Superabrasives vs. Conventional Abrasives: 5-step guide to choose the right Norton abrasive

Selecting the appropriate abrasive material essential in achieving optimal results for grinding and finishing tasks in industrial applications. Two main types of abrasives are typically used in the industry: conventional abrasives and super abrasives. Conventional abrasives, such as aluminum oxide and silicon carbide, have been around for decades and are widely used in various metalworking applications. On the other hand, super abrasives, such as diamond and cubic boron nitride (CBN), have gained popularity in recent years due to their exceptional hardness, heat resistance, and durability.

As a leading manufacturer of high-quality abrasives, Norton has made significant strides in developing super abrasive products that offer superior performance and efficiency compared to conventional abrasives.

1. What are Superabrasives?

Super abrasives are a class of abrasives that are significantly harder and more durable than conventional abrasives. They are typically made of diamond or CBN and are used in a variety of high-precision grinding and finishing applications. Super abrasives offer a range of benefits, including:

1.1. Hardness

Super abrasives are the hardest materials known to man, making them ideal for applications that require high precision and durability.

1.2. Heat resistance

Super abrasives can withstand high temperatures, reducing the risk of thermal damage during grinding and polishing operations.

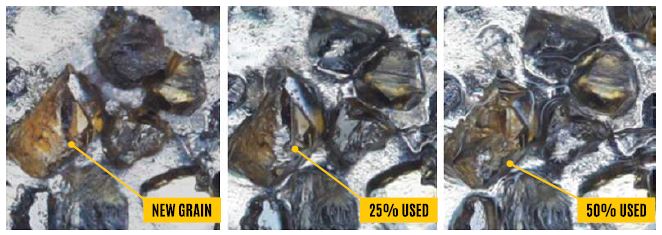

1.3. Longevity

Super abrasives last much longer than conventional abrasives, reducing the need for frequent replacements and downtime.

2. What are Conventional Abrasives?

Conventional abrasives, such as aluminum oxide and silicon carbide, have been around for decades and are commonly used in various industrial applications. Conventional abrasives offer a range of benefits, including:

2.1. Affordability

Conventional abrasives are typically less expensive than super abrasives, making them a more budget-friendly option for many industrial applications.

2.2. Versatility

Conventional abrasives can be used in a wide range of applications, making them a popular choice for many metalworking operations.

3. How Norton Abrasives is Revolutionizing the Industry

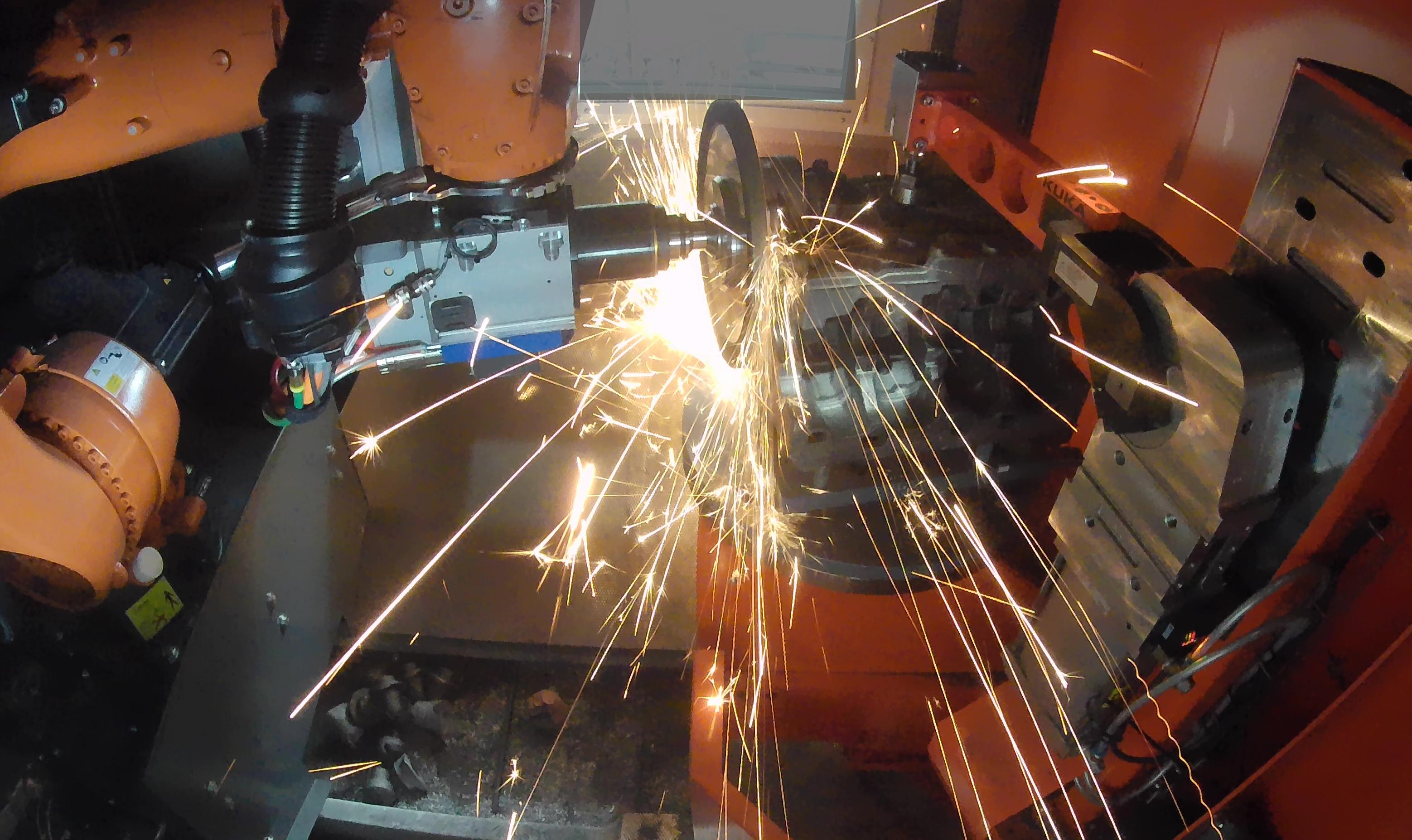

Norton has been at the forefront of developing super abrasive products that offer superior performance and efficiency compared to conventional abrasives. The company uses advanced manufacturing techniques and materials to create super abrasive products that deliver exceptional precision, durability, and longevity. Norton's super abrasive products are used in a wide range of applications, including aerospace, automotive, medical equipment, and precision machining.

One of Norton's latest innovations is the Norton Winter Paradigm Diamond Wheels, which use advanced bond technology and a unique diamond grain shape to increase efficiency and reduce grinding time. These wheels have been shown to outperform conventional diamond wheels by up to 30% and reduce cycle times by up to 50%. Additionally, Norton's Vitrium3 technology uses advanced bond chemistries and manufacturing techniques to create grinding wheels that deliver long-lasting performance and minimal dressing requirements.

4. Five essential steps for choosing the right Norton Abrasive products for your applications

Selecting the right abrasive products is essential for optimizing performance, reducing production costs, and achieving the best results.

4.1. Identify Your Application Needs

Before you start selecting an abrasive product, it's essential to identify your application needs. Consider the material you're grinding or finishing, the type of operation, required finish quality, and tolerances. Different applications require different abrasive properties such as abrasion resistance, heat resistance, and cutting ability. Understanding your application needs will help you choose the right abrasive product that meets your requirements.

4.2. Choose the Right Abrasive Type

Norton offers a range of abrasive products, including bonded abrasives, coated abrasives, super abrasives, and diamond abrasive products. The type of abrasive product you choose depends on your application needs. For instance, super abrasives, such as diamond and cubic boron nitride (CBN), are ideal for high-precision applications that require exceptional hardness, heat resistance, and long life. On the other hand, coated abrasives, such as sanding belts and discs, are ideal for surface preparation, blending, sanding, and polishing.

4.3. Select the Right Coating and Bonding

The coating and bonding play a crucial role in determining the abrasive product's performance, durability, and efficiency. Norton offers a range of coatings and bondings, including vitrified, resin, metal, and electroplated bonding. Each bonding type has its pros and cons, and selecting the right bonding for your application is crucial. For instance,rified bonded abrasives are ideal for precision grinding and are known for their exceptional wear resistance and stability.

4.4. Choose the Right Shape

Norton offers a range of abrasive shapes, including wheels, discs, belts, cones, and mounted points. The shape you choose depends on your application needs. For instance, grinding wheels are ideal for removing large amounts of material quickly, while mounted points are ideal for detailed work and hard-to-reach areas.

4.5. Take Safety Precautions

When selecting abrasive products, safety should always be a top priority. Norton offers a range of safety products and recommendations to ensure that your grinding and finishing operations are safe. It's essential to read the manufacturer's safety recommendations and guidelines to ensure that you're using the abrasive products correctly and safely.

Norton offers a diverse range of high-quality abrasive products to cater to the different needs of various industries. By following these steps, you can choose the right abrasive product that matches your application needs, ensuring optimal performance, efficiency, and safety.

5. Conclusion

If you're still unsure about which Norton abrasive product is right for your specific application needs, contact AMS Company Limited. As an authorized distributor of Norton products, AMS Company Limited's team of experts can help you choose the right abrasive product that matches your needs and specifications. Our professionals will provide you with the guidance and support necessary to implement cost-effective manufacturing solutions that will improve your productivity and reduce your production costs. Contact AMS Company Limited today to learn how we can help you optimize your grinding and finishing operations.

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797