5 Pros and Cons of using Diamond Slurries and CBN Slurries

Diamond slurries and CBN slurries are widely used in various industries, particularly in materials processing and polishing applications. Both slurries offer unique advantages and disadvantages. This article aims to delve into the five key pros and cons of using diamond slurries and CBN slurries, shedding light on their suitability for different purposes.

1. What are Diamond slurries and CBN slurries, suspensions, and compounds?

Diamond and cubic boron nitride (CBN) slurries, suspensions, and compounds are a cutting-edge solution for achieving impeccable surface quality. They're made up of tiny diamond and CBN particles that are suspended in a liquid or oil base. Suspensions, and compounds are a game-changer in the world of lapping and polishing. These innovative substances pack a powerful punch when it comes to achieving that coveted mirror-like finish on moulds.

So, what exactly are diamond slurries? Well, as the name suggests, they consist of tiny diamond particles suspended in a liquid medium. These slurries act as an abrasive agent that helps to remove surface imperfections and create a smooth surface. On the other hand, CBN slurries contain cubic boron nitride particles – another super-hard material known for its exceptional cutting capabilities.

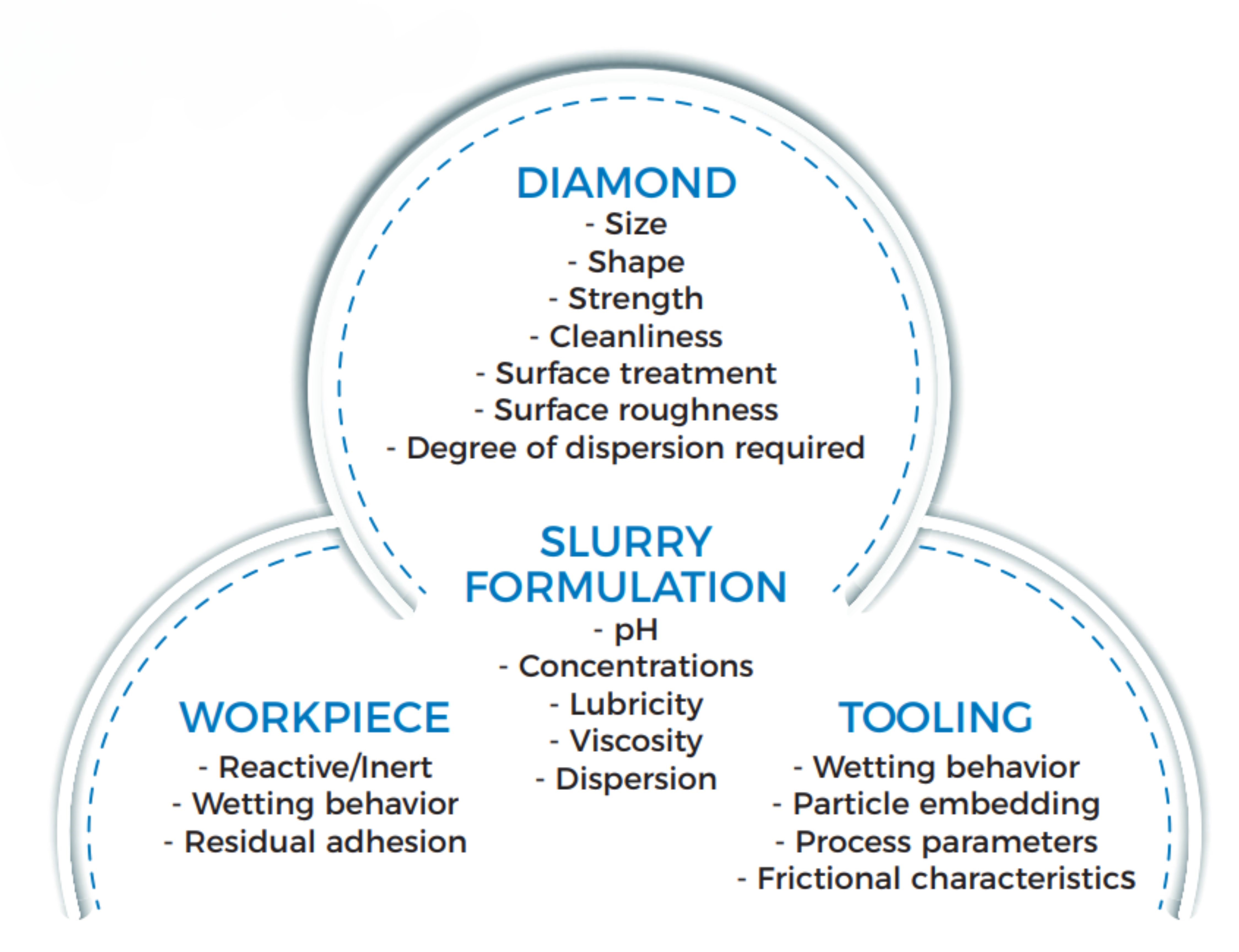

Both diamond and CBN slurries are available in various concentrations or grit sizes. The choice depends on the specific application requirements – finer grits for achieving high levels of precision or coarser grits for faster material removal.

In addition to slurries, there are also suspensions available. Suspensions have larger particle sizes compared to slurries but offer similar benefits in terms of smoothing out surfaces. They can be used with different types of polishing pads or cloths to achieve desired results.

We have compounds that typically come in paste form mixed with a carrier such as an oil or water-based solution. Compounds work by combining an abrasive material like diamond or CBN with lubricants and binders that aid in the polishing process.

Now that we've understood what these magical substances are made up of let's explore how they work their magic!

2. How do Diamond slurries and CBN slurries, suspensions, and compounds work?

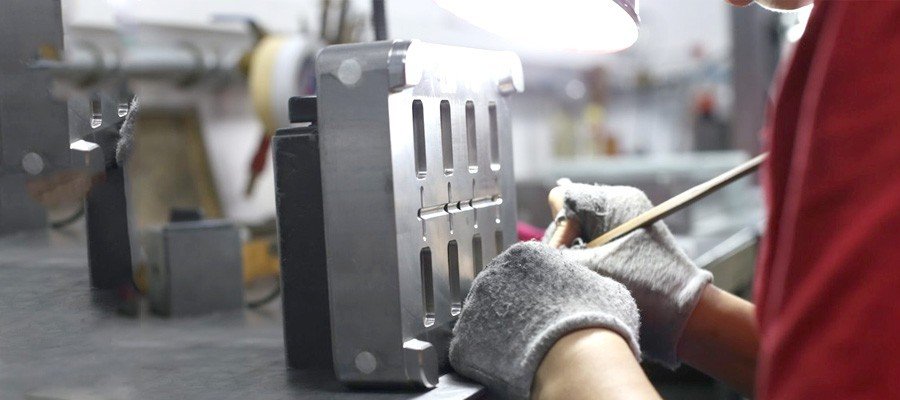

Diamond and cubic boron nitride (CBN) slurries, suspensions, and compounds are widely used in the field of lapping and polishing to achieve high-quality finishes on various materials. These abrasive substances work by utilizing their exceptional hardness to remove surface imperfections and enhance the overall smoothness of material.

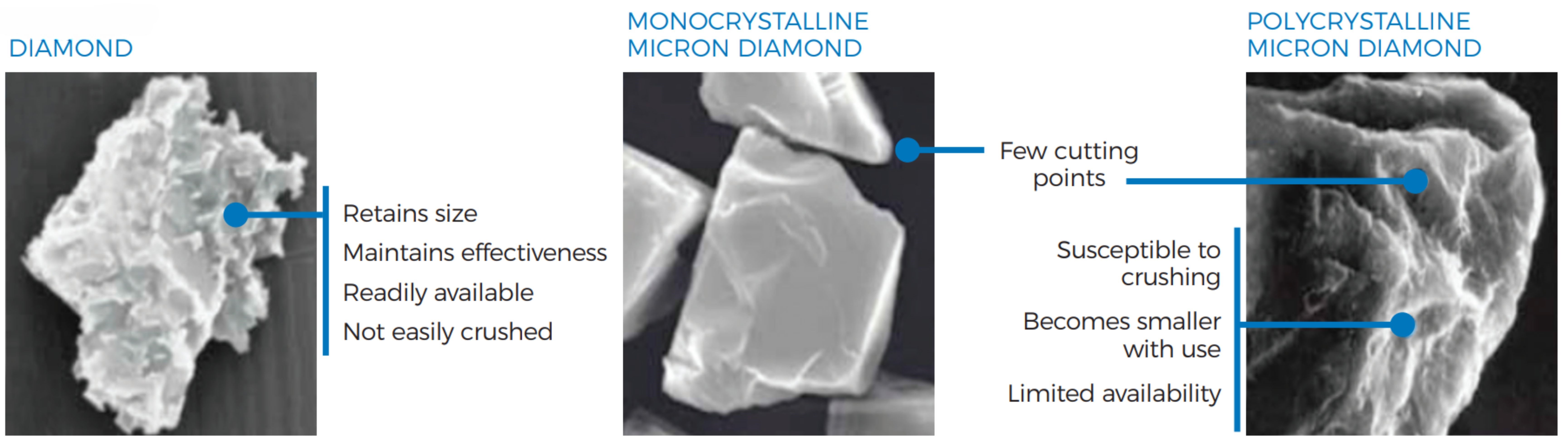

When it comes to diamond slurries, they consist of tiny particles of synthetic diamond suspended in a liquid medium. The hardness of diamonds allows them to effectively abrade the material being polished, resulting in a highly refined surface finish. Diamond slurries are commonly used for precision polishing applications on hard materials such as metals, ceramics, and glass.

On the other hand, CBN slurries utilize fine particles of cubic boron nitride suspended in a similar liquid medium. Cubic boron nitride is known for its exceptional thermal stability and hardness comparable to that of diamonds. This makes CBN slurries ideal for polishing applications involving ferrous metals like steel or cast iron.

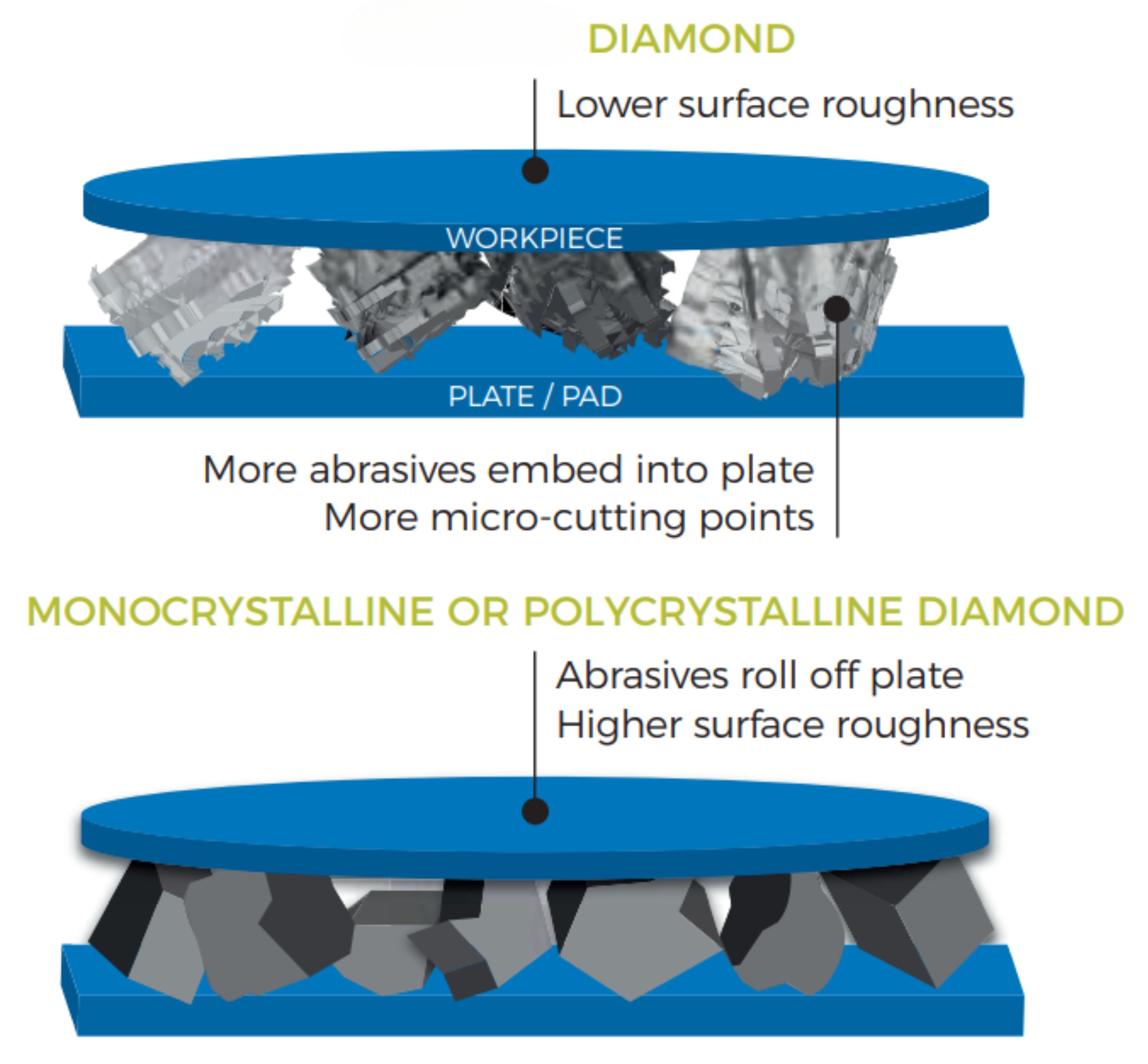

Both diamond and CBN suspensions work by evenly distributing the abrasive particles across the surface being worked upon. As pressure is applied during lapping or polishing, these hard particles gradually wear down any roughness or irregularities present on the material's surface. The result is a smoother finish with improved flatness and dimension accuracy.

In addition to slurries, there are also diamond and CBN compounds available that come in paste form containing larger sized abrasive particles embedded within greases or oils. These compounds provide more aggressive cutting action compared to slurries but may require additional steps for final finishing.

Diamond and CBN slurries, suspensions, and compounds offer excellent performance when it comes to achieving precise finishes on various materials. Their ability to remove imperfections while maintaining dimensional accuracy makes them indispensable tools in industries such as automotive manufacturing, electronics production,and mold making.

3. Pros of using Diamond slurries and CBN slurries, suspensions, and compounds

Diamond slurries and cubic boron nitride (CBN) slurries, suspensions, and compounds offer numerous advantages when it comes to lapping and polishing. Let's explore some of the pros of using these abrasive materials

- Exceptional hardness: Diamonds are renowned for being the hardest known substance on Earth, while CBN closely follows in second place. This hardness allows them to effectively abrade a wide variety of materials with precision and consistency.

- Superior thermal conductivity: Diamond and CBN have excellent heat dissipation properties, which means that they can withstand high temperatures during the lapping or polishing process without undergoing significant degradation. This makes them ideal for applications where heat generation is a concern.

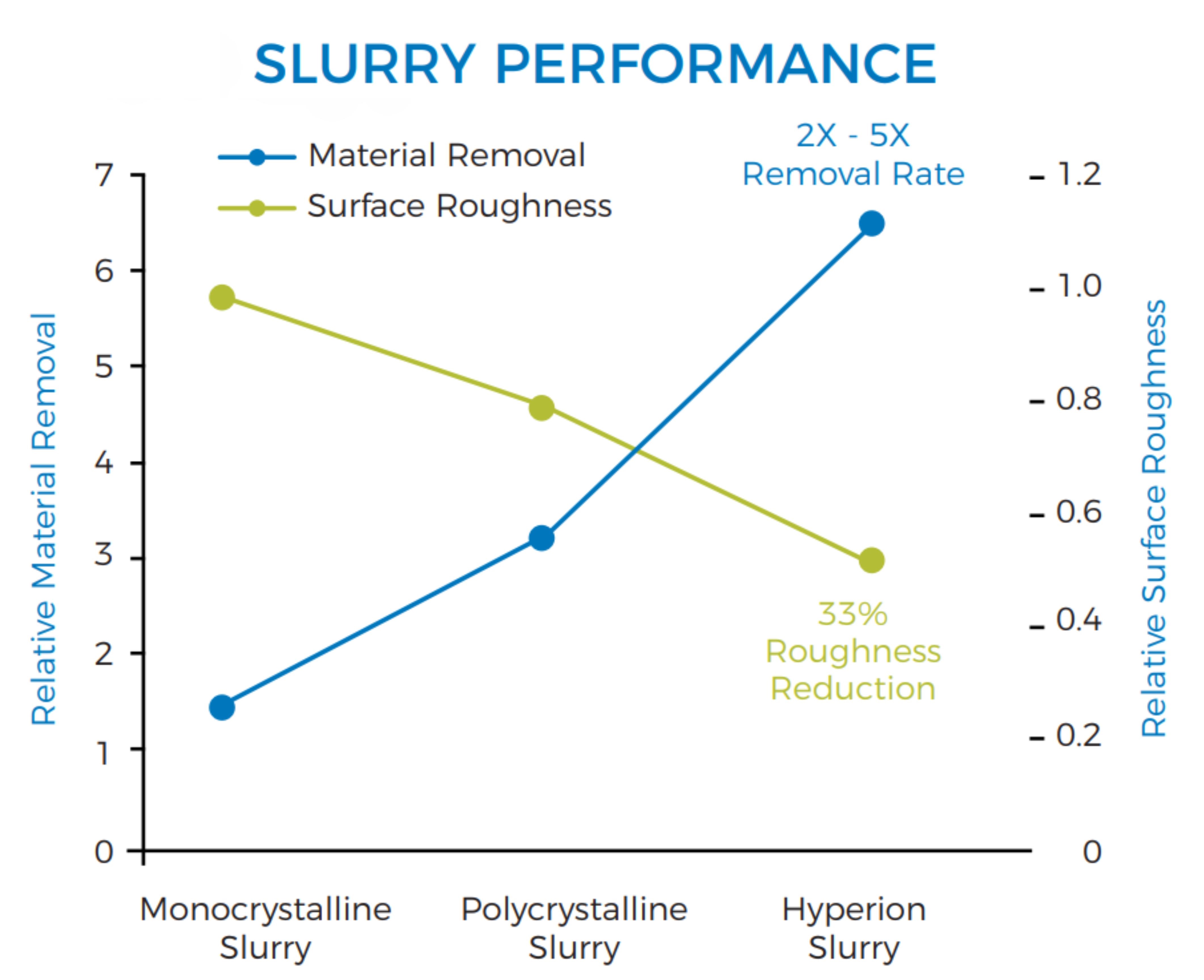

- Excellent cutting properties: They have sharp edges that can easily remove material from the workpiece surface, resulting in faster stock removal rates compared to other abrasives. Additionally, this efficient cutting action helps achieve smooth finishes with minimal surface damage.

- Wear resistance: Their durability ensures longevity even under demanding conditions or prolonged use. This feature translates into cost savings as less frequent replacement or replenishment is required.

- Compatibility with various substrates: Depending on specific requirements, there are different variations available such as water-based or oil-based formulations allowing users flexibility when selecting a suitable slurry or suspension for their application needs.

4. Cons of using Diamond and CBN slurries, suspensions, and compounds

While Diamond and cubic boron nitride slurries, suspensions, and compounds offer numerous advantages for lapping and polishing processes, there are also some drawbacks that need to be considered. Here are a few cons to keep in mind:

- Cost: One significant disadvantage of using diamond slurries or cubic boron nitride compounds is their relatively high cost compared to other abrasives. These materials can be expensive, especially when used in large quantities or for extensive polishing projects.

- Environmental impact: The production of diamond and cubic boron nitride abrasives involves mining natural resources, which can have environmental consequences such as habitat destruction and increased carbon emissions. Additionally, the disposal of these abrasive particles after use can pose challenges due to their hardness and durability.

- Potential health risks: Working with diamond slurries or cubic boron nitride compounds requires caution as they may release fine particles into the air during the lapping or polishing process. Inhaling these particles could potentially lead to respiratory issues if proper safety measures are not taken.

- Limited compatibility: Diamond slurries are primarily effective on hard materials like metals and ceramics but may not perform well on softer substances like plastics or composites. Similarly, while cubic boron nitride abrasives excel at cutting ferrous materials like steel, they may struggle with non-ferrous alloys.

- Maintenance requirements: Both diamond slurries and cubic boron nitride compounds require careful storage conditions to prevent contamination or degradation over time. During handling, special precautions must be taken to avoid introducing impurities that could affect their performance.

5. Conclusion

Diamond slurry's exceptional hardness makes it ideal for challenging lapping tasks on hard materials like metal moulds used in various industries including automotive manufacturing! Its unique qualities allow for precise surface finishing by removing imperfections efficiently!

On the other hand, cubic boron nitride slurry, although slightly less hard than diamond, it is particularly well suited for grinding ferrous metals like steel. Its high thermal stability also makes it well-suited for use in high-heat applications.

However, both diamond and CBN compounds come with their own pros and cons that should be taken into consideration before deciding on which one to use for a particular job. Diamond and CBN slurries, suspensions, and compounds can be excellent choices for lapping and polishing applications if the cost is manageable and the other drawbacks can be addressed. By weighing the pros and cons of using diamond or cubic boron nitride abrasives, users can make an informed decision that ensures superior results.

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797