reaches the user.

There are two types of grinding wheels commonly used in industry: Traditional grinding wheels and Alloy grinding wheels. Traditional grinding wheels are often made from traditional abrasives such as Aluminum Oxide, Silicon Carbide, Ceramic. Besides, alloy grinding wheels are often made from diamond/CBN particles.

In order to meet the needs and desires of providing customers with the best grinding stone products, Norton was born and met a variety of customers' needs in choosing grinding stones. Norton is a famous American grinding wheel manufacturer established in 1895.

Let's learn about some grinding wheel lines of the Norton brand with AMS!

1. Norton oil Grinding wheel

Norton oil grinding wheels is a line of grinding wheels with high sharpness and is trusted all over the world. This is the perfect combination of Aluminum Oxide, Silicon Carbide and exclusive adhesive developed by Norton.

Norton oil grinding wheels include the following types:

-

Crystolon Combination oil grinding wheel: the product is gray in color, has 1 rough surface and 1 smooth surface made of Silicon Carbide abrasive particles. The product is used for multi-purpose sharpening with a moderate amount of grinding residue, when the grinding time requirement is more important than the surface of the sharp edge.

-

India Combination oil grinding wheel: product is orange/gray in color, has 1 rough gray surface and 1 smooth orange surface. The product is made from aluminum oxide abrasives. This is a line of strong, long-lasting oil grinding wheels and excellent surface quality.

-

Crystolon/India combination oil grinding wheel: The stone consists of 1 rough, very sharp stone surface made of medium-fine Silicon Carbide abrasives (Crystolon) and 1 smooth surface made of aluminum oxide abrasives (India) for smooth surface. The rough stone surface is dark gray. The smooth stone surface is orange in color.

2. Norton Quantum hole grinding wheels

Norton Quantum hole grinding wheels are produced using the latest abrasive production technology: ceramic abrasives with a micro structure. With the application of high technology, the product helps the grinding process to be completed in the fastest time, saving costs, thereby maximizing the efficiency of the grinding process. The grinding wheels has the ability to self-sharpen, reducing the need to repair the grinding wheels, and is extremely durable, thereby extending the life of the stone.

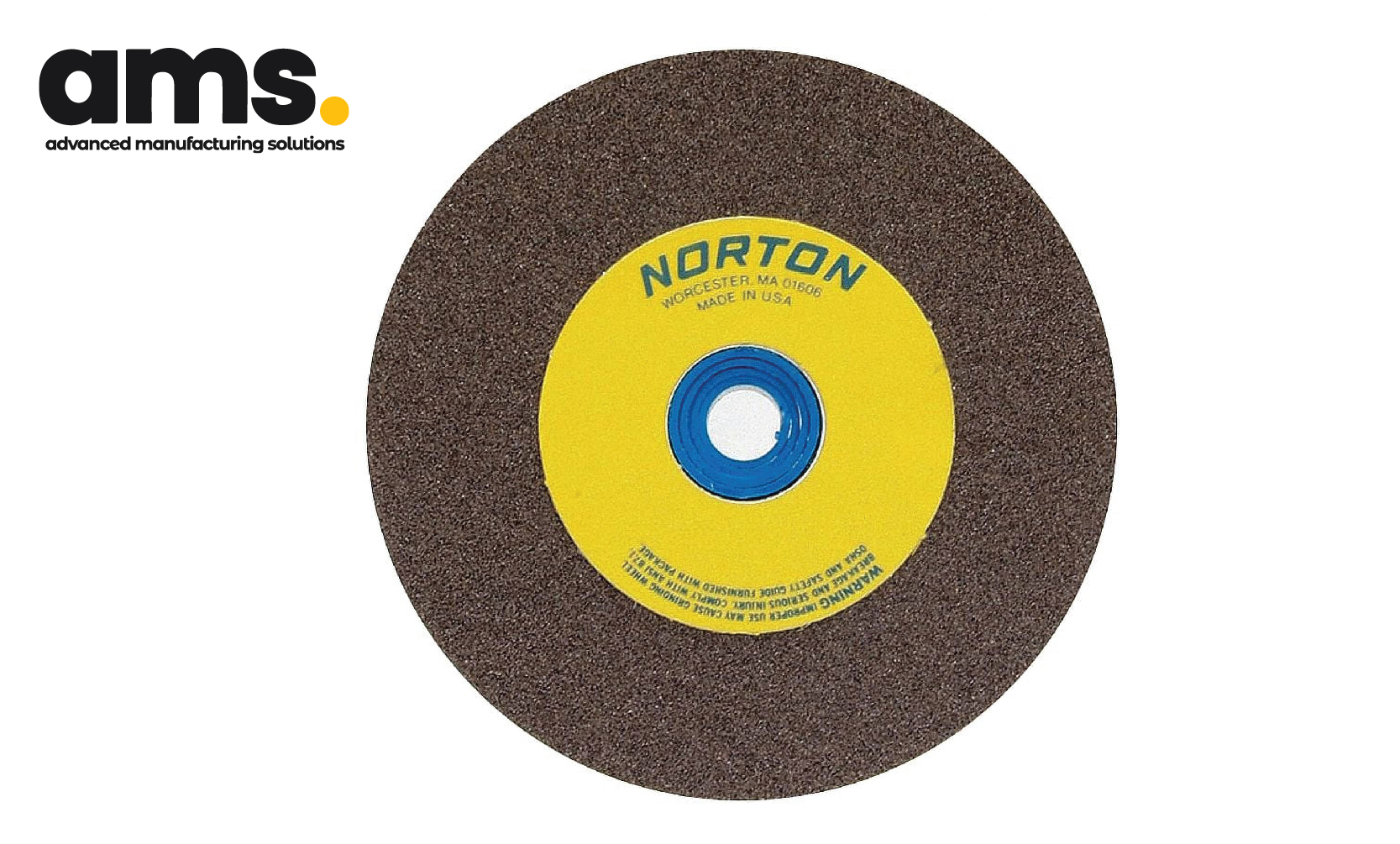

3. Norton A grinding wheels

Norton A grinding wheel is a line of grinding wheels produced from regular brown Aluminum Oxide grinding grains. Similar to Norton Quantum hole grinding wheel, Norton A grinding wheel has the ability to self-repair thanks to its microcrystalline structure, thereby increasing the life of the stone. With its durability, the product can be applied to steel and iron materials and is widely used in the grinding industry, mold industry, and maintenance rooms of large manufacturing plants. The product has durable and low-wear abrasive grains, suitable for application on 2-stone grinding machines.

Contact AMS now: If you need any assistance with grinding wheels, AMS is always happy to provide expert support. Our dedicated customer service team is ready to answer any questions you may have and provide personalized recommendations to take your manufacturing process to the next level.

Contact AMS today and let us become your trusted partner to improving your polishing abilities!

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797