5 Ways Heidenhain is Revolutionizing the Manufacturing Industry With Advanced Technologies and Sustainable Solutions

In today's highly competitive manufacturing industry, companies are under constant pressure to innovate and streamline their production processes to stay ahead of their competitors. One of the leading players in this domain is Heidenhain, a company well-known for offering state-of-the-art technology and automation solutions crucial to many manufacturers' success. AMS Company Limited, as the exclusive distributor of Heidenhain in Vietnam, plays an important role in providing these cutting-edge products and services to local businesses.

1. Advanced and Accurate Measurement Systems

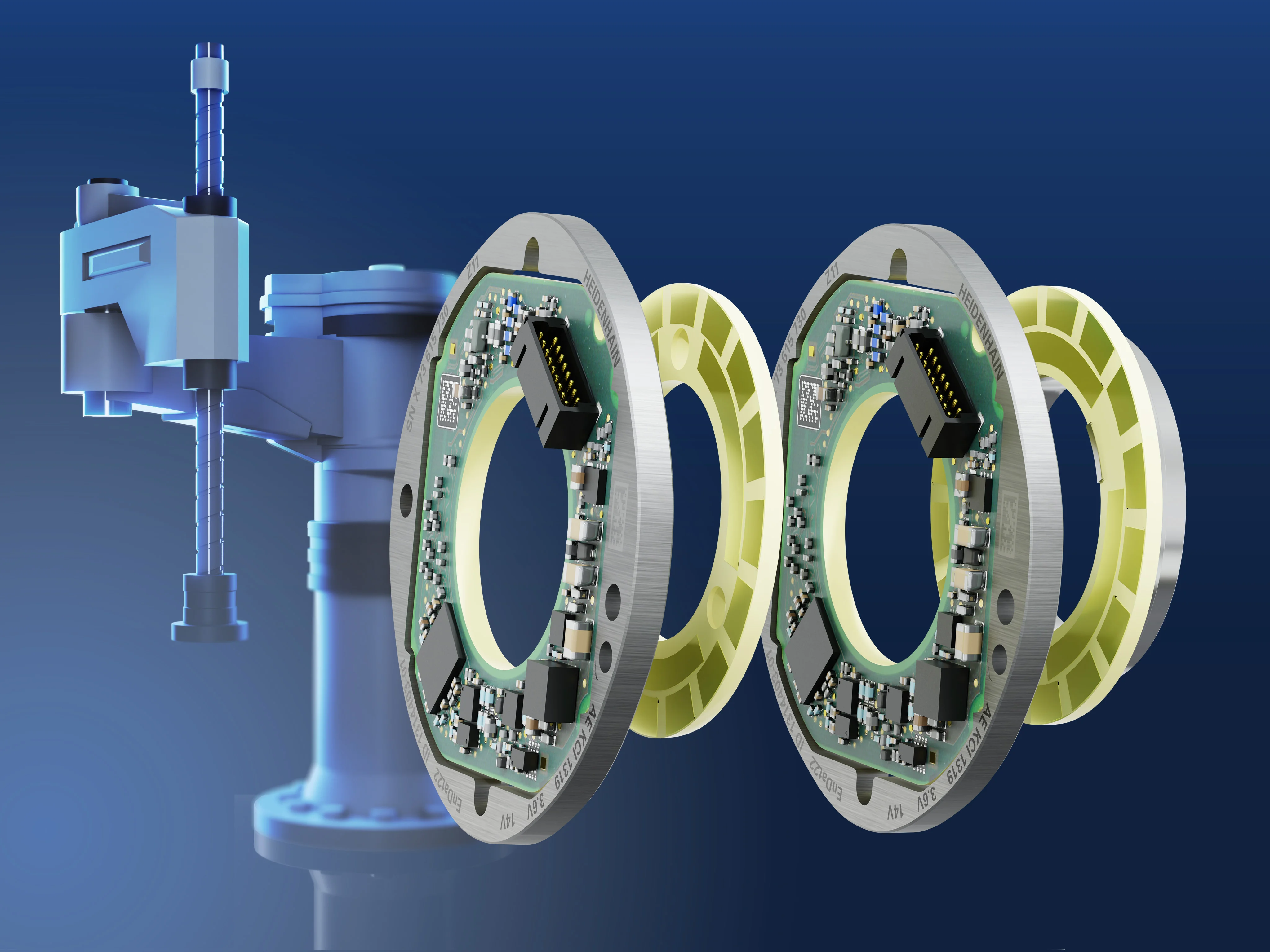

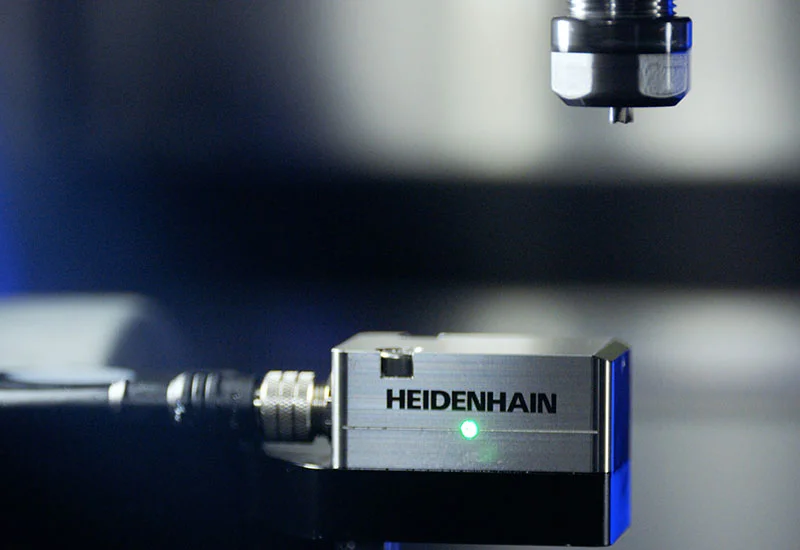

One of the keys to maintaining and improving production quality is the ability to accurately measure and monitor the manufacturing process. Heidenhain's innovative measurement systems have played a significant role in aspects of production. With the development of their high-precision linear scales, rotary encoders, digital readout systems, and touch probes, Heidenhain enables manufacturers to achieve unparalleled levels of accuracy and control in their machining processes.

These advanced measurement systems have direct applications in a variety of sectors such as aerospace, automotive, semiconductor, and medical engineering, allowing manufacturers to produce components that meet the most stringent quality and reliability requirements, while simultaneously staying lean and efficient in their production methods.

2. Enhanced CNC Machining Controls

Computer Numerical Control (CNC) technology is essential to modern manufacturing, as it enables the automation of complex machining processes. Heidenhain's CNC machining controls are among the most reliable versatile in the market, offering users the ability to optimize their production processes with ease. The TNC series of CNC controllers is designed to seamlessly integrate with CAD/CAM systems, and they provide advanced features such as 5-axis simultaneous machining, contouring control, dynamic error compensation, and tool management.

By incorporating Heidenhain's CNC controls into their production lines, manufacturers can achieve improved accuracy, shorter setup times, and reduced waste, leading to a more profitable and efficient operation. Consequently, this lays the groundwork for further automation and Industry 4.0 integration.

3. Innovation in Automation and Robotics

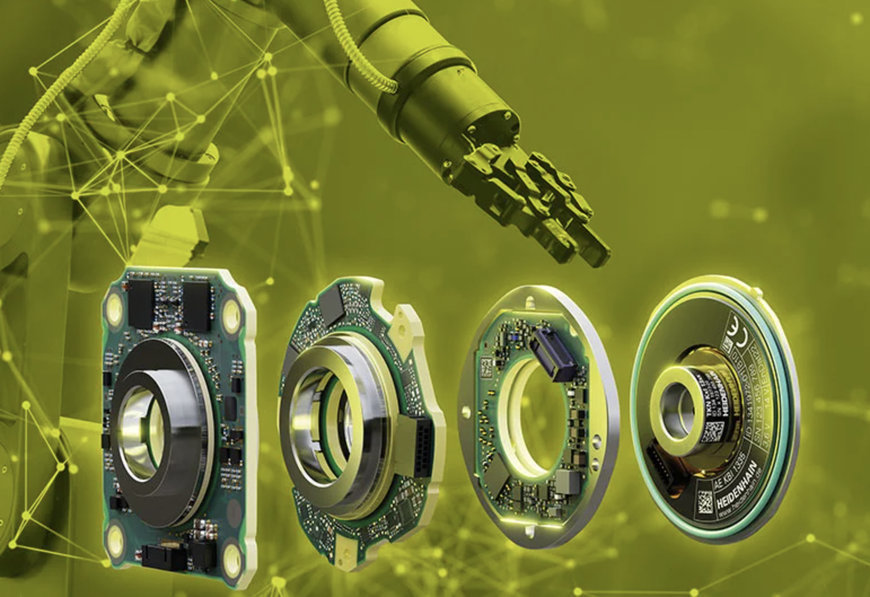

Heidenhain's focus on research and development has propelled them to the forefront of automation and robotics in the manufacturing industry. Their solutions allow manufacturers to automate their production processes and remove manual intervention, resulting in increased efficiency, worker safety, and productivity. Some of the most notable products include their motor-drive systems, position feedback systems for robotics applications, and specialized software solutions for Industry 4.0.

These sophisticated technologies not only serve to enhance productivity but also enable manufacturers to gain a competitive edge by incorporating cutting-edge robotics and automation solutions into their existing processes. As a result, manufacturers can continue to innovate and scale their businesses, while also meeting the demands of an increasingly interconnected global market.

4. Driving Industry 4.0 Integration

Heidenhain is at the forefront of enabling manufacturers to transition to Industry 4.0, thanks to their advanced technologies and commitment to innovation. By offering end-to-end solutions that integrate seamlessly into existing infrastructures, Heidenhain empowers manufacturers to embrace data-driven decision-making and real-time monitoring of the entire production process.

By leveraging Industry 4.0 capabilities such as the Internet of Things (IoT), Big Data analytics, and Artificial Intelligence (AI), Heidenhain's solutions allow manufacturers to optimize production processes, increase equipment efficiency, and minimize downtime. Through their cutting-edge technology, manufacturers can stay ahead of the competition and ensure the long-term success of their businesses.

5. Strong Commitment to Sustainability

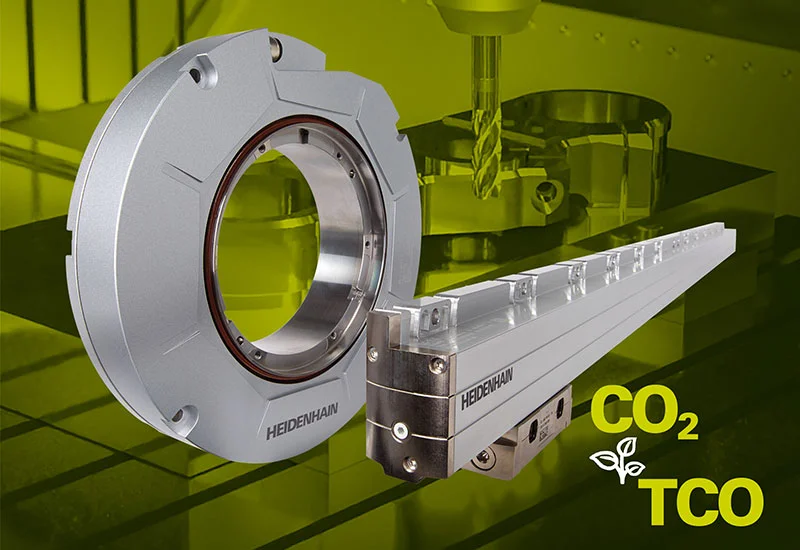

Heidenhain recognizes the importance of sustainability in the manufacturing industry, and their products and solutions are designed to help companies reduce their environmental impact. Their advanced precision measuring systems, for example, enable manufacturers to limit waste and increase efficiency, while the energy-efficient design of their CNC controllers and other automation products help reduce energy consumption.

By opting for Heidenhain's sustainable solutions, manufacturers can not only save costs and meet legal and regulatory standards but also work towards creating a more environmentally-friendly manufacturing industry for future generations.

6. Conclusion

Heidenhain has emerged as a leader in the manufacturing industry, thanks to their innovative solutions and commitment to driving progress. As a result, their advanced measurement systems, CNC controls, automation and robotics solutions, and sustainable practices have revolutionized the manufacturing world. The future of the industry lies in further embracing Industry 4.0 and smart manufacturing, and Heidenhain is undoubtedly playing a significant role in this transformation.

AMS Company Limited, the exclusive distributor of Heidenhain in Vietnam, is proud to bring these cutting-edge solutions to Vietnam manufacturers. Through their partnership with Heidenhain, AMS Company Limited is enabling local businesses to have access to high technology and gain a competitive edge in the global market.

By choosing Heidenhain's products and solutions, companies can enhance their competitiveness, streamline their processes, and ensure a prosperous future for their businesses, all while contributing to a more sustainable manufacturing industry. With the support of AMS Company Limited, Vietnam manufacturers are well-equipped to embrace the advantages provided by Heidenhain's innovative solutions as they progress toward achieving Industry 4.0 and smart manufacturing practices.

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797