Comparing HEIDENHAIN Inductive, Optical, and Magnetic Encoders: A Decision-Maker's Guide

Magnetic encoders utilize positive and negative poles, while optical encoders rely on light passing through a disc. Inductive encoders, however, employ charged coils that interact with a passive disc, modulating the sensor's received charges. Only a select few companies worldwide possess the expertise or technology to produce inductive encoders.

When there's no requirement for a high-end optical encoder, the conventional inclination is to turn to magnetic encoders. While this may often be the appropriate choice, overlooking inductive encoders as a viable option is a mistake. Inductive encoders present a viable middle ground in terms of capabilities and cost-effectiveness. It's important to compare the strengths and weaknesses of optical, inductive, and magnetic encoders to determine the most suitable application for each.

1. Key considerations for selecting which device is best

1.1. Common applications

If you require utmost precision or need to facilitate highly dynamic motion, optical encoders are the optimal choice due to their consistent accuracy and resolution. These are well-suited for applications such as pick-and-place robots, telescopes, antennas, and machine tool operations including CNC lathes and mills.

Magnetic encoders are suitable for projects requiring multiple installations of the same type of encoder, such as in mining operations where high vibration levels and debris pose challenges.

Inductive encoders offer a blend of contamination and vibration resistance akin to magnetic encoders, along with enhanced accuracy approaching the level of optical solutions. They are well-suited for general automation systems, various types of servo motors, medical equipment like CT scanners, and the robotics industry.

1.2. Environmental factors

The installation environment and surrounding conditions are key factors to consider when choosing encoders. Optical encoders are most effective in cleaner environments due to their scanning method; however, various mounting and sealing options can be utilized to maintain their cleanliness in other environments.

Magnetic encoders excel in environments with high vibration levels exceeding 30-40 Gs and heavy contamination. It's important to note that the internal magnets of magnetic encoders can be affected by nearby magnetic brakes, impacting the generated signal.

Inductive encoders are unaffected by magnetic fields and can withstand high levels of vibration and contamination, while also providing greater accuracy than magnetic solutions. The primary challenge with inductive encoders lies in ensuring consistent proximity between the sensor and rotor throughout the application's operation.

1.3. The biggest advantages

When you’re looking for the “best solution,” start with optical encoders. Their accuracy, repeatability and resolution capabilities are unmatched. They are the most common solution and have many variations to fit the needs of multiple applications. That said, if you have a higher accuracy requirement, but the application does experience high vibration or contamination, the best solution may be an inductive option.

If a low-cost solution is the goal, magnetic encoders are a good place to start. They’re compact enough to fit in tight spaces and they’re fairly inexpensive.

Inductive encoders are a kind of Goldilocks solution: not the most accurate, but enough for most applications, while also able to withstand various different environments and situations.

Sure, inductive encoders are a little more difficult to understand, but their above-average accuracy paired with above-average resilience make them the ideal choice—for a number of applications.

In 2015 HEIDENHAIN acquired AMO, arguably combining the two most successful makers of inductive encoders.

2. Exploring HEIDENHAIN inductive, optical, and magnetic encoder options

HEIDENHAIN is renowned for its high-quality encoders, offering a comprehensive range of inductive, optical, and magnetic solutions designed to meet diverse industrial needs. Let's delve into each type of encoder and explore some noteworthy examples from HEIDENHAIN's lineup.

2.1. HEIDENHAIN Inductive Encoders

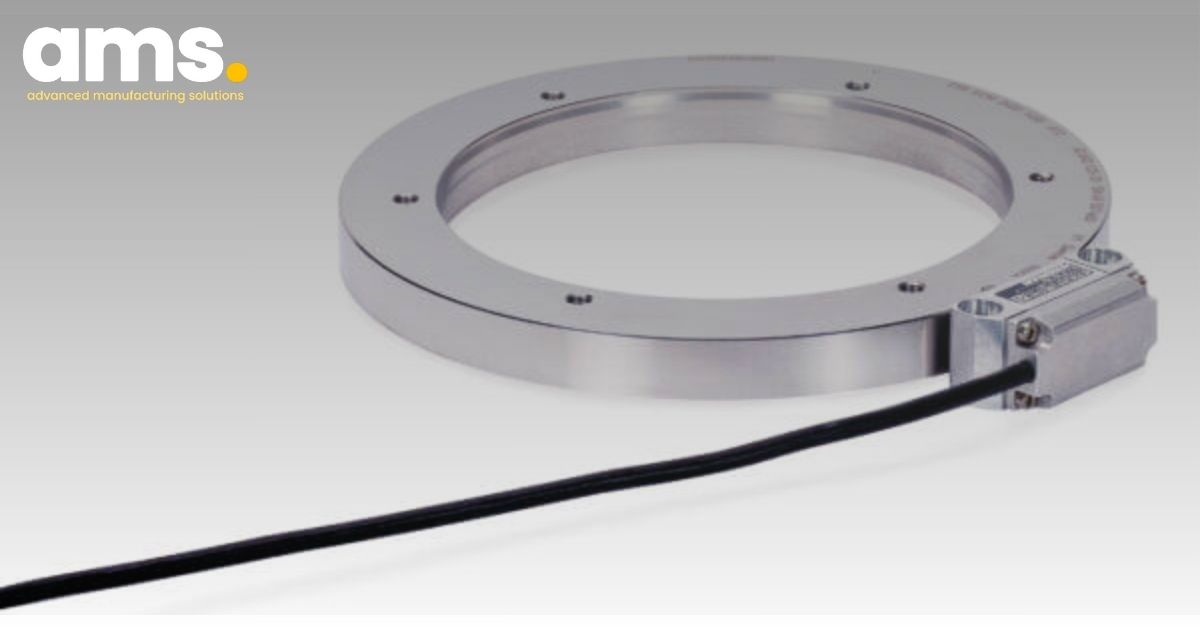

HEIDENHAIN's inductive encoders are celebrated for their reliability and precision, making them an ideal choice for applications where resilience and accuracy are paramount. These encoders excel in environments with high levels of vibration and contamination, offering enhanced accuracy comparable to optical solutions. Notable examples of HEIDENHAIN inductive encoders include the ECI 1118, ECI 119, and ECI 1300 series, which are well-suited for general automation systems, servo motors, medical equipment such as CT scanners, and robotics applications.

2.2. HEIDENHAIN Optical Encoders

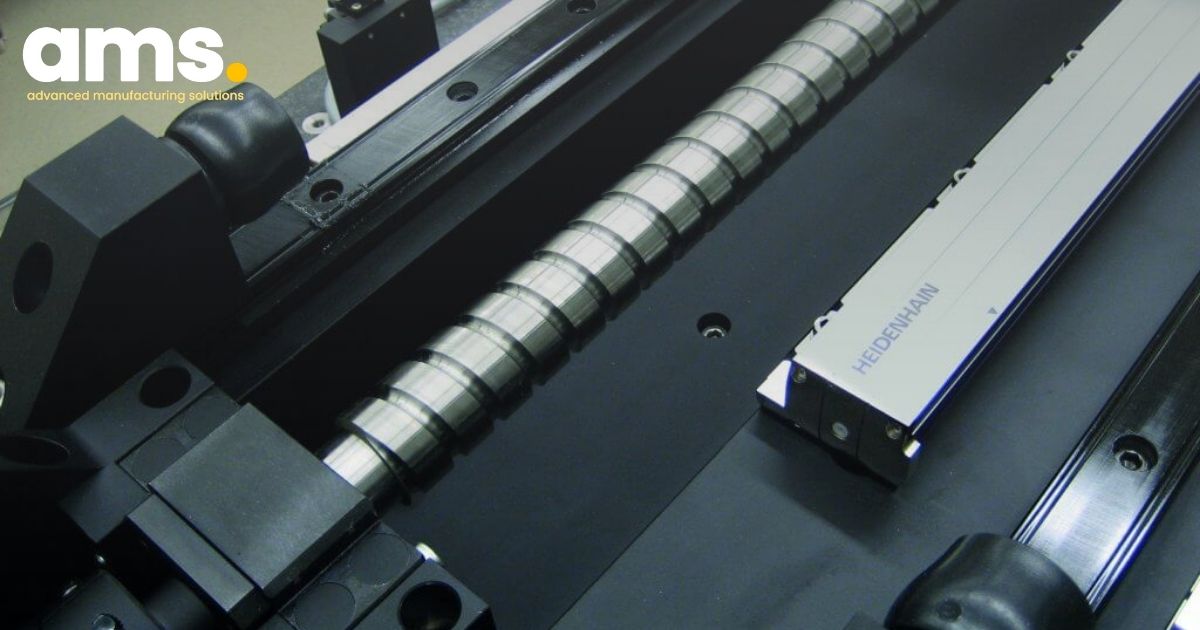

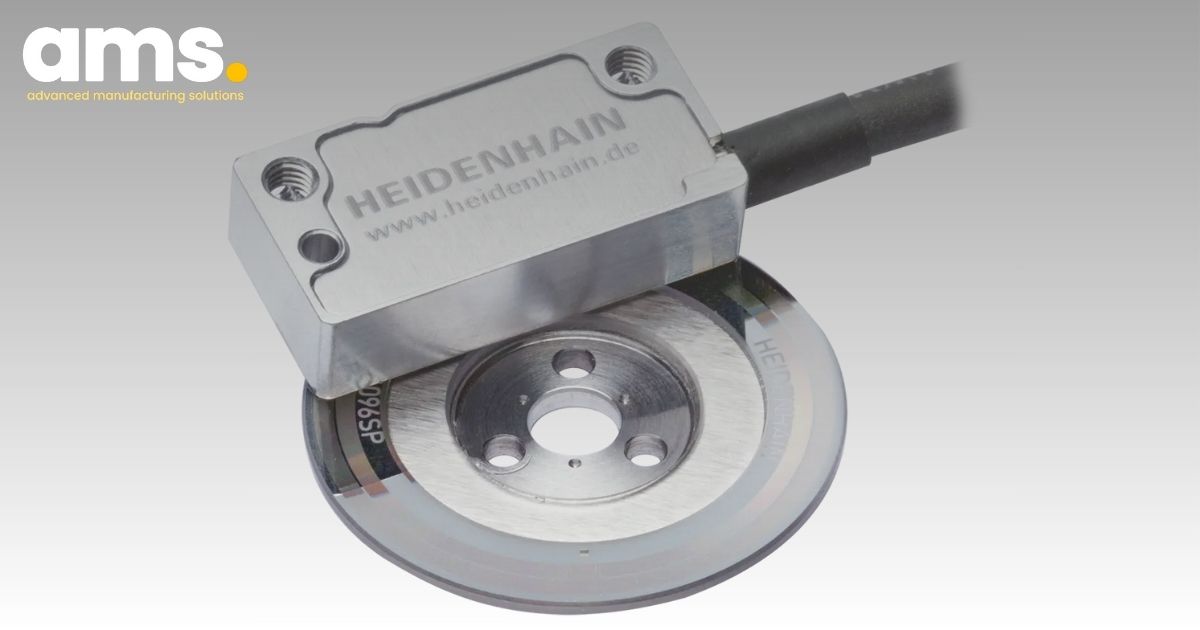

When it comes to uncompromising accuracy, repeatability, and resolution, HEIDENHAIN's optical encoders stand out as the premier choice. These encoders are highly versatile, with a wide range of variations tailored to suit specific application requirements. Examples of HEIDENHAIN optical encoders include the well-regarded ERO, EQN, and ECN series, which find applications in pick-and-place robots, telescopes, antennas, CNC machine tools, and other precision-driven systems.

2.3. HEIDENHAIN Magnetic Encoders

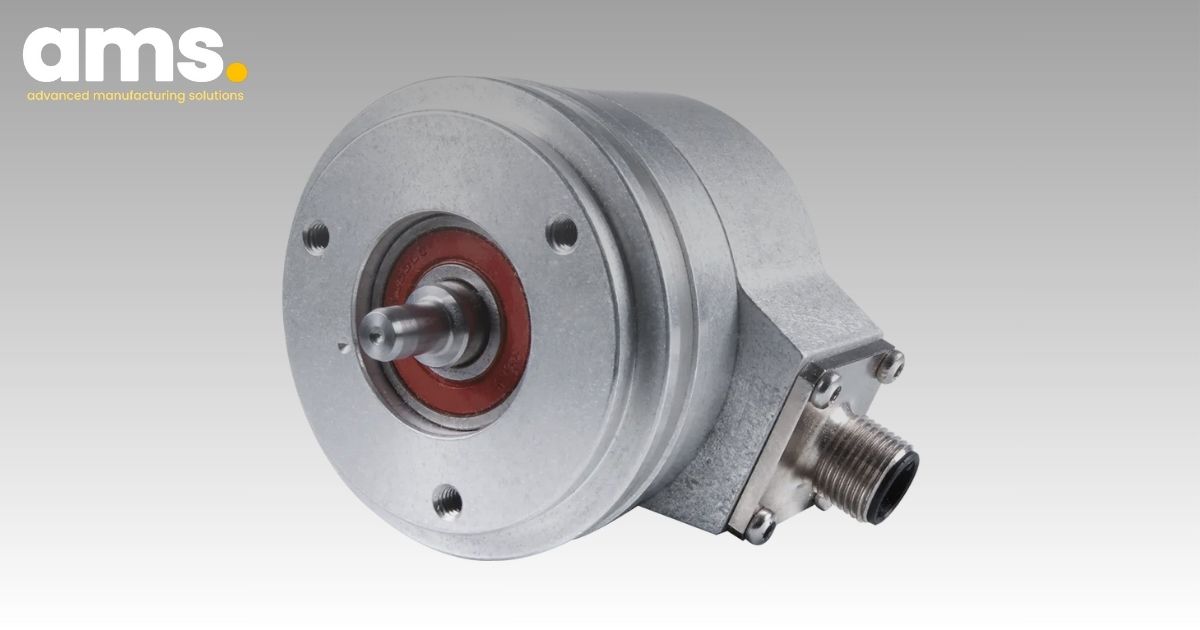

For cost-effective and compact encoder solutions, HEIDENHAIN's magnetic encoders offer a compelling option. These encoders are well-suited for applications where multiple installations of the same type of encoder are needed, such as in mining operations where high vibration levels and contamination are prevalent. Notable examples of HEIDENHAIN magnetic encoders include the ROC, RCN, and EQI series, designed to thrive in demanding industrial environments while delivering reliable performance.

3. AMS Company Limited - Exclusive Distributor of HEIDENHAIN in Vietnam

AMS Company Limited proudly holds the exclusive distribution rights for HEIDENHAIN products in Vietnam. HEIDENHAIN, a respected provider of precision measurement and control equipment, is known for the quality and reliability of its offerings. Partnering with us provides access to a diverse selection of HEIDENHAIN encoders suitable for various industrial purposes.

Consult AMS Company Limited for expert advice on selecting the right HEIDENHAIN encoder tailored to your specific business requirements. Our team of seasoned professionals is dedicated to understanding your needs and recommending optimal solutions to streamline your operations. Whether your industry focus is automotive, aerospace, medical, or general manufacturing, we are equipped to assist you in choosing the ideal HEIDENHAIN encoder for your applications.

When you source HEIDENHAIN products through AMS, you benefit from HEIDENHAIN's comprehensive warranty and maintenance policy. This guarantees that the products we supply are covered under HEIDENHAIN's warranty, providing assurance regarding the longevity and performance of your investment. On the contrary, purchasing products from alternative sources may lack the safeguard of being covered by HEIDENHAIN's warranty and maintenance policy. In case of malfunctions or unforeseen issues, this disparity could lead to added expenses and disruptions to your operations.

Count on AMS Company Limited as your exclusive partner in Vietnam to acquire authentic HEIDENHAIN products supported by dependable warranty and maintenance services. Get in touch today to explore our range of HEIDENHAIN encoders and enjoy the peace of mind that comes with collaborating with the premier distributor in the region.

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797