HEIDENHAIN ECA 4000 Absolute Angle Encoder - Precision Redefined

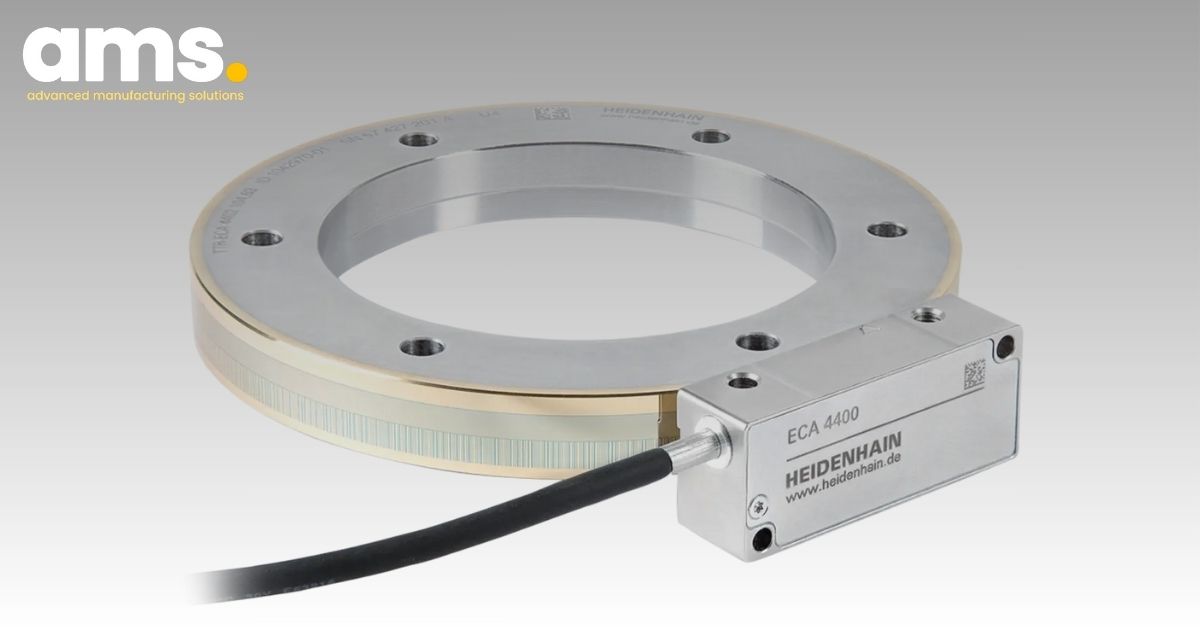

HEIDENHAIN has introduced the new ECA 4000 series of absolute angle encoders, designed for applications requiring precise angular measurement within a few angular seconds. These encoders support high rotational speeds and offer the flexibility of large hollow shaft diameters up to 512 mm. They are robust, providing high resolution and exceptional signal quality.

With the ECA 4000 series, there is no need for reference runs when using modular angle encoders. These encoders feature a steel scale drum with a dual axial graduation: a high-precision incremental graduation and an absolute graduation running along the circumference of the scale drum. The absolute data includes a high level of redundancy, while the incremental data is processed using a special ASIC in real time, resulting in immediately available high-resolution absolute position data upon switch-on.

Covering a wide range of applications from machine tools to metrology to the electronics industry, the ECA 4000 angle encoders have an inside drum diameter of 70 mm to 512 mm, making them suitable for direct drives and leading to significantly improved performance due to their signal quality.

Additionally, these angle encoders are largely mounting-compatible with known HEIDENHAIN ERA devices. The scale drums of both series are fully compatible, and in case of replacement, users only need to adjust the alignment of the scanning head, simplifying the process of converting existing equipment.

1. Reliable in machine tools

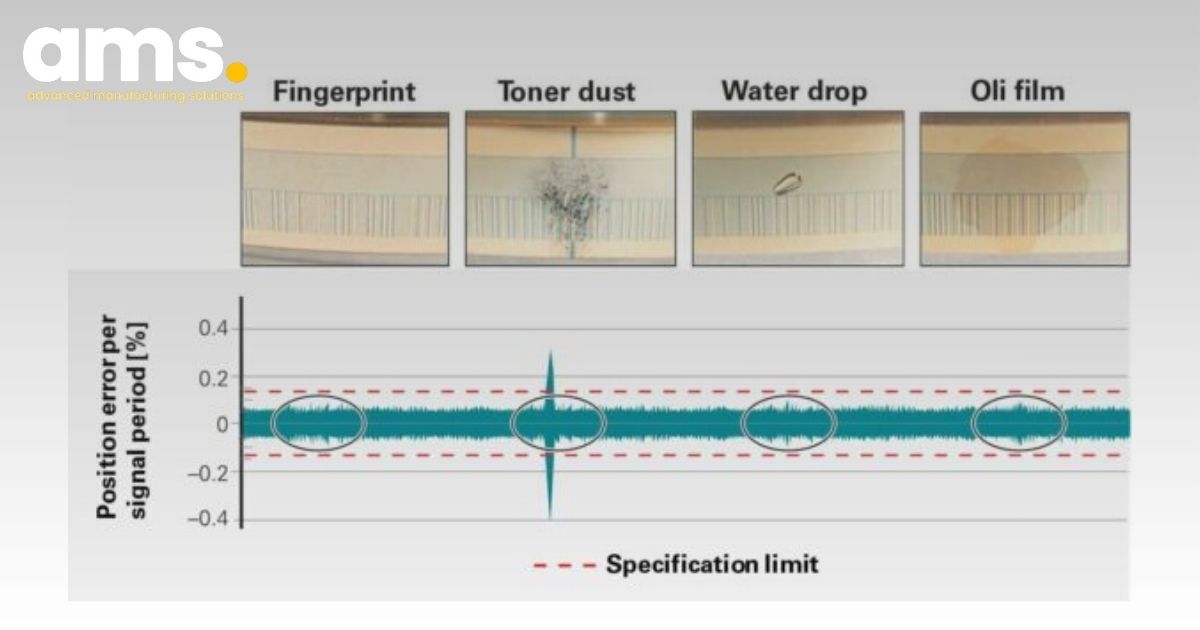

A high level of resilience and dependability is crucial for machine tool applications, which is why the ECA 4000 employs a scanning method with high contamination tolerance at its core. All electronic and optical components are housed together in a compact IP67-rated enclosure, while the external optical surfaces exhibit exceptional resistance to contamination. For example, the protective glass in the scanning head is easily cleanable and safeguarded from dust, dirt particles, and moisture, much like the robust and nearly planar METALLUR graduation on the scale drum. This makes the ECA 4000 angle encoders well-suited for use in machine tools such as rotary tables and swivel heads for milling, as well as high-precision, high-speed rotary axes for grinding and gear machining applications.

2. Precision advancements in electronics and metrology applications

In the electronics industry, there is a specific emphasis on achievable resolution and short-range deviation. The ECA 4000 achieves excellent values through single-field scanning and special optical filtering. Depending on the scale drum diameter, these absolute angle encoders produce position errors of only ±0.2 to ±0.04 angular seconds in one signal period.

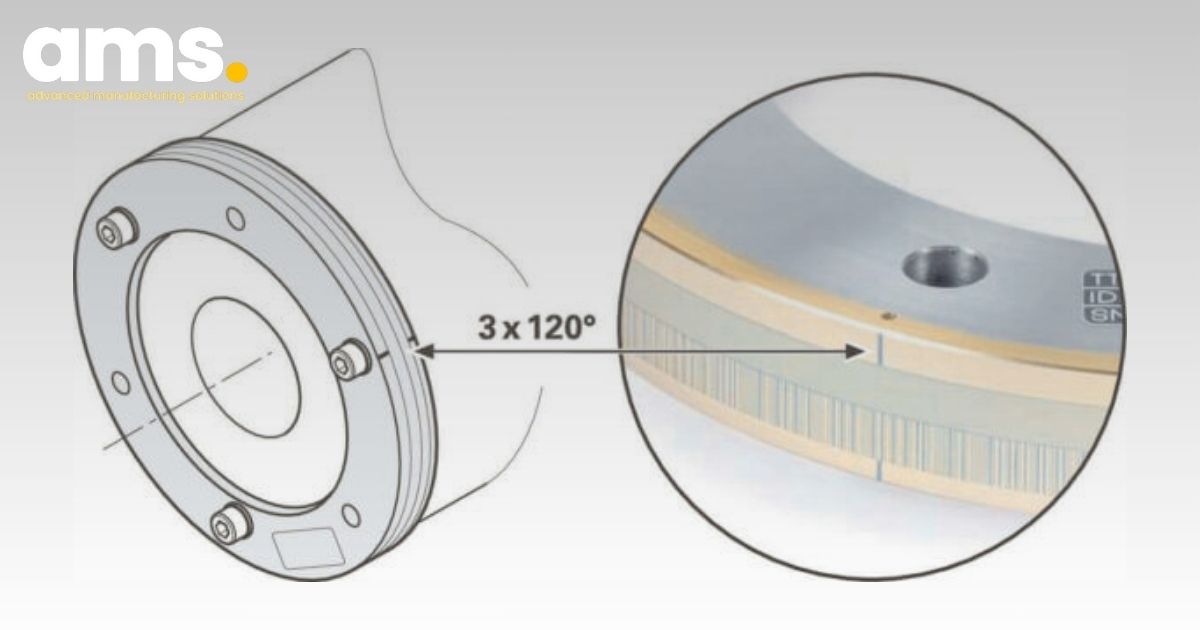

For metrology applications such as gear measurement, precision is a key expectation from an encoder. HEIDENHAIN addresses this by crafting the scale drum from steel and mounting it in a way that ensures the graduation accuracy of ±3 to ±1.5 angular seconds, depending on the diameter, remains unaffected by the mounting process.

3. Effortless and accurate encoder installation

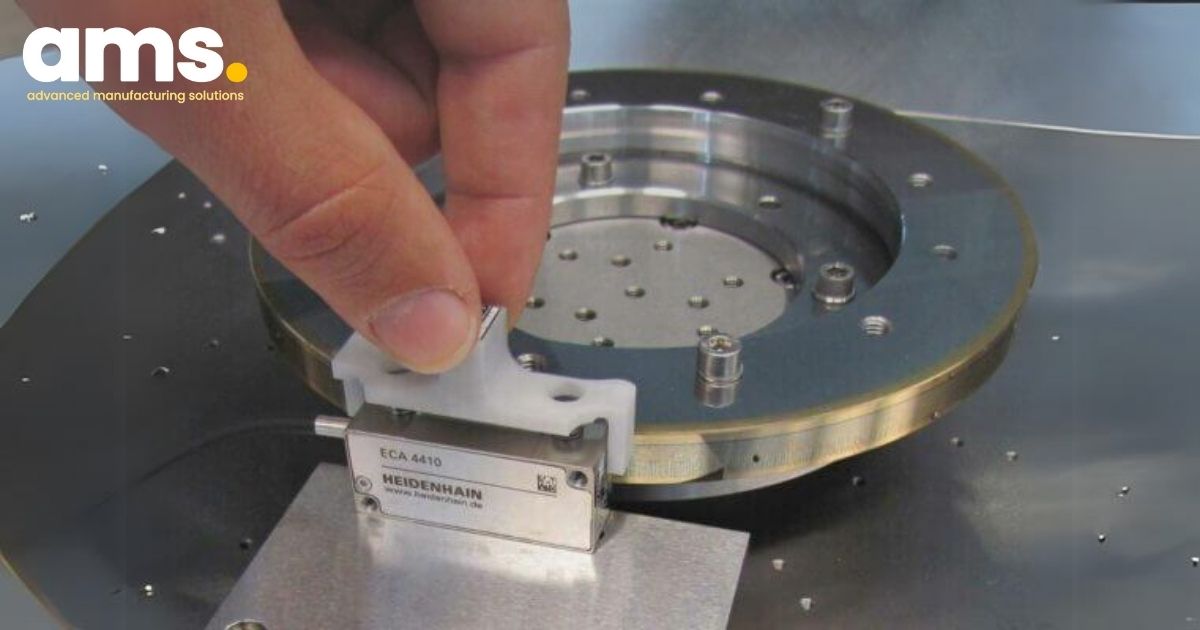

Minimizing eccentricity deviations is crucial for precision. The three-point centering method effectively reduces residual eccentricity and subsequent angular deviations, requiring minimal mounting requirements. After installing the scale drum, the scanning head is adjusted and mounted using a tool to set the spacing, simplifying the process with generous installation and operating tolerances. Unlike some angle encoders, fine adjustments such as setting the yaw or moiré angle are not necessary, as an integrated sensor recognizes and permanently compensates for deviation.

The large axial operating tolerance is particularly advantageous in certain applications, as a relative shift of ±0.4 mm about the central position between the scale drum and scanning head does not pose a problem. Additionally, users have the option to subsequently verify the installation of the ECA 4000 using the HEIDENHAIN PWM 20 phase angle measuring unit based on valuation numbers.

4. Simple commissioning

Utilizing the EnDat 2.2 bidirectional interface to connect the ECA 4000 angle encoder offers several advantages, including automatic commissioning. Through this interface, the encoder transmits all stored encoder-specific data such as resolution, interface data, and ID number to the subsequent electronics without requiring additional signal lines.

During operation, the EnDat interface allows for comprehensive monitoring and diagnosis of the encoder, enabling cyclic reading of valuation numbers that reflect its current condition and determine the performance reserve. This capability facilitates proactive maintenance planning and helps avoid unnecessary maintenance cycles, ultimately optimizing machine availability.

In addition to the EnDat interface, the ECA 4000 also supports the Fanuc and Mitsubishi interfaces, with support for Panasonic interfaces currently in the works.

5. HEIDENHAIN: Pioneering precision technology

HEIDENHAIN is a leading provider of advanced precision technology and expertise in the field, boasting a long-standing history of supplying top-tier measurement and control equipment. Established in 1889, the company has been instrumental in driving innovation and setting high industry standards in precision measurement and motion control. HEIDENHAIN's product range encompasses cutting-edge angular and linear encoders, digital readouts, and numerical controls, all engineered to deliver unparalleled accuracy and efficiency across diverse industrial applications.

In Vietnam, AMS Company Limited proudly serves as the exclusive distributor of HEIDENHAIN products. As a trusted partner, AMS offers comprehensive access to HEIDENHAIN solutions, ensuring customers in Vietnam have convenient and reliable access to top-quality products and services. Contacting AMS presents an opportunity for customers to benefit from competitive pricing and exceptional support, marking the first step towards harnessing HEIDENHAIN's outstanding precision solutions.

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797